Description

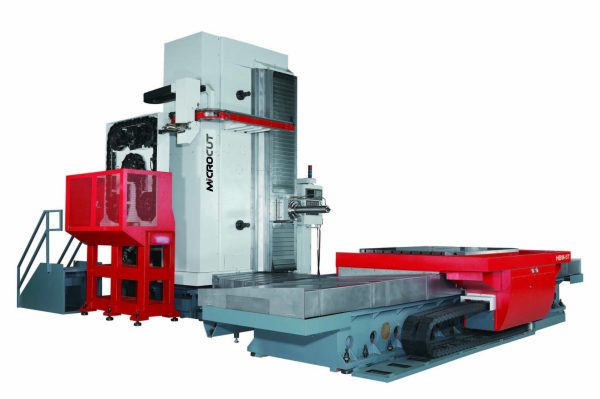

Microcut HBM-5T – Year 2018

CNC 5 axis Boring Machine 4.5 Meters

| CNC | Fanuc |

| X travel | 4500 mm |

| Y travel | 2600 mm |

| Z travel | 1400 mm |

| Table length | 2500 mm |

| Table width | 2500 mm |

| Max. workpiece weight | 20000 kg |

| Spindle taper | BT 50 |

| Spindle diameter | 130 mm |

| Overhauled | no |

Microcut HBM-5T 5 axis cnc boring machine

5 axis

Control unit : FANUC 31

X: 4.500

Y : 2.600

Z : 1.400

Spindle diameter : 130 mm

Machine is in excellent condition

Manufacturer Catalogue Information about

BUFFALO MACHINERY Microcut HBM-5T CNC travelling column boring and milling center :

| ITEM | UNIT | HBM-5T |

| X axis table cross travel | mm | 3500 (std); 4500/5500 (opt) |

| Y axis headstock vertical | mm | 2600 |

| Z axis column long travel | mm | 1400/2000 |

| Quill diameter) | mm | 130 |

| W axis (quill) travel | mm | 700 |

| Spindle power | kW | 37/45 (std) |

| Max. spindle speed | rpm | 35-3000 |

| Spindle torque | Nm | 1942/2362 (std) |

| Spindle gear range | 2 step (1:1 / 1:5.5) | |

| Table size | mm | 1800 x 2200 |

| Rotary table indexing degree | degree | 0.001° |

| Table rotation speed | rpm | 1.5 |

| Max. table loading capacity | kg | 15000 (std) / 20000 (opt) |

| Rapid feed (X/Y/Z/W) | m/min | 10/10/10/8 |

| ATC tool number | 60 | |

| Machine weight | kg | 49000(std); 51500/54500(opt) |

HBM-5T travelling column boring and milling center with powerful gear box driven spindle dia. 130 mm provides high-speed with excellent power and torque. The machine’s flexibility makes it useful for a variety of workpieces with loading capacity up to 20000kgs. The machine can be equipped with a wide selection of technological accessories that significantly expands the usability of it. Either Fanuc, Heidenhain or Siemens controls can be selected.

1. Column moving bore providing 130mm diameter ISO50 spindle taper

2. Extremely large working capacity with fixed Ram head.

Standart Accessories :

Spindle and servo motor package

Large fully ground work table with 11 T-slots

Precision ground ball screw

Heavily ribbed cast iron components

Telescopic way cover

Automatic central lubrication

Coolant system

Chip drawers

Telescopic way covers

Optional Accessories:

Universal head

Right angle milling head

Spindle extension sleeve

Coolant Through Spindle Device

User operation station

Table guard for CTS function

Oil skimmer

Angular block

Chip conveyor

Air conditioner for electric cabinet

Safety module

Lifting device