Why do Customers prefer using INDEX B400 CNC Turning Center Machine?

The INDEX B400 CNC Turning Center Machine is highly regarded in the industry for several technical reasons. Here are some of the key features and benefits that make it a preferred choice among customers:

1. Precision and Accuracy

- High-Precision Components: The INDEX B400 is equipped with high-precision spindles and ball screws, ensuring tight tolerances and exceptional accuracy in machining.

- Thermal Stability: The machine incorporates advanced thermal management systems to minimize thermal distortion, maintaining consistent precision even during extended operations.

2. Versatility and Flexibility

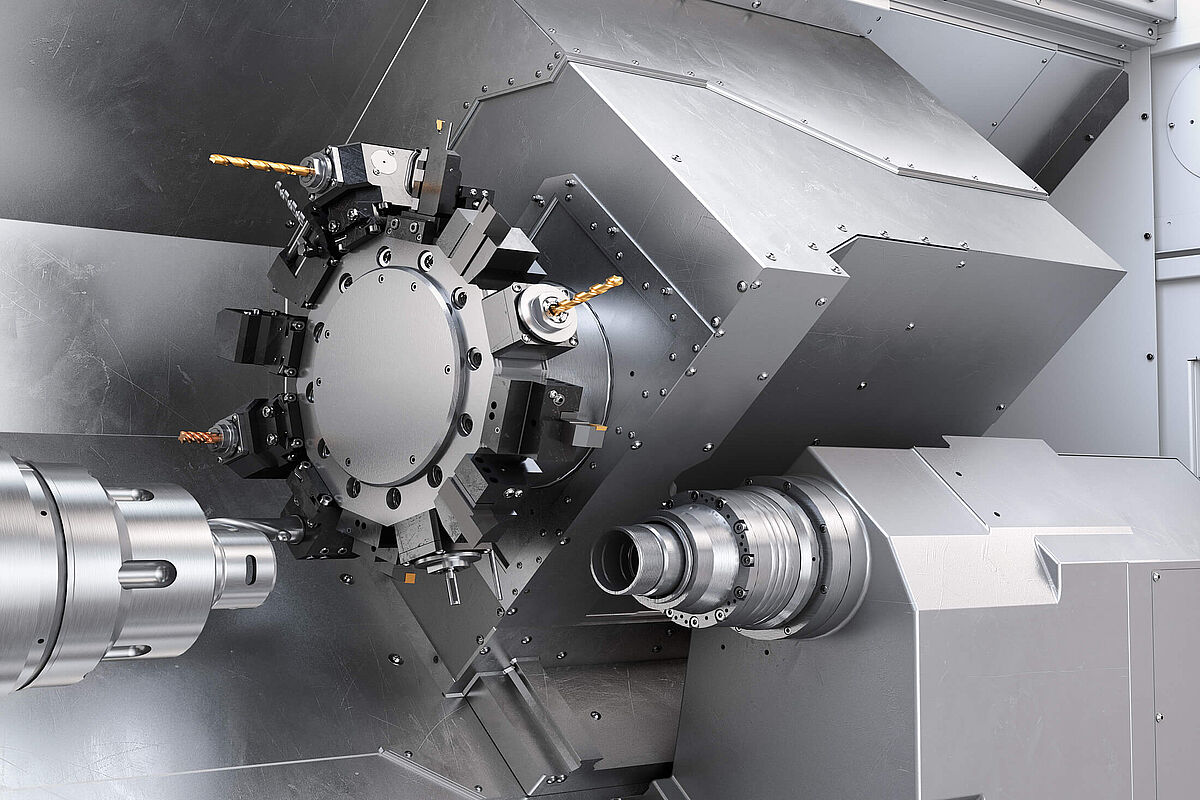

- Multi-Axis Capability: The B400 offers multi-axis machining, allowing for complex geometries and intricate part designs to be machined in a single setup. This reduces the need for multiple machines and setups, saving time and improving efficiency.

- Tool Turret: Equipped with a robust tool turret that can hold multiple tools, enabling quick tool changes and reducing downtime.

3. High-Speed Performance

- Rapid Traverse Rates: The machine boasts high rapid traverse rates, reducing non-cutting time and increasing overall productivity.

- High Spindle Speeds: Capable of achieving high spindle speeds, the B400 can efficiently handle a variety of materials, from soft aluminum to tough stainless steel, improving cycle times.

4. Advanced Control System

- CNC Control: The INDEX B400 is integrated with advanced CNC control systems (such as Siemens or Fanuc), offering user-friendly interfaces, high processing power, and advanced programming capabilities.

- Adaptive Control: The machine features adaptive control technology, which automatically adjusts cutting parameters in real-time to optimize performance and extend tool life.

5. Rigidity and Stability

- Robust Construction: The B400 is designed with a heavy-duty cast iron base and sturdy construction, providing excellent rigidity and stability. This minimizes vibrations and enhances machining accuracy.

- Advanced Damping Systems: Integrated damping systems reduce the impact of vibrations, further improving the surface finish and prolonging the life of both the machine and tools.

6. Automation and Integration

- Automation Options: The machine can be equipped with various automation solutions, such as robotic loading/unloading systems, bar feeders, and part catchers. This enables unattended machining and higher throughput.

- Industry 4.0 Ready: The B400 is compatible with Industry 4.0 technologies, allowing for seamless integration into smart factory environments. It supports remote monitoring, predictive maintenance, and data analytics for improved operational efficiency.

7. Ease of Maintenance

- Modular Design: The modular design of the INDEX B400 simplifies maintenance and repairs, ensuring minimal downtime and easy access to critical components.

- Diagnostic Systems: Built-in diagnostic systems provide real-time monitoring of machine health, alerting operators to potential issues before they become critical.

8. Energy Efficiency

- Energy-Saving Features: The B400 includes energy-saving features such as regenerative braking and efficient power management systems, reducing operational costs and environmental impact.

9. Customer Support and Service

- Comprehensive Support: INDEX offers robust customer support and service options, including training, preventive maintenance programs, and quick-response technical assistance.

Conclusion

The INDEX B400 CNC Turning Center Machine is preferred by customers due to its combination of precision, versatility, speed, advanced control systems, rigidity, automation capabilities, ease of maintenance, energy efficiency, and strong customer support. These technical features enable manufacturers to achieve high-quality machining results, reduce operational costs, and enhance overall productivity.