Description

Mitsubishi EA12D – Year 2012

CNC Sinker

Specifications:

Machining Stroke – 15.7″ x 11.8″ x 11.8″

Worktank Internal Dimensions – 41.3″ x 27.5″ x 17.7″

Dielectric Fluid Level (Max / Min) – 15.7″/ 7.0″

Max Workpiece Dimensions – 39.3″x 25.5″ x 13.7″

Max Workpiece Weight – 2,200 lbs

Table Dimensions – 27.5″ x 19.6″

Table to Platen Dimension – 11.8″ x 23.6″

Machining Movement (C) – 360 Degrees

C-Axis Increment – 0.001 Degree

Min Command Input – .00001″

Resolution – .000002″

Tank Type – Fixed Tank

Worktank Access – Front Drop Door

Maximum Current – 60 Avg Amps / 80 Peak Amps

Graphic Display – 10.4″ TFT Color LCD

Power Requirement – 200-220/3/60

Max Electrode Weight – 110 lbs / 11 lbs with C-Axis

Shuttle Type AEC – 20 AEC

Rapid Traverse – 78.74 IPM

Dielectric Capacity – 132 Gal

Installation Dimensions (W x D) – 91.5″ x 87.2″

Total Shipping Weight – 6,889 lbs

Machine Tool Dimensions (L x W x H) – 72.4″ x 80.7″ x 93.5″H

Equipped With:

* Mitsubishi M700 64 Bit Fuzzy Logic CNC Control W/14″ LCD

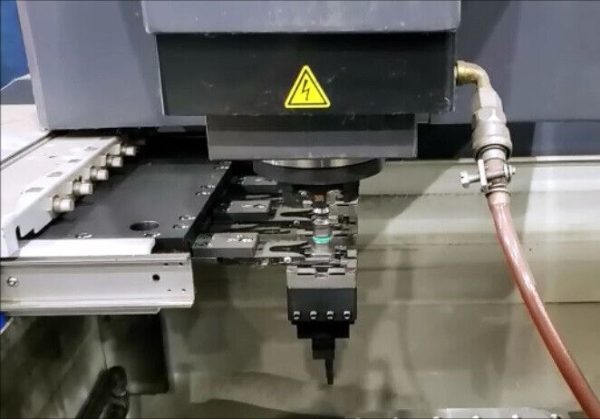

* C Axis (System 3R Combi)

* 4/7 Position Automatic Tool Changer (System 3R Macro/Macro Jr)

* High Speed Jump Cycle

* Fuzzy Pro3 Plus Orbit Pro

* E.S.P.E.R. Programming

* Fixed Table Traveling Column Design

* Rotary Glass Scales(X,Y), Linear Glass Scale(Z)

* 80 AMP FP60EA Power Supply

* Remote Hand Controller

* Auto Lubrication

* 10MB User Program Storage On Hard Drive

* RS-232C Port and Ethernet Port for DNC

* Auto Fill & Drain

* Dielectric Tank With Pump and Filtration

* Electric Chiller

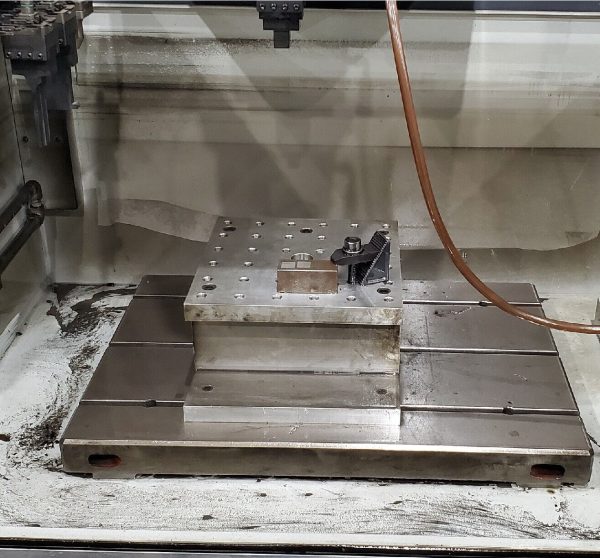

* Sub-table fixture included

* All Available Manuals and Accessories

3R tooling pictured is NOT included with the machine.

1 Available

Mitsubishi EA SERIES features:

Fuzzy pro emulates an experienced operator optimizing the burn process from rough to finish orbit.

High-speed jump creates the ability to do most burns with no flush.

Saddle-less column movement system uses a special combined linear motion way system.

New digital AC Smart Servo System improves resolution to 0.05 µm (2 millionths inch) speeding response time.

Fine Pulse 2 (FP2) function which operates in a pumping action to keep the gap clean, improves finish and reduces the power consumed.

SC circuit reduces electrode wear by enacting pulse discharge during high-precision machining.

PS circuit provides accurate finish by controlling surface pulse discharge.