Description

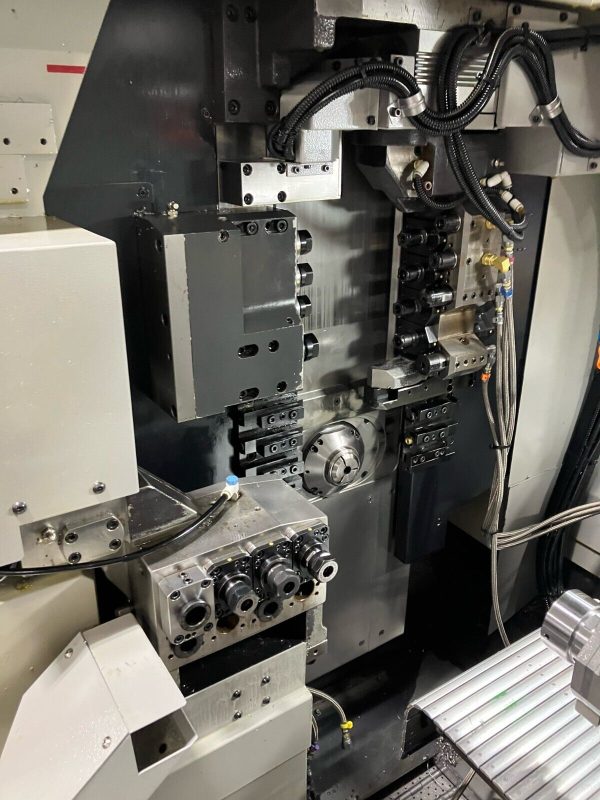

TSUGAMI SS327-5AX Super Swiss – Year 2019

CNC SWISS SCREW MACHINE

Specifications:

Machining Range:

Max. Machining Length ……….. 12.99″ Direct-Drive Guide Bushing

2.76″ Chucker Mode

Max. Main Spindle Drilling Diameter ……………………. .47″

Max. Main Spindle Tapping Diameter …………………….. M10

Max. Back Spindle Drilling Diameter ……………………. .393″

Max. Back Spindle Tapping Diameter …………………….. 1.77″

MAx. Back Drilling Diameter …………………………… .31″

MAx. Back Live Tapping Diameter ……………………….. M6

Main Spindle Speed …………………………….. 200 To 8,000 Min-1

Back Spindle Speed …………………………….. 200 To 8,000 Min-1

Tool Spindle Speed …………………………….. 200 To 6,000 Min-1

Total Tool Number (Standard Spec.) ………………. 38

Tool Size …………………….. .625″ x 3.94″ (Square) / 25mm (Round)

