Description

Dugard Eagle 660 VMC – Year 2007

| Axis X | 660 mm |

| Axis Y | 520 mm |

| Axis Z | 510 mm |

| Rotary table (4th axis) | no |

| Type of CNC | Siemens Sinumerik 810 D |

| Table length | 810 mm |

| Table width | 510 mm |

| Max. part weight | 500 kg |

| Number of tool pockets | 24 |

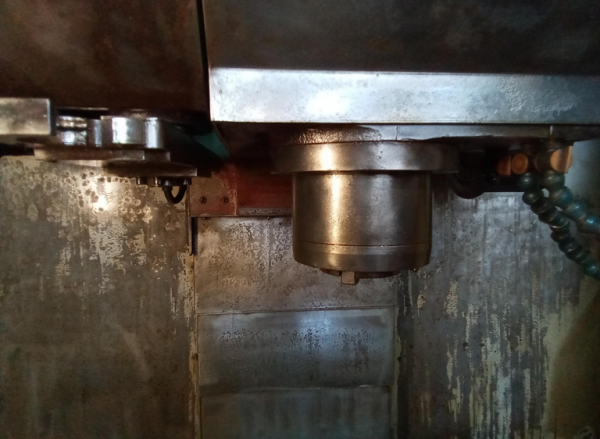

| Spindle taper | ISO 40 |

| Max. spindle speed | 8000 rpm |

| Spindle motor power | 5.5 kW |

| Dugard Eagle 660 VMC | |

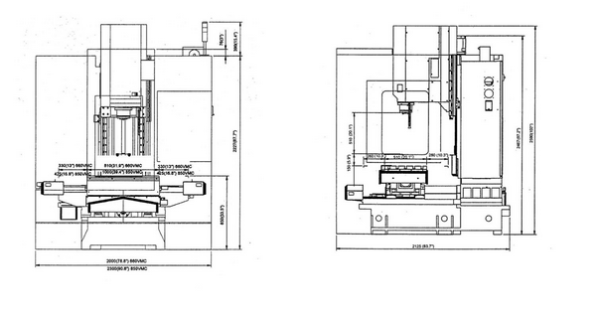

| Length x width x height | 2000.0 × 2060.0 × 2583.0 |

| Weight | 5000 kg |

Technical data of the DUGARD EAGLE 660 VMC CNC milling machine

– feeds in the X/Y/Z axis: 660/520/510 mm

– feed speed in the X, Y, Z axes: 1-10000 mm/min

– accelerated feed in the X, Y, Z axes: 30/30/24 m/min

– work table surface (length x width): 810 x 510 mm

– maximum detail weight: 500 kg

– minimum spindle speed: 80 rpm

– maximum spindle speed: 8000 rpm

– spindle cone: ISO 40

– spindle power (continuous power/MTDR): 5.5/7.5 kW

– minimum distance between the spindle tip and the work table: 150 mm

– maximum distance between the spindle tip and the work table: 660 mm

– maximum tool diameter: 76 mm

– maximum tool length: 250 mm

– maximum weight of the tool with the holder: 7 kg

– tool selection method: bidirectional, programmed using an intermediate arm

– positioning accuracy: ± 0.014 mm

– repeatability accuracy: ± 0.01 mm

– working pressure: 5 bar

– air consumption: 200 l/min

– coolant pump power: 0.76 kW

– power demand: 15 kVA

– noise level: 72.2 dB (A)

– dimensions (length x width x height): 2000 x 2060 x 2583 mm

– machine weight: 5000 kg

Equipment for the DUGARD EAGLE 660 machining center

– CNC controller: SIEMENS SINUMERIK 810 D

– 24-position tool magazine

– shavings tub

– lubrication system

– compressed air system

– oil cooler

– main switch

– lighting of the working space

– electrical cabinet

– user manual

– Operation and Maintenance Manual – Technical and Operational Documentation

DUGARD EAGLE 660 VMC CNC vertical machining center was manufactured in 2007 in Taiwan. A machine with wide machining capabilities used in production plants enables precise milling, drilling, threading, boring and cold reaming of details using rotary tools. All types of machining are programmed in the intuitive SIEMENS SINUMERIK 810 D CNC control, which performs fully automatic machining cycles and minimizes the need for the operator to operate the machine.

The extremely stable base of the milling center provides stiffness and support for the guides along which movement is carried out in the X, Y, Z axes. The DUGARD CNC machining center automatically stores and replaces tools from a 24-position magazine, ensuring the shortest possible access path to a given tool. To also ensure a high level of safety, the machine’s structure is equipped with specially designed sliding covers that protect the operator from moving parts, coolant and fragments of processed details. The EAGLE 660 milling center weighs 5,000 kg.