Description

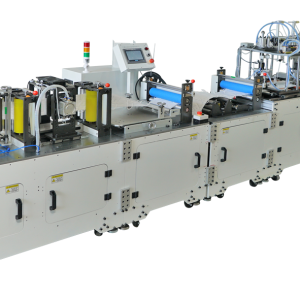

HIRSCH MASCHINENBAU Monolith COMP-E4 EPS Block Mould Machine – Year 2002

– Block mould (HIRSCH monolith COMP E-4)

– Vacuum system (HIRSCH PV19)

– Steam container (LOOS DAS)

– Cutting line.

Manufacturer Catalogue Information about

HIRSCH MASCHINENBAU EPS Block Mould Machines:

Production of high quality insulation boards

Fully automatic, vertical and horizontal EPS block moulds

HIRSCH Technology is the global market and technology leader in the production of EPS block moulds for the manufacture of high-quality insulation blocks. For more than 35 years, we have been developing innovative production processes that ensure the utmost flexibility, performance and effectiveness in production. Our patented, fully automatic, vertical and horizontal block moulds are double adjustable and guarantee significantly shorter storage times as well as minimal waste. You too can benefit from our optimally shaped blocks and long-term material savings. Discover the advantages of block moulds from HIRSCH Technology now.

Advantages of EPS block moulds from HIRSCH Technology

The innovative EPS block moulds from HIRSCH Technology offer the user numerous advantages that contribute to higher efficiency and productivity in the production of EPS insulation blocks. In addition, the EPS block moulds are extremely reliable and durable. They are made of high-quality materials and are manufactured with the highest precision. Due to these properties, they are particularly low-maintenance and offer a long service life.

Why HIRSCH Blockmolding Machines

We have the most flexible way

to optimize your block production.

Our machines have the highest level of energy saving.

We are the undisputed leader

in the horizontal blockmold technology.

We are building our machinery from user to user.

We provide turnkey plants all over the world.

Nearly 50 years in the EPS industry ensures the most experienced employees in machinery and application engineering.

Every blockmolding machine is fully tested under manufacturing conditions.

All HIRSCH blockmolds are supplied

as standard with the complete set of features required for top quality EPS block production. Flexible 4 pipe system, wedge wire screens, pre-filling hopper with active dust separator, vacuum unit, exit line for minimum 3 blocks, teleservice and remote control, telescopic steaming in moving wall (for COMP).