Description

Technical specifications:

capacity

TSUGAMI B0126E-III

Rod diameter Ø 3 mm ~ Ø 12 mm

Max. Machining length 210 mm / 80 and 170 mm for rot. Guide bush

Main spindle Max. Drilling Ø 7 mm

Max. Thread Ø M6 x 1

Counter spindle Max. Bar Ø Ø 12 mm

Max. Drilling Ø 7 mm

Max. Thread Ø M8 x 1

Cross slide front Max. Drilling Ø 6 mm

Max. Thread Ø M5 x 0.8

Max. Disc diameter –

Cross machining

back Max. drilling Ø 6 mm

Max. Thread Ø M5

Spindles, tools and axes

TSUGAMI B0126E-III

Main spindle speed 200 ~ 12,000 min-1

Counter spindle speed 200 ~ 12,000 min-1

Live tools / main page 200 ~ 8,000 rpm

Live tools / rear side 200 ~ 8,000 min-1

Main spindle positioning C-axis

Counter spindle positioning C-axis

Number of tools cross slide turning 6

Driven 3

Drilling 4 + 4 (front / back)

Number of tools on the rear side Drilling 4 x on the front

number of

Tools rear side Driven 2 x front side / 2 x across

Turning holder shaft dimensions 12 x 12 x 85 mm

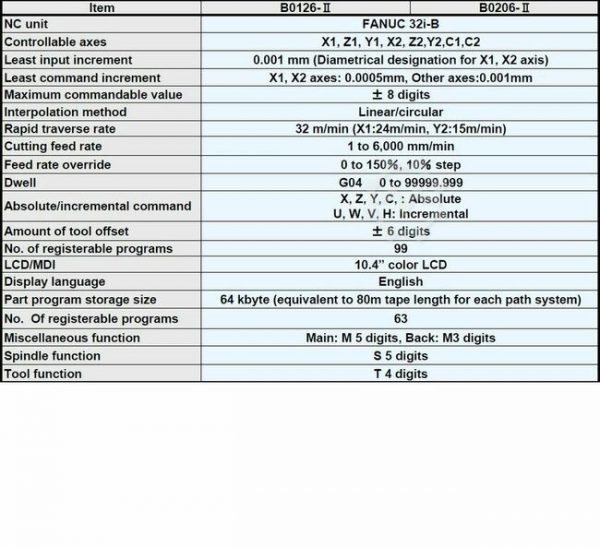

Rapid traverse 32 m / min (X1 24 m / min)

Controlled axes 8 axes

Drive power

TSUGAMI B0126E-III

Main spindle 1.5 / 2.2 kW

Counter spindle 1.5 / 2.2 kW

Driven Tools / main page 0.50 kW

Driven Tools / rear side 0.75 kW

Axes (X1, X2, Y1, Y2, Z1, Z2) 0.50 kW

Coolant pump 0.18 kW

Central lubrication pump 3 W

Physical data

TSUGAMI B0126E-III

Net weight approx. 1,750 kg

Connected load 11 kVA

Compressed air connection 4 bar and more

Compressed air consumption 30 NL / min

Tank capacity 115 liters

Height of the spindle center from the floor approx. 1,000 mm

Height of the machine 1,700 mm

Length of the machine 1,640 mm

Width of the machine 1,120 mm

Electrical connections

200 V, 50 Hz, 3 phases

Main transformer, input voltage 400 volts

Output voltage 200 volts

control

CNC path control FANUC 32i-B

2-channel control

LCD color monitor 10.4 ”

Memory card

RS232 interface

USB interface

Ethernet interface

Standard accessories

chip conveyor

Counter spindle flushing with pneumatic ejector

Work area lighting

Signal light red / yellow / green

Parting tool breakage monitoring (speed monitoring)

Conversion kit between long and short turning

Coolant device

– a coolant pump 750 W

– movable jet arms

Part catcher

Swiveling parts catcher with conveyor belt to the right

Easy to switch to front or rear removal

interface

Interface for loading magazine

Power clamping system

Collet adapter type Schaublin 76-71 F22

Collet on main spindle 140E (Schlenker clamping tools)

Driven guide bush TF 26 Meister CH

99.001 new comm CH

Collet adapter type Schaublin 76-71 F22

Collet on counter spindle 140E (Schlenker clamping tools)

Collets and guide bushes are not included in the scope of delivery!

Tool holders and tools

1 tool box with set-up tools

Clamping pieces for tool holders (external machining)

coolant distribution pieces

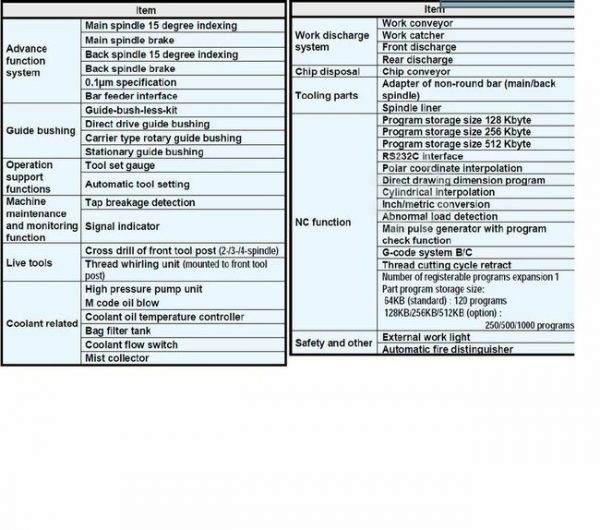

Special accessories

Execution variable as short or long turning EUR incl.

Counter spindle flushing including pneumatic ejector EUR incl.

Swiveling parts catcher with conveyor belt to the right EUR incl.

Chip conveyor to the right EUR incl.

3 driven tool holders on the front cross slide EUR incl.

C-axis on main and counter spindle EUR incl.

4 pieces (2 x transverse) driven tools on the back EUR incl.

C-axis on main and counter spindle EUR incl.

Pressure booster pump 16 bar including chip filtration

Tsugami B0126E-II – Year 2020