Description

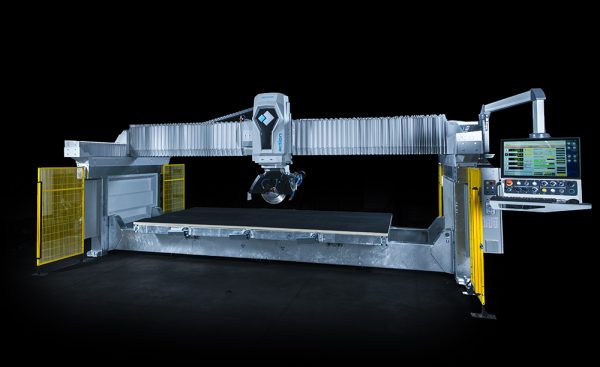

Denver Action Monobloc Bridge Saw Machine – Year 2022

SPECIFICATIONS:

– Motorized head rotation (C axis),driven by brushless motor. Head rotation is

controlled and displayed on the control panel

– “X”,”Y”,”Z”,”C” axes interpolation white Brushless motors.

– Precision control unit with 21” colored touch-screen. Programmer for the automatic

work cycles in manual / semi-automatic / automatic mode for orthogonal / diagonal /

step cutting cycles

– On board touch interface: LOGITOUCH powered by DDX

CAD Dot to Dot

Osai process controller to monitor Processing and machine parameters

Import of single and multi-layer DXF file single slab

Processing and management of remaining pieces on subsequent slabs

Manual and automatic nesting with vein matching (book matching)

Single or multiple, straight and / or curved cuts with continuous X, Y, C interpolation

and Z (positioning only)

Manual and automatic cuts

Stop processing with slab manual movement

Cut-out cycle and / or internal corners and with cutter and / or core bit

Tool path simulation with visualization of the workbench, slab and disc.

– Guard disc diam 500 mm (min. diam 350 mm)

– Manual head inclination (A axis) till 90°, with adjustable and removable backstop at

45° (+/-1°);

– Variable spindle speed for disc MOTOR

– Pendant remote control

– Red Laser positioned on the blade guard for the indication of the cut line

– Cross laser to ease the location and storage of the origin position of the work piece

and linear templates.

– NET and USB ports for program updatings

– Electric water valve & flowmeter to control the water supply

– Hot zinc coated structure, frame and table

– Service wrenches, manual greasing pump and instruction booklet

– Y-axis extended travel to 2650mm / 104″

– Hp 17,5 (S6) disc motor with adjustable spindle speed till 6000 rpm’s and interchangeable Easypin insert with 1/2 gas right thread

Manufacturer Catalogue Information about Denver Action Monobloc Bridge Saw Machine :

Action is a modern monobloc bridge saw with tilting head and hot zinc coated frame for an exceptionally long-lasting sturdiness and accuracy. It features 4 interpolated axes travelling on steel guideways with revolving balls and steelbands with revolving rollers protected by bellows and lubricated by a centralized system. To ensure high stiffness and positioning accuracy the machine is equipped with brushless motors for 4 axes movement and a ” no-play” reducer on the C axis.

The 0°-90° tilting head with adjustable 45° reference stop along with the 0°-180° rotation ensure a highly productive and versatile machine with the highest degree of comfort for the operator.

The machine is equipped with a software interface performing, smart and intuitive programming by icons and with software library with available bidimensional artifacts. With enables options, and thanks to brushless motor rotation of the head can reach C360 °, furthermore by spindle equipped with ½ gas fitting, Action can perform machining with tools and grinding wheels Just like a CNC machine.