Rapid Traverse Rate : 35m/min (105 ft/min {x1, Y1, Y2: 24m/min (78.74 ft/min

B-Axis tool Spindle Speed ………………………. 7,000 RPM

Spindle Index ……………………………. C1 Axis and C2 Axis

Main Spindle …………………………….. 5/7.5 HP (3.7/5.5 KW

Back Spindle …………………………….. 5/7.5 HP (3.7/5.5 KW

Cross Drill Of Front Tool Post …………….. 1.5 HP

B-Axis Tool Spindle ………………………. 1.5 HP

Rotary Tool or Back Tool Post ……………… 1.9 HP

Rotary Guide Bushing ……………………… 2 HP

Z1, Y1, X2, Z2 …………………………… 1 HP

X1, Y2, …………………………………. 0.7 HP

Compressed Air Requirement ………………… 4 MPa

Power Source Requierement …………………. 16.8 KVA

Coolant Tank Capacity …………………….. 260 L

Machine Dimensions ……………………….. 103″ x 50″ x 79″

MAchine Weight …………………………… 8,818 LBS

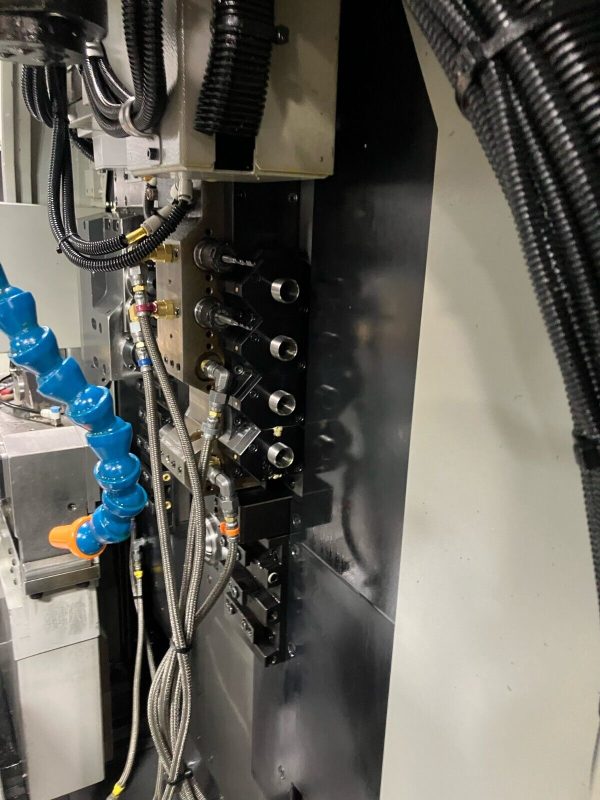

Equipped With

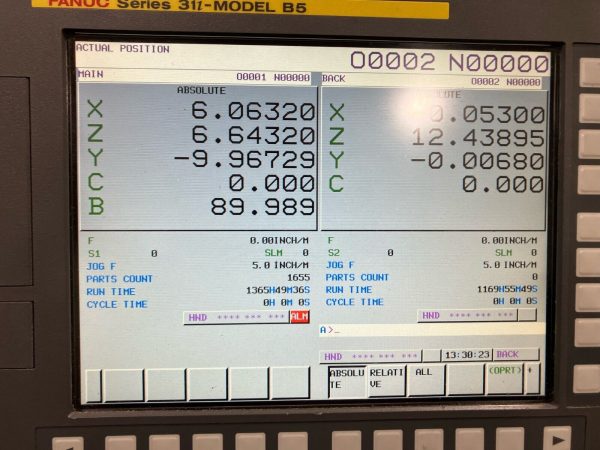

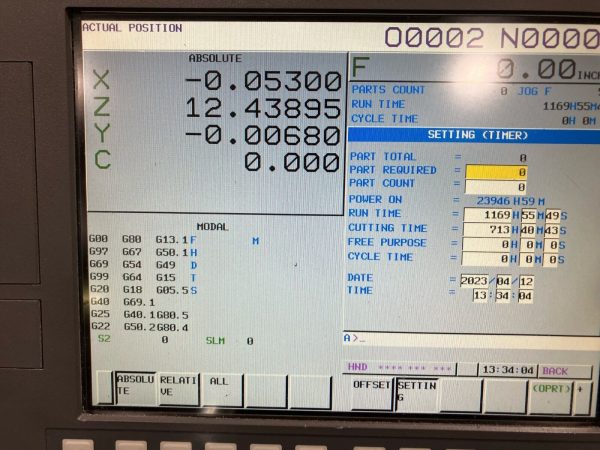

– Fanuc 31i B5, Axis Name X1/Z1/Y1/X2/Y2/C1/C2

Polar Coordinate Interpolation, Cylindrical Interpolation,

Direct Drawing Dimension Programming, Inch/Metric Conversion, Helical,

– Edge Patriot 338 Barfeeder

– Back Spindle Brake, Work Catcher, Work Conveyor, Direct Drive Rotary Guide

Bushing, Front Discharge With Air Blow, Back Tool Spindle, Back Adapter,

Drill Holder S, Drill Holder M, High Pressure Pump, Mist Dust Collector,

Y1 Axis Touch Switch, B-Axis Brake,

Key Advantages include:

– 7-axis Machining, Simultaneous 4 & 5-axis Machining with CAD/CAM

– Servo-driven B-axis Tool Spindle can machine virtually any angle drilling,

tapping, end milling

– B-axis Live Tools (four front, four rear) create sculpted shapes

– B-axis Control enables thread whirling or hobbing without dedicated

attachments

– Mutual Tool Use for Different Angles via B-Axis Control

– Modular Tool Zone, cartridge type live cross and face tools, main and sub

spindle Fanuc 31i-B5