Description

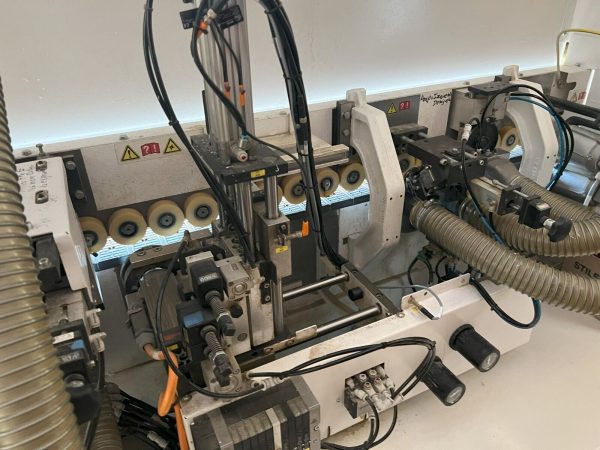

Homag Edgeteq S-240 – Year 2020

Optimat Automatic Edgebander with pre milling and corner rounding

Homag Edgeteq S-240 Optimat automatic Edgebander is a top-of-the-line straight line edgebander from Germany. It’s perfect for professional woodworkers who want to create high-quality edges with precision and speed. The machine includes pre-milling and corner rounding which give you more flexibility in producing parts with smooth edges and corners. Homag, is known for its reliable and durable equipment. Ideal for those who are looking for a reliable and efficient way to create high-quality parts.

The Edgeteq is built to withstand the most challenging applications.

Rigid chain track

Industrial chain and industrial pads

Round and flat guidance

Automatic magazine for strip and coil feeding

Line-controlled guillotine

Large 800mm diamter coil table with rollers

Will support up to 3mm PVC Coils

Edge strip capacity is 0.4 – 3mm

230V 3 phase

Quick Change Glue Tank

Pressure Rollers

Guillotine

Dual Motor End Trim

Fine Trimming

Corner Rounding

Quick Change Profile Scraping

Flat Scraping

Buffing

Front and Rear Cleaning Sprayers Liquids

(2) Motor Pre-milling (3 HP- 12,00 RPM) Diamond Cutters

Hotmelt granulate glue application system with approx. 12-16 Min heat up time;

automatic reduction of glue temperature when idle more than 15 Min.

Automatic magazine for strip & coil (large coil table 800 mm dia. to accommodate large coils of 3 mm PVC)

3 mm PVC guillotine

(1) drive plus (2) split secondary roller “pneumatically controlled” pressure sections.

End trim (0.25 HP – 12,000 RPM motor ea.), chamfers 0° – 15°, from straight to bevel.

Top & bottom flush/bevel/radius trim, bevels 0° – 15° (0.5 HP – 12,000 RPM motor ea.

Corner rounding unit for top & bottom corners (0.5 HP – 12,000 RPM motor).

Top & bottom scraping for 2 – 6 mm straight scraping. External collection box

Top & bottom buffing (0.25 HP – 1,400 RPM motors)

230V 3 Phase