Description

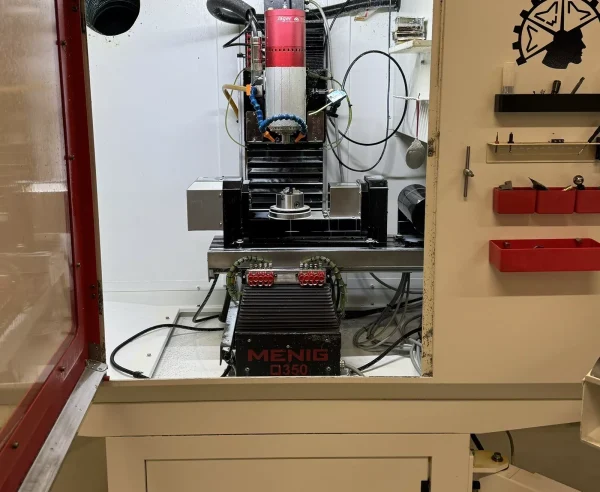

Menig Automation Q350 CNC Mill – Year 2019

Excellent for micro machining. 30,000 rpm spindle, automatic tool changer, simultaneous 5 axis machining. Machine body is solid granite for excellent rigidity and damping. Probing. Glass scales on linear axes. Harmonic drives for zero backlash on rotary axes.

Manufacturer Catalogue Information about Menig Automation Q350 CNC Mill for Micro Machining :

Q350 Specifications |

Metric |

Imperial |

Travel, X-axis |

490mm |

19.3" |

Travel, Y-axis |

300mm |

12" |

Travel, Z-axis |

300mm |

12" |

Spindle Nose to Table (~ max) |

377mm |

14.85" |

Spindle Nose to Table (~ min) |

47mm (optional 17mm) |

1.85" (optional .67") |

Table Dimensions |

L633mm x W 197mm |

L24.9" x W7.75" |

Number of T-slots |

3 |

|

Width of T-slot |

12mm |

7/16″ |

CNC Data |

Metric |

Standard |

Controller |

MotusCNC, Linux |

|

Servo Motor Resolution |

0.0002mm |

0.00001″ |

Axis Motor Type |

Brushless Servo |

|

Max Axis Speed X |

6350mm/min |

250ipm |

Max Axis Speed Y |

6350mm/min |

250ipm |

Max Axis Speed Z |

6350mm/min |

250ipm |

Machine Size and Weight |

Metric |

Standard |

Machine Dimensions: |

W 2073mm x D 942mm x H 1901mm |

W 81.6" x D 37.1" x H 74.8" |

Weight net |

600kg |

1320lbs |

Chopper Spindle Specifications |

||

Allowable Motor Speed |

5000-30000RPM |

|

Spindle Taper Accuracy |

<2μm |

<0.000079″ |

Spindle Power |

1.9kw |

2.6hp |

Standard Size Collet |

∅ 3mm, 6mm |

∅ 1/8″, 1/4″ |

Air Requirements |

113Liter/Min, 7Bar |

4CFM, 100PSI |

Power Requirements |

||

Power Input |

230VAC Single Phase 50-60Hz, (110V option available) |

Q350 CNC Mill

5,000-30,000 RPM German made Alfred Jaeger “Chopper” 1500D spindle with <2um runout or,

5,000-60,000 RPM 2.1kwm 5,000-60,000 RPM Alfred Jaeger Z62 Spindle

Optional 4th and 5th Axis Simultaneous Capable Hardware and Software

8 Tool Automatic Tool Changer with integrated Tool Height Setter

Intuitive MotusCNC™ Control Software. (Click link for more details)

Full Enclosure with Interior lighting

Optional Integrated Liquid Coolant system

Optional MQL (Minimum Quantity Lubrication) Cutting Tool Lubrication System

Optional XYZ Closed Loop Linear Scale System with (1 µm) resolution

Optional Integrated USB Camera

Optional High Precision Touch Probe

The Menig Automation Q350 CNC Mill offers an intuitive milling system with a

large work volume while providing the accuracy required for the most demanding applications. High rigidity in a small footprint is achieved by utilizing a granite

machine base that provides superior damping and thermal stability.

The Q350 features a maximized work area of 19.5 inches (490mm) in X-axis,

12 inches (300mm) in Y-axis and 12 inches (300mm) in Z-Axis travel. The

Q350 can be equipped with the 3.5Kw 5,000-30,000 RPM 1500D Alfred

Jaeger “Chopper” Spindle or the 2.1kwm 5,000-60,000 RPM Alfred Jaeger

Z62 Spindle. Both spindles utilize an 8-Tool Automated Tool Changer that allows

the user to achieve maximum job efficiency while not sacrificing surface quality

in plastics, metals and ceramic applications. MotusCNC™ Control Software

provides the user with a modern and user-friendly interface. Realtime visual

simulation and adherence to the Fanuc NC Standard allows easy integration

with any industry standard CAM software.

• Intuitive MotusCNC ™ Control Software

• Granite machine structure provides superior damping, thermal stability,

and superior accuracy

• 5,000-30,000RPM German made Alfred Jaeger “Chopper” 1500D

Spindle with <2um runout, or

• 5,000-60,000RPM German made Alfred Jaeger Z62 Spindle with <1um

runout

• 8 Tool Automatic Tool Changer with integrated Tool Height Setter

• Full Enclosure

• Optional Integrated Liquid Coolant system

• Optional XYZ Closed Loop Linear Scale System with (1µm) resolution

• Optional MQL (Minimum Quantity Lubrication) Cutting Tool Lubrication

System

• Optional Integrated USB Camera