Description

DENTON EXPLORER 14 E-BEAM Magnetron Sputtering Thermal Evaporation

The Denton Explorer-14 is a magnetron sputter deposition tool for depositing conductive metallic films.

Sputter deposition is achieved by bombarding a source material with energetic ions, typically Ar+. Atoms at the surface of the target are knocked loose, and transported to the surface of the substrate, where deposition occurs. Electrically conductive material such as Al, W, and Ti can use a dc power source, in which the target acts as the cathode in a diode system.

Sputtering of dielectrics such as silicon dioxide, or aluminum oxide requires an Rf power source to supply energy to the argon atoms. Sputter films are ideal for sidewall coverage in low thermal budget cases for contact and insulating layers over features. The Denton Explorer-14 has a 14″ D-shaped chamber with LN2 supported pumping to reach high vacuum in the process chamber.

The tools two magnetron sputtering sources are set up to allow for DC, Pulsed-DC and RF sputtering of various materials.

Capabilities

-Computer controlled recipes

-Limited film stress versatility with in film development

-LN2 supported process chamber evacuation

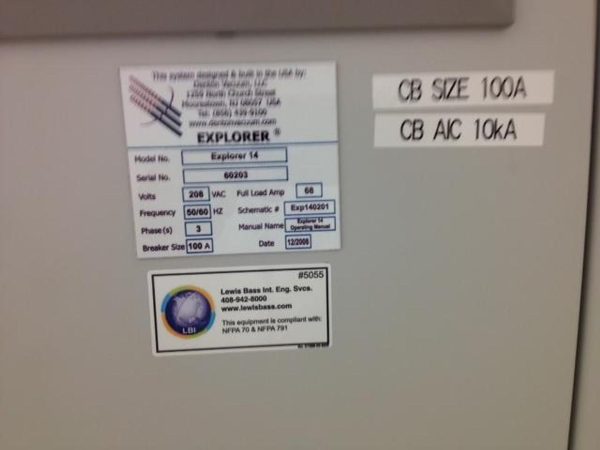

Hardware Details

-Turbo pumped chamber – upper 10-7 base pressure

-Chamber capacity: single wafer

-Two 4” Sputtering Guns

-2 DC power supplies1 pulsed-DC power supply

-1 RF power supply

-1 CTI compressor

-1 BOC Edwards dry pump

Application

-Optical film characterization & design

-Semiconductor device development

-CIGS & advanced materials research

-Advanced electron microscope sample preparation

Manufacturer Catalogue Information about

DENTON EXPLORER 14 E-BEAM Magnetron Sputtering Thermal Evaporation :

Explorer Thin Film Deposition Solution

E-BEAM, MAGNETRON SPUTTERING & THERMAL EVAPORATION

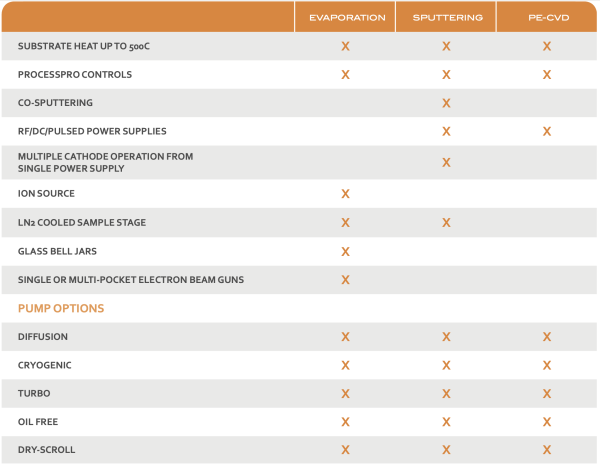

With a flexible chamber size, the Explorer can accommodate substrates as large as 8 inches. The sputtering configuration accommodates DC, Pulsed DC, and RF sputtering with co-sputtering capability. Optional proprietary PEM technology is available for closed loop control transition mode and high rate reactive sputtering of metal oxides and nitrides.

We offer multiple pumping options – diffusion, cryogenic and turbo – in rear or bottom placement providing a system that will meet your process requirements and provide the rapid pumpdown you demand for high productivity.

APPLICATIONS

Optical film characterization & design

Semiconductor device development

CIGS & advanced materials research

Advanced electron microscope sample preparation

Quality assurance

Failure analysis

HOW IT WORKS

The Explorer thin film deposition platform is a versatile high-vacuum R&D and pilot production platform that can be configured for electron beam (e-beam) evaporation, resistance evaporation, or magnetron sputtering. Ion-assisted deposition is available as an option in all three configurations. The Explorer is available in a semi-manual mode or can be upgraded to a fully automatic mode with one-push button automation to reduce system downtime

Denton Vacuum Enables Innovation And Has For Over 50 Years.

With thousands of thin film deposition tools installed globally — including a large, globally installed base of precision optical deposition systems — engineers and researchers rely on Denton’s thin film innovations to drive higher throughputs, better yields and low cost of ownership (COO) while benefiting from comprehensive service and support, and a dedicated R&D program that delivers enabling technologies.

The Explorer offers the widest range of configurations and deposition modalities in the thin film industry: electron beam evaporation, resistance evaporation, sputtering, ion plating, and ion assisted deposition.

Denton’s Thin Film Deposition Platform

• R & D • Evaporation

• Batch production • Sputtering

• In-line production

• PE-CVD

The Denton Difference

Your process is our process.

We collaborate with you to design a system that solves your exact thin film coating process needs. When we ship you a tool, it’s production ready.

• Our systems scale to meet your production requirements

• We believe in customers for life

• Worldwide support network

At Denton, We Care About Your Success

• Factory acceptance tests

• Personalized training

• Remote, real-time support

• CE/UL/CSA compliant systems

Able to Sputter

Dieletric, magnetic, and composite materials. Flexible cathodes that adjust to the impingement angle are also available.

Powerful Control System

Available in semi-manual mode or in fully automatic mode with one push automation to reduce system downtime.

Processpro upgrade offers:

1. Consistent controls across all Denton Vacuum products.

2. Standard software makes it easy to support and avoid costly customization fees.

3. Source code for your programs so you can customize your programs.

4. Network capabilities makes the Explorer

a node on your network enabling real-time, remote support and upgrades.

Typical Applications

PE-CVD

• Materials Research

• Small Batch Systems

• 3D Objects

• Coat a Variety of Materials

SPUTTERING

• Materials Research

• Product QC & QA

• Semiconductor Failure Analysis

• CD Mastering

• Nanotechnology

• Compound Semiconductors

• OLEDs

EVAPORATION

• Materials Research

• Ion Assisted Deposition (IAD)

• Medical Devices

• Telecommunications

• CD Mastering

• Lift-Off

• Protective Coating