Description

Messer TMC4500 DB – Year 2018

Heavy-Duty Dual Beam Cutting Machine

This machine was delivered and installed in 2018.

400 amp plasma, Oxy fuel

Tool changing drill spindle needs rebuilt.

Slagger and downdraft with dust collector as well.

There will be additional cost for decommissioning and loading.

Manufacturer Catalogue Information about

Messer TMC4500 DB Heavy-Duty Dual Beam Cutting Machine:

The TMC4500 DB workhorse and industry leader when it comes to excellence in thermal cutting.

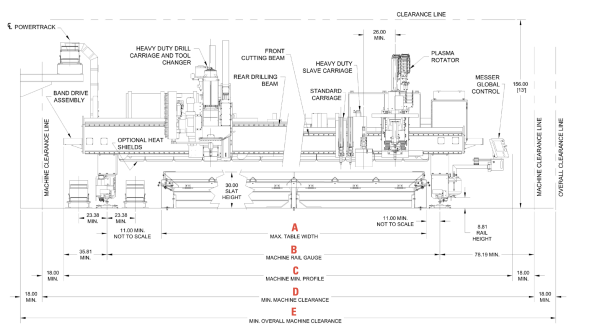

The TMC4500 DB is a heavy-duty dual box-beam constructed gantry cutting machine, built to perform in your rigorous production environments. Finite Element Analysis (FEA) design methods assure that your TMC is up to the task of cutting with multiple plasma and oxy-fuel torches.

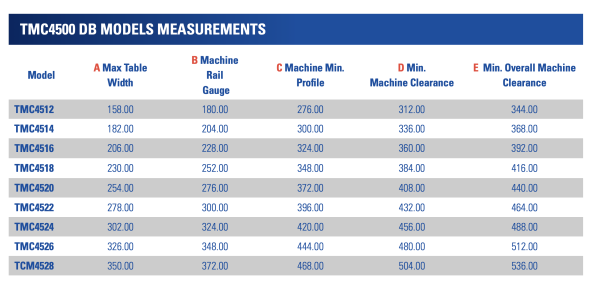

Cutting widths from 12′ (3.657m) to 28′ (5.534m).

Cutting lengths up to 200′ (60.96m).

Positioning speeds up to 1,400 ipm.

Drilling up to 4″ (101.6mm) diameter and tapping up to 1 1/2″ (38.1mm) diameter.

Massive dual gantry process beams provide superior bending, and torsional strength for any tool combination selected.

Precision Linear Y-Axis way system with wide spacing to provide rigid support for several process tools.

Global ControlPlus, Windows® based with easy-to-use operator interface.

Virtual Service™ remote consultation and diagnostics.

Machine motion accuracy ± 0.015″ in 72″ travel with .010″ repeatability measured with a laser interferometer.

High-speed Messer Cutting Systems programmable lifters

TMC4500 DB

Messer Cutting Systems TMC4500 DB heavy-duty dual box-beam gantry cutting machine is built to perform in rigorous production environments. Finite Element Analysis (FEA) design methods assure the machine can cut with multiple plasma and oxyfuel torches. The TMC4500 DB can be equipped with multiple plasma and oxyfuel beveling options. These units can produce K, V, X, Y, I bevels. Bevel angles ranging from 15° to 60° for oxyfuel, and +45° to -45° for plasma.

The TMC4500 DB supports drilling up to 4” and tapping of 11/2” diameter holes. A wide variety of plate marking tools can be added to help you save time by cutting and marking on one piece part.

This durable heavy-duty workhorse has proven its dependability in the demanding surroundings of shipyards, service centers, contract shops, and OEM manufacturers.