Description

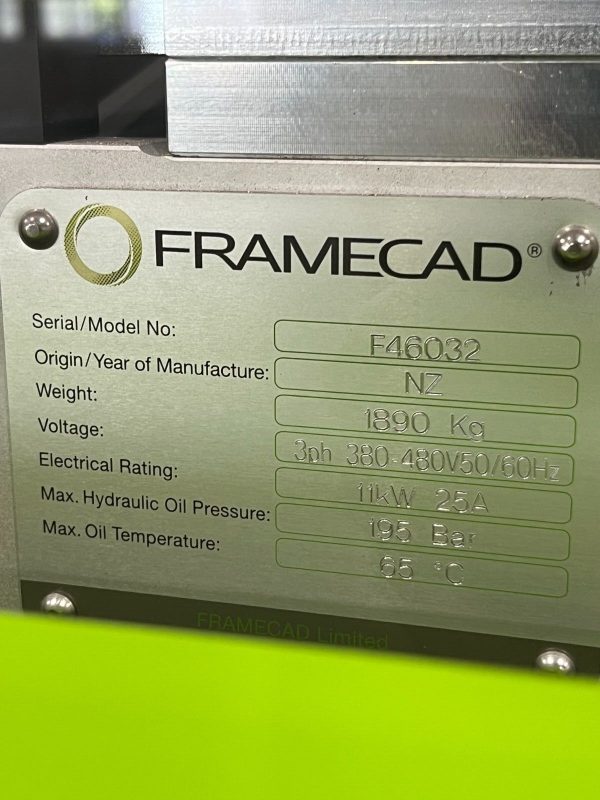

FRAMECAD F450iT Steel Roll-Forming Machine

Lightly Used (Perfect Condition)

|

|

|

|

|

|

Specifications:

| F450iT | |

|---|---|

| Profile Width (Web) | Range 75 – 150mm or 3″ – 6″ |

| Profile Height (Flange) | Range 34 – 50mm or 1⅟₃” – 2″ (Boxable Section reccommended) |

| Material Thickness | 0.70 – 1.6mm or 22 – 16 gauge |

| Roll Forming Stations | 11 Auto Gauging stations |

| Punching Stations | 12 Frame and Truss Punching Stations |

| Standard Punch Tooling* | Service Hole, Web Bolt Hole, Dimple, Web Notch, Chamfer, Lip Cut, Flange Holes (left & right), Swage, Shear. (options to add Flange cut left and right)* |

| Max Line Speed | 2,160m/hr (7,090ft/hr) |

| Typical Production Speed (actual dependent on framing design) | Joists: 300 m/hr (985 ft/hr) Walls: 700 m/hr (2,300 ft/hr) |

| Main Drive Power | 7.5kW (10hp) |

| Hydraulic Power | 5.5kW (7.4hp) |

| Length | 4,500mm (14.76′) |

| Width | 800mm (2.65′) |

| Height – to top of covers | 1200mm (3.95′) |

| Weight (approx.) | 2,194kg (4,837lb) |

| Printer | 2 Printer Heads |

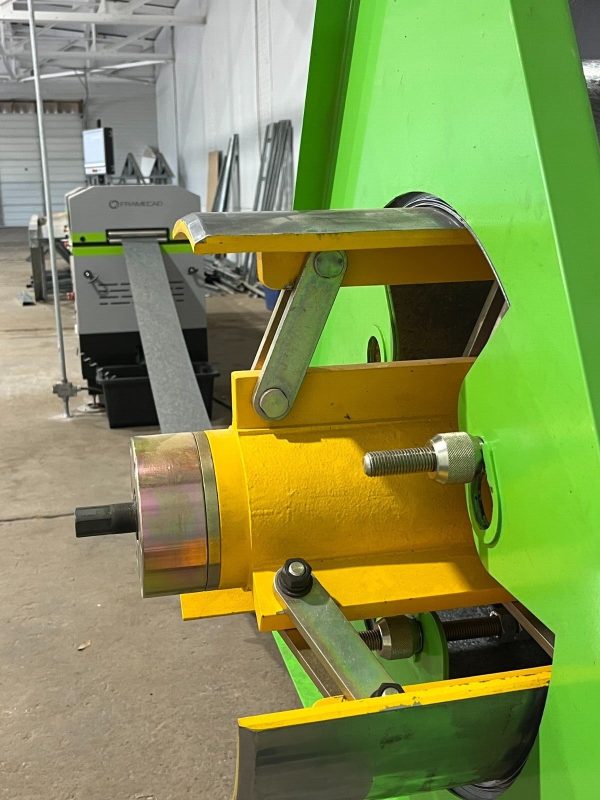

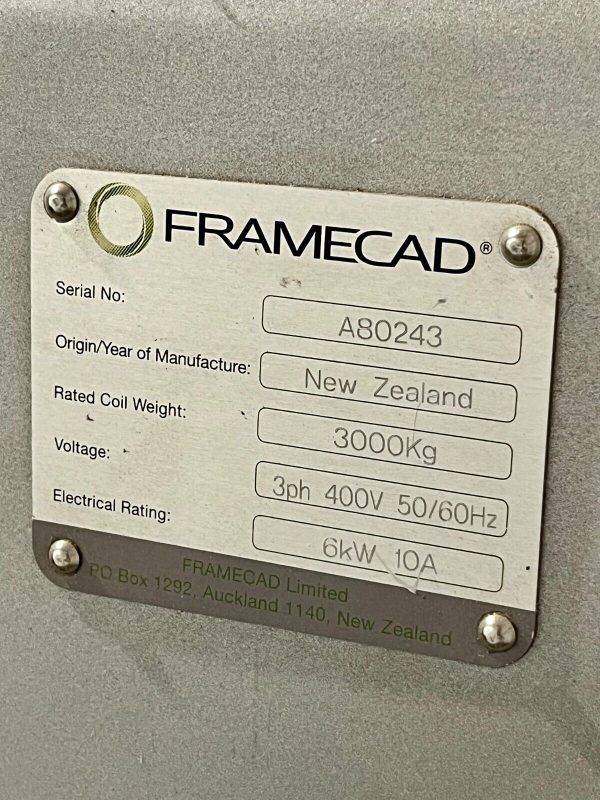

| Decoiler Capacity | 3,000kg (6,600lb) powered Decoiler |

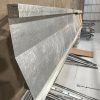

A rapidly high-performing solution for producing framing and trusses in heavy residential and light commercial buildings. The FRAMECAD F450iT has been designed to handle the heavy gauge steel required to construct 1 to 7 storey structures and outputs 75–150 mm profiles. Suitable for heavy high walls, heavy trusses, heavy flooring, and short span flooring; the F450iT is an all-round roll forming solution.

The framing product produced by the F450iT is a boxable section, making assembly for heavy building requirements easier. The F450iT offers full framing capabilities with 11 tooling punches and the option of an additional custom tool (on request at time of purchase of manufacturing system).