Description

Viking-8S-235 Premade Pouch Fill & Seal Packaging Machine – Year 2021

Crafted with excellence, Viking Masek’s 8-station single-lane Pouch Fill & Seal Packaging Machine is a stunning illustration of their FS packaging machines.

Commissioned in 2021 for terminated gusset bags,

it has only been used for six months!

The owner has chosen to switch to fully automated VFFS baggers, putting this incredible machine up for sale.

AS&E auger filler is included. Comes with a pair of LCD touch screens, one for the machine function and the other for the printer.

See additional detail below.

This machine is reported new at

$450,000 and has an 8-month lead time for delivery.

It has been recently inspected and certified for diagnosed functionality,

it’s still commissioned and ready for an in-person demo.

Take delivery immediately!

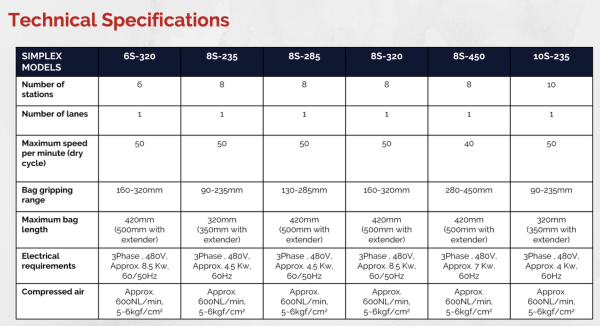

ABOUT THE VIKING MASEK 8s-235 POUCH FILL & SEAL MACHINE

MAX SPEED

50 bags per minute

BAG SIZE

Minimum: 90 mm width x 120 mm length

Maximum: 235 mm width x 350 mm length

FEATURES

• 8 stations, single lane

PLC control with two touch screens (machine & printer)

• AS&E auger filler

Servo-driven Allen Bradley control platform

Highly durable welded steel frame

Production parameter memory, including gripper size, machine speed, sealing temperature, and filling volume

Pouch presence detection – no filling, no sealing

Bag deflation with wire guide or push bars

Automatic deoxidizer feeding station

Two step sealing process guarantees clean sealing

Cooling station for liquid products

ELECTRICAL

480v 3 phase 60Hz, approx. 4.5 Kw

COMPRESSED AIR

Approx. 700NL/min,

5-6kgf/cm²

LOGISTICS

All Used Equipment Sold As-Is.

In-person inspections are recommended.

Crating and Freight NOT INCLUDED. Quoted specific to your location and needs.

Single Lane Premade Pouch Equipment

Fill and seal custom premade pouches with this single lane automatic pouch packaging machine. With eight stations, this rotary machine can package coffee at up to 50 bpm. Easy integration with volumetric, multi-head scale, auger, and cup fillers, as well as infeed and outfeed conveying equipment, makes this packaging machine a top choice for complete premade pouch packaging solutions.

VideoJet 6330 Thermal Transfer Overprinting:

• Printhead: 53mm, 300dpi (12dot/mm)

• Print area: Intermittent printing mode: 2.1” (53mm) wide x 3.0” (75mm) long

• Minimum print speed: 1.6 in./sec (40mm/sec) full print quality; 0.4 in./sec (10mm/sec) draft mode print quality

• Maximum print speed: 29.5 in./sec (750mm/sec)

• Maximum throughput: Up to 250 prints per minute

• Bar codes: EAN 8, EAN 13, UPC-A, UPC-E, Code 39, EAN 128, Code 128, ITF, RSS (including 2D composite codes), DataMatrix, QR; others available upon request

• Power supply: 100-240VAC

• Operating temperature: 0-40°C (32-104°F)

AS&E M35 Auger Filler

Head Casting

• Cast aluminum thick wall frame CNC machined for precise alignment of power train, hopper, & auger tooling

• Multiple access ports allowing for:

o Power train assembly

o Ease of installation and maintenance

o Auger height adjustment from outside hopper

Drive Train

• Auger: High performance, low inertia servo motor with spindle speed up to 1500 RPM for rapid filling

• Agitator: Cycloidal gear motor with optional VFD (as desired for product handling)

• Synchronous HTD timing belts (clean, no oiled roller chain)

• External mounted motors for better cooling and easier maintenance

• Drive train design isolates and protects motors from thrust loads

Product Hopper

• M35: Single 16-gallon stainless steel hopper with V-clamp compression ring

• Alignment tool for precisely aligning hopper to spindle (standard feature)

• Inlet (150mm / 6” round) off-the-shelf style Jacob Tubing for low cost integration into your infeed systems

• Dual, large inspection ports in lid

• On-site customizable product inlets and inspection ports (three locations)

Auger Tooling

• Designed specifically for free flowing and non-free flow products

• Standard tooling sizes #12 – 52

• Positive cut-off options for difficult-to-handle products (flapper tooling, product gate)

Operator Station (HMI)

• Location up to 50 feet away

• Heavy-duty remote pedestal control station with integrated operator interface and static scale

• Controls periodically prompt the operator for weight sampling

• Main and subsidiary screens provide intuitively obvious operation of the filler

Control Features

• Weight feedback system: Auger revolutions automatically

calculated and adjusted to achieve target weight and reduce overpack