Description

Mazak SQT 100 MSY CNC Turning Center Big Bore with bar feeder for sale.

This machine was originally bought by a prototyping company and they used it lightly until 2016.

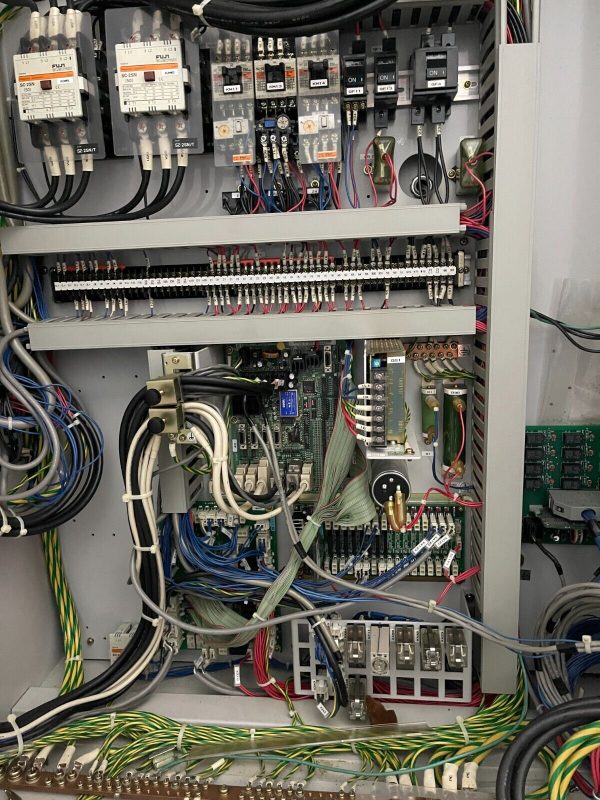

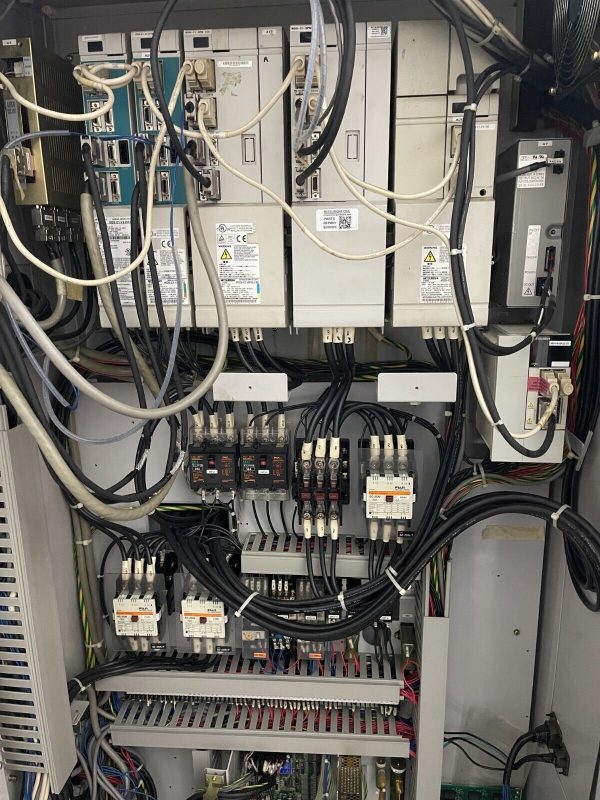

They Took backups of the entire machine parameters and system and put it in storage until 2021 when I bought it. I installed new batteries and downloaded the backups and it was up and running. The Machine is very clean, on some spots there is still the anti rust Grease that comes on new machines. It is very accurate, I can hold .0003 on it easily.

