Description

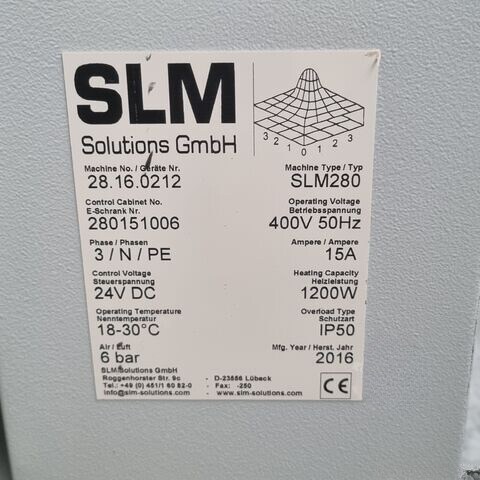

SLM Solutions Gmbh SLM280 3D Metal Printer – Year 2016

The machine need to be repaired by SLM.

Ideal for medium to high volume metal part production and prototypes, the robust second generation SLM280 selective laser melting system

offers a 280 x 280 x365mm build envelope and patented multi-beam laser technology with up to two fiber lasers exposing the build field via 3D

scan optic. Multi-laser systems can achieve build rates 80% faster than a single laser, and patented bi-directional powder recoating minimizes

manufacturing time by reducing the number of passes required to lay fresh powder during a build.

Outfitted with a standard PSM powder sieve, overflow bottles transfer material between sieve and machine reducing operator contact with

loose powder. PSM sieves and powder change kits allow users material flexibility while maintaining powder quality in an inert atmosphere.

Metal 3D printing with multiple lasers and closed-loop powder handling. The SLM280 is ideal for medium to high volume metal additive manufacturing part

manufacturing part production and prototypes.

– 280 x 280 x 365mm build envelope

– Multi-laser (twin)

– Multi-material

The machine is in a very good condition, it has been in air-conditioned room with environmental control its whole life and has only been used for

individual project and only with titanium powder

SLM280HL double laser – Effective build volume: 280 x 280 x 365mm

– Multi-laser (twin)

– Both lasers do not overlap

– The machine has been upgraded with the SLM improved laminate

flow in 2021

– The machine has integrated powder vacuum

– The machine has powder cycling ability and can automatically

resupply itself from the sieved powder deposit of the sieving unit.

– Open Parameters

– Possible Build Materials: Stainless Steel, Tool Steel, Cobalt-, Chromium-, Super Alloys, Super Alloys, Cobalt- and

Chromium, Super Alloys, Aluminum and Titanium

– The machine has only been used with titanium powder

Sieving unit PSH100 – Sieve in good conditions and has only been used with Ti6Al4V

– Unit together with SLM unit has powder cycling ability

SLM280 equipment for additive manufacturing

Page 2/3

3. Market reference parts description

Different parts are shown below:

Market reference Notes and thoughts to consider

SLM280HL double laser – Effective build volume: 280 x 280 x 365mm

– Multi-laser (twin)

– Both lasers do not overlap

– The machine has been upgraded with the SLM improved laminate

flow in 2021

– The machine has integrated powder vacuum

– The machine has powder cycling ability and can automatically

resupply itself from the sieved powder deposit of the sieving unit.

– Open Parameters

– Possible Build Materials: Stainless Steel, Tool Steel, Cobalt-, Chromium-, Super Alloys, Super Alloys, Cobalt- and

Chromium, Super Alloys, Aluminum and Titanium

– The machine has only been used with titanium powder

Sieving unit PSH100 – Sieve in good conditions and has only been used with Ti6Al4V

– Unit together with SLM unit has powder cycling ability

Chiller – Standard Chiller Unit in very good condition

AMC330 vacuum – AMC330 powder vacuum APEX in a very condition

Kaeser filter – Standard Kaeser filter in a very good condition

Powder silos – Two powder silos in a very good condition

Powder containers – Powder containers in a very good condition

Ti6Al4V grade 5 and 24 – < 50 kg (7 years old) for grade 5 – > 100kg (2- 4 years old) for grade 24

Manufacturer Catalogue Information about

SLM SOLUTIONS SLM®280 2.0 Metal 3D printing Machines :

Metal 3D printing with multiple lasers and closed-loop powder handling. The SLM®280 2.0 is ideal for medium to high volume metal additive manufacturing part production and prototypes.

- 280 x 280 x 365 mm build envelope

- Multi-laser (twin)

- Multi-material

SLM®280 2.0

Ideal for medium to high volume metal part production and prototypes, the robust second generation SLM®280 2.0 selective laser melting system offers a 280 x 280 x 365 mm build envelope and patented multi-beam laser technology with up to two fiber lasers exposing the build field via a 3D scan optic. Multi-laser systems can achieve build rates 80% faster than a single laser, and patented bi-directional powder recoating minimizes manufacturing time by reducing the number of passes required to lay fresh powder during a build.

Outfitted with a standard PSM powder sieve, overflow bottles transfer material between sieve and machine reducing operator contact with loose powder. PSM sieves and powder change kits allow users material flexibility while maintaining powder quality in an inert atmosphere.

Multi-laser Technology

The SLM®280 can be equipped with up to two 700W fiber lasers to accelerate the printing process of many metal additive powders.

Highest Productivity

Patented bi-directional powder recoating helps reduce manufacturing time by depositing a new layer of powder in both directions without having to return to a “home” position.

Material Flexibility

Paired with a Powder Sieving Machine (PSM), the SLM®280 offers material flexibility. Manual sieves allow efficient material changeover for adaptable production while maintaining safety and quality