Description

Gerber GTxL Cutter for Industrial Fabrics – Year 2016

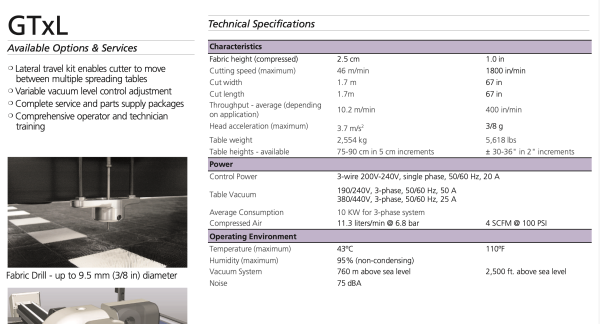

86″ (2.2m) Cutting Surface

Cutting length 1700 mm

Cutting width 1600 mm

Cutting height 25 mm

Hours under power

State excellent

Status under power

Excellent condition Gerber GTXL automated cutter with extra wide 86″ (2.2m) cutting surface.

Purchased brand new in 2016.

Manufactured in USA, not China.

Installed by Gerber technicians.

Thoroughly maintained by owners highly familiar with the machines.

All components are in solid working order.

The machine operates daily with no issues.

Equipment is available now.

Possible help with disassembly.

Buyer arranges loading & transportation.

CutWorks software not included.

Training available for an additional fee.

Manufacturer Catalogue Information about Gerber GTxL Cutter for Industrial Fabrics :

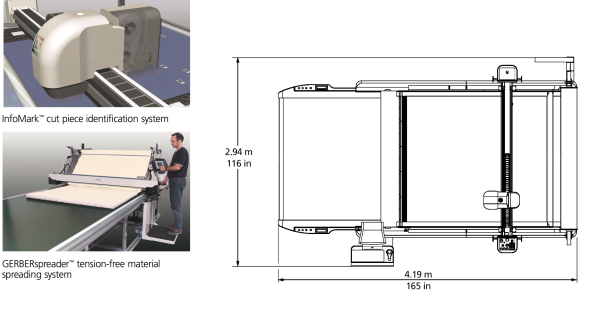

The GERBERcutter® GTxL

is a low-ply conveyorized system capable of cutting

up to 2.5 cm (1 in) of com- pressed fabric, using

Gerber’s state-of-the-art reciprocating knife technology.

A conveyorized cutting table efficiently moves material from a spreading table or single-ply roll feeder to the cutter and then directly onto the bundling area.

Get the most from your automated cutting system. Get accurately cut parts every time.

H The GTxL employs a powerful vacuum system to hold material firmly in place during the cutting process delivering cut parts that are symmetrical ply to ply.

H An optional carbide knife is available for cutting dry composite materials and other technical textiles.

H A drag knife assembly is available as an option for single-ply cutting of intricate patterns and shapes.

H Automatic SMARTbiteTM calculator analyzes each marker to determine the maxi- mum number of pieces to be cut with a minimum number of material advances to maximize cutter throughput.

H Long vertical knife strokes and automatic knife re-sharpening eliminate hanging threads ensuring quality cut parts from top to bottom ply.

H Operators can easily adjust cut speed and knife speed according to the type of material being cut to maximize throughput and eliminate fusing of certain materials.

Easy to use and comfortable to operate.

H C200 MT Windows-based cutter control software employs an intuitive graphi- cal user interface that simplifies operator training and daily use. It includes online help and built in diagnostics. Continuous, real-time, graphical display of operating parameters, vacuum level and cut speed provides a comprehensive overview of the entire cutting process.

H Easily stores cutting setup files for quick retrieval to accelerate future cut jobs. H Fully network-compatible for easy transfer of data from CAD systems.

Realize a fast return on your investment.

H The GTxL generates a report upon request that provides critical information concerning time management. Reports specify information by shift including how long the cutter was in operation, how many times operation was stopped, average cut speed, total perimeter of parts cut and more.

H Automated cutting requires less labor to generate more cut parts.

H The GTxL is designed to use longer-lasting consumables.

H An optional, intelligent, high-efficiency vacuum control lowers electrical con- sumption and associated expenses.

H With its low initial capital investment, low cost of ownership and superb accu- racy and throughput, the GTxL delivers the best price-performance in its class.