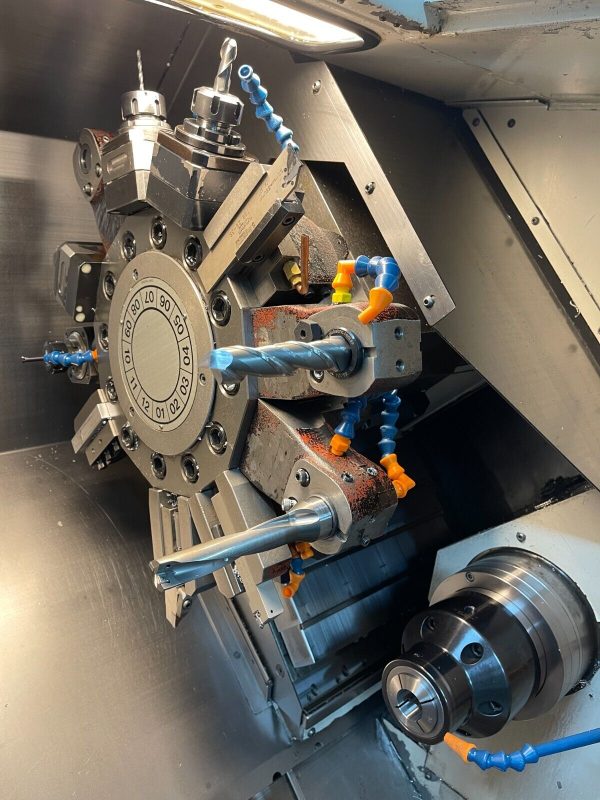

· Big Bore Option – Spindle Tube allows for 2 inch bar stock

· Chip Conveyor

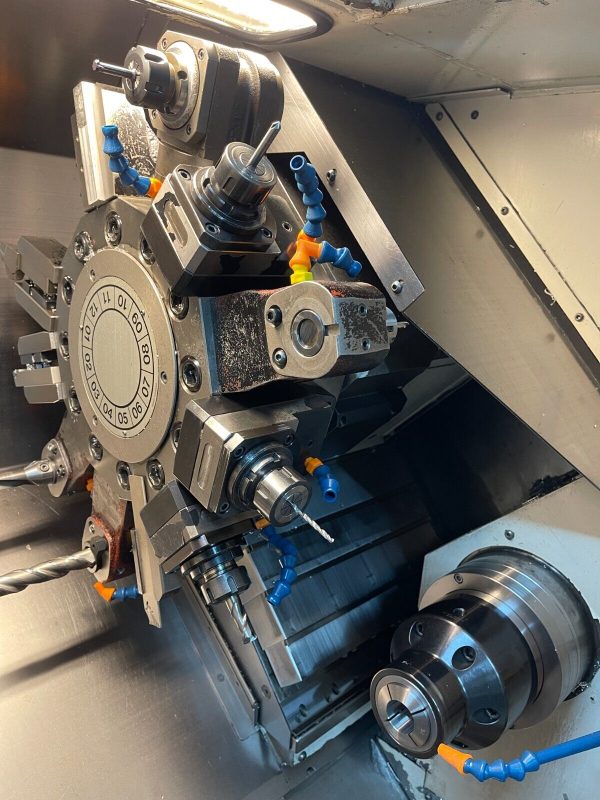

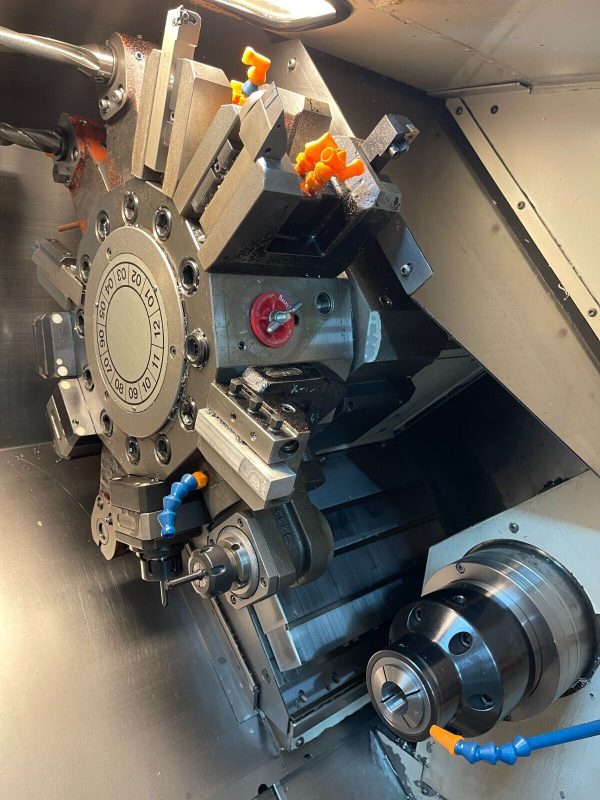

· MSY Option meaning it has the milling option,Y Axis movement, and a Sub Spindle

· Automatic parts Catcher

· Automatic Bar Feeder – It has A Space Saver 2003 bar feeder installed. The interface and bar feeder work perfectly, I use it often. It allows for all sizes of bar stock. I have a manual for it if yo uwould like it.

· Spindle Liners – I have many spindle liners for it. Most are the nice steel type and three are plastic trusty cook type.Sizes 3/8, ½, 5/8, ¾, 1, 1 1/8, 1 ¼, 1 3/8, 1 ½, 1 5/8, 1 ¾. All are in greatShape.

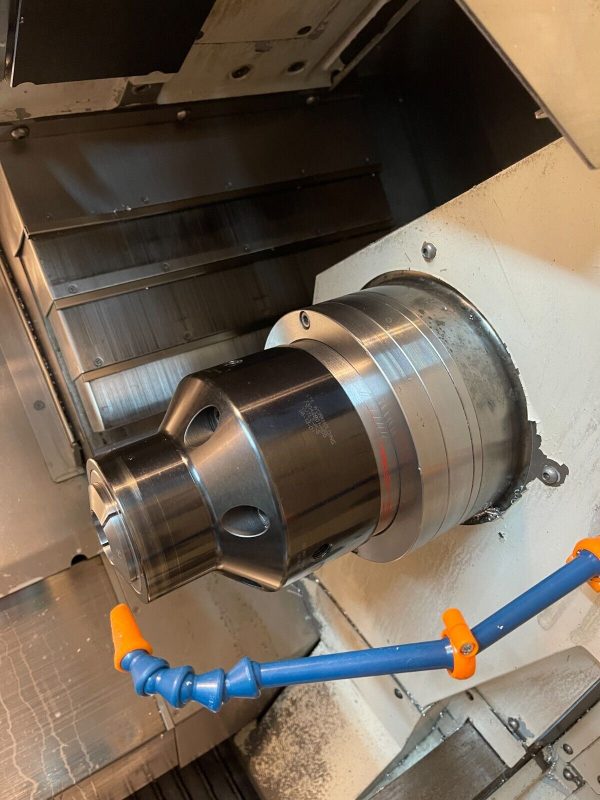

· 3J Collet Chucks – As you can see in the pictures I currently have a royal collet chuck on the main spindle, it will not be included. But I will include the 3J collet chuck it came with when I bought it. It is very similar to so sub spindle chuck. I will also include all (around14) 3J collets I have, along with the collet thread tool and a collet part ejector which threads into in inside of any collet for the second spindle.

· Part Conveyor – This part conveyor works awesome. It is designed to take parts from the parts catcher and move them so they wont get damaged. It is currently set up so that every time the parts catcher is engaged the stepper motor on the conveyor turns on. The motor has a timer that is adjustable to allow for different part sizes. It runs very slowly until the timer stops it. This allows for all night production and a conveyor full of parts when you come in the next morning. It has a drip pan with a hose that feeds back into the coolant tank so that there is no coolant mess.

· Tool Holder – All tool holders in the pictures come with the machine. Note: Actual cutting tools are not included

· This machine is unique in that, it was Builtin the factory in Japan.

· I have all available manuals for the machine and they are in great condition.

· The second spindle on this machine is in great shape. It is very quiet and runs smoothly.