26/07/2024

What is Precitech Nanoform X Small Frame SPDT Single Point Diamond Turning Lathe?

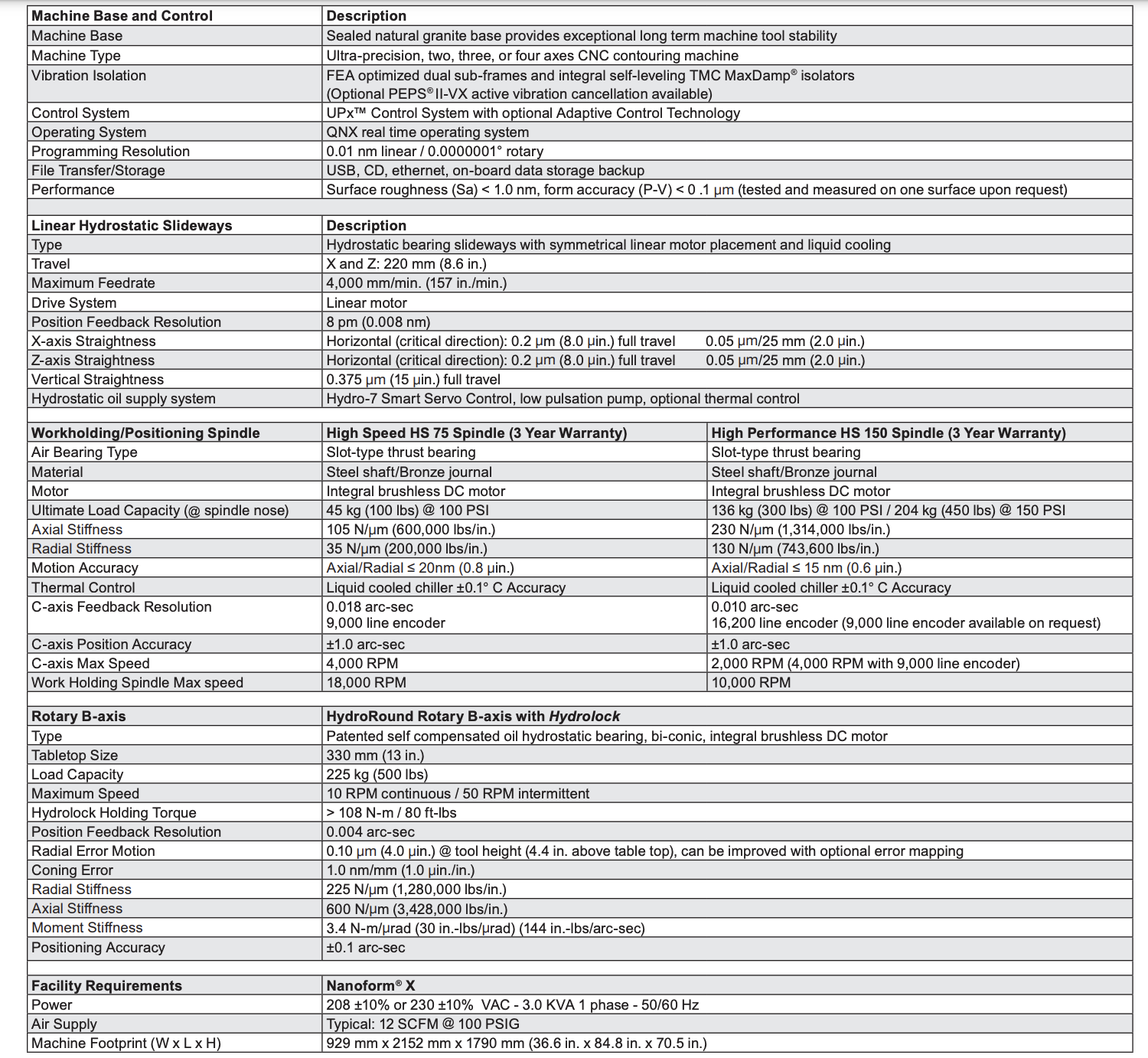

The Precitech Nanoform X Small Frame SPDT (Single Point Diamond Turning) Lathe is a highly specialized machine tool designed for ultra-precision machining. Here’s a technical breakdown of its components and functionalities:

1. Single Point Diamond Turning (SPDT)

- SPDT: This machining process involves using a single cutting tool, typically a diamond, to create highly precise and smooth surfaces on a workpiece. The diamond tool has a very sharp edge, enabling it to cut at the nanometer scale.

2. Machine Frame and Structure

- Small Frame: Refers to the compact and rigid design of the lathe, which is crucial for minimizing vibrations and maintaining stability during the machining process. This is essential for achieving high precision and accuracy.

- Material and Construction: The frame is often made from materials with high thermal stability and low vibration characteristics, such as granite or specialized alloys, to ensure minimal thermal expansion and mechanical distortion.

3. Precision Motion Control

- Linear and Rotary Axes: The Nanoform X typically features high-precision linear stages for X, Y, and Z movements, along with rotary stages for angular positioning. These stages are driven by advanced servo motors or piezoelectric actuators.

- Feedback Systems: High-resolution optical encoders or laser interferometers provide feedback to the control system, ensuring precise positioning with nanometer or sub-nanometer accuracy.

4. Spindle System

- Ultra-Precision Spindle: The spindle system is designed to rotate the workpiece with extremely low runout (typically in the sub-micrometer range) and minimal thermal drift. This is crucial for maintaining the integrity of the machined surface.

- Air Bearings: Often utilizes air bearings for both the spindle and the linear stages, which provide frictionless motion, enhancing precision and reducing wear.

5. Control System

- CNC Controller: The machine is equipped with a sophisticated CNC (Computer Numerical Control) system that coordinates the movements of the tool and the workpiece. It processes complex machining instructions and ensures synchronized operation of all axes.

- User Interface: Advanced software interfaces allow operators to program intricate geometries and fine-tune machining parameters with high precision.

6. Tooling and Workpiece Handling

- Diamond Cutting Tool: The primary cutting tool is a diamond, selected for its extreme hardness and sharpness. The tool must be precisely oriented and maintained to achieve the desired surface finish.

- Workpiece Fixturing: The machine includes high-precision chucks or vacuum systems to securely hold the workpiece without introducing distortions.

7. Environmental Control

- Temperature Control: The machine environment is often tightly controlled to maintain consistent temperature, as even small thermal variations can affect precision.

- Vibration Isolation: The lathe is typically mounted on vibration-damping platforms or housed in rooms with controlled vibration levels to avoid external disturbances.

8. Applications

- Optics: Used extensively in the production of optical components such as lenses, mirrors, and other elements requiring extremely smooth and precise surfaces.

- Aerospace and Defense: Manufacturing high-precision components that demand stringent tolerances and surface finishes.

- Medical Devices: Producing intricate and precise parts for medical applications.

The Precitech Nanoform X Small Frame SPDT Lathe is a sophisticated piece of equipment designed for the highest levels of precision machining, capable of producing surfaces with nanometer-level accuracy and smoothness.