Description

MITSUBISHI ML 3015 eX-F40 CNC Fiber Laser Machine 4kW – Year 2016

Technical specifications of the MITSUBISHI ML 3015 eX-F40 laser cutting machine

laser power: 4 kW

feed in X/Y/Z axis: 3100/1565/150 mm

maximum cutting thickness (plain steel): 25 mm

maximum cutting thickness (stainless steel) : 20 mm

maximum cutting thickness (aluminium): 15 mm

maximum cutting thickness (brass): 12 mm

maximum cutting thickness (copper): 6 mm

maximum workpiece dimensions (L x W): 3050 x 1025 mm

maximum workpiece weight: 950 kg

maximum travel speed: 100 m/min

simultaneous traverse speed of the X and Y axes: 140 m/min

positioning accuracy in the X,Y axis: 0.05/500 mm

positioning accuracy in Z axis: 0.1/100 mm

positioning repeatability in the X,Y axis: ± 0.01 mm

exchange table height: 880 mm

table exchange time: approx. 30 s

work head travel system: movable optics

wavelength: 1.07 μm

pulse frequency: 10-3000 Hz

pulse range: 0-100%

power control: 0-100%

laser resonator operating hours: 2750 h

technical gas pressure: 0.03-2.5 MPa

ambient temperature: 10-35 ± 5°C

connection power: 28 kVA

power supply: 3x 400 V; 50/60 Hz

machine dimensions with exchangeable table (L x W x H): 10340 x 3130 x 2250 mm

weight of interchangeable table: 2100 kg

weight of machine: 8900 kg

Equipment of the ML3015eX-F40(S2) laser cutting machine

CNC controller: MITSUBISHI M700

Zoom Head type cutting head with automatic focus

HPP function – high speed piercing function

MHC-L function – very fast and precise laser beam switching on and off

F-CUT function – fast cutting in interrupted straight lines using the MHC-L system, without the need to stop the head at the in and out points

FRG function – automatic cut path optimisation with F-CUT function

CAD/CAM software with NESTING: SigmaNEST

laser source: YLS-4000-ML

screw compressor: WALTER

pillar jib crane: PROMAG 1000 KG

sheet metal vacuum lifter

lenses 5″ and 8″

servomotors in the X and Y axes

ball screw in Z axis

chiller: OMEGA technotrans

TEKA filter

exhaust extraction system with swing flap system

barcode scanner

3 technical gas connection points (O2, N2, air)

fully automatic glass door

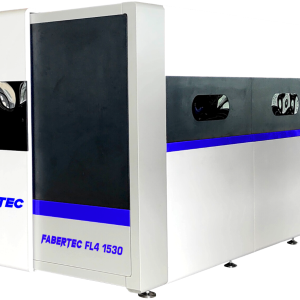

MITSUBISHI ML 3015 eX-F40 4 kW fibre laser built in 2016 in Japan is used in precision machining of various types of sheet metal. The extremely technically advanced machine uses the most advanced technology available on the market, including an energy-efficient and trouble-free laser source with the highest energy output, which feeds the cutting head with a 4 kW fibre optic beam. The magnetically mounted Zoom Head type head additionally optimises cutting parameters automatically according to material thickness and reduces the effects of collisions.

The structure, based on a high-quality casting, is designed for maximum user comfort. The large working area is covered by an all-glass, automatically rising door, while the resonator and all electrical systems are integrated into the machine frame. In addition, in the case of failure in one of the diode modules, a power reserve allows the machine to continue operating at nominal performance.

The MITSUBISHI fibre laser is offered with the necessary systems and equipment to fully automate the machining process. This includes a 1000 KG pillar jib crane with sheet metal vacuum lifter and CAD/CAM software with NESTING function, which arranges 2D parts in such a way as to best save space on a machined workpiece. The MITSUBISHI ML3015 eX-F 40 fibre laser cutting machine weighs 8900 kg.