Description

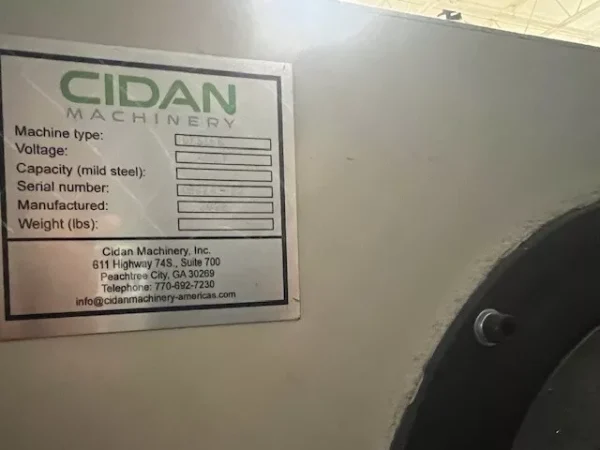

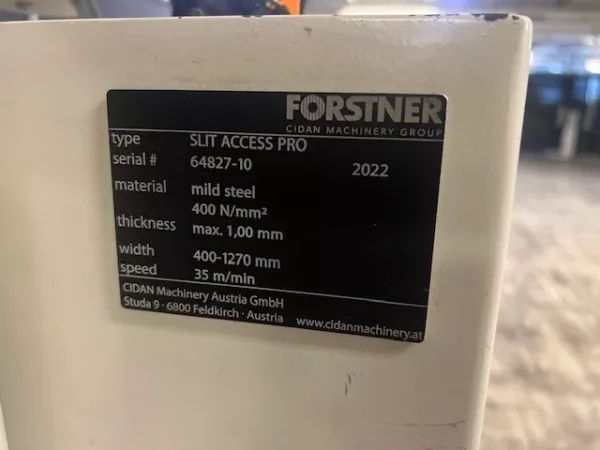

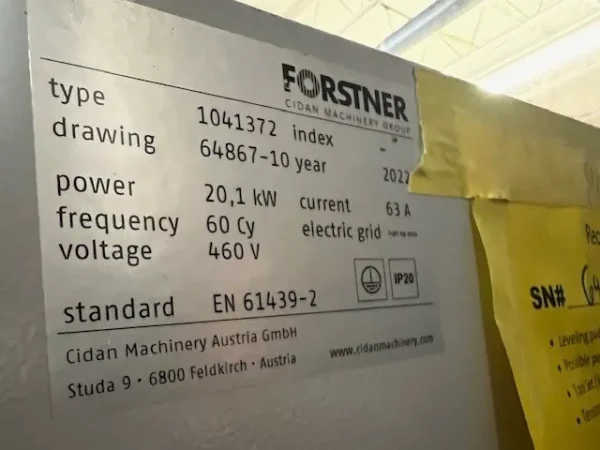

Cidan Machinery Forstner nuSLIT Pro Cut-to-Length Line – Year 2022

2022-2023 Cidan Machinery Forstner Nu-Slit Pro slitting line for sale in mint condition. Seen running 26 ga mill finish coil.

Type: Automatic Slitting and Cut-to-Length

Working Width: 50″ (1250 mm)

Slitting Capacity – Steel: 20 ga

Slitting Capacity – Stainless: 24 ga

Slitting Shaft: 4.17″

Slitting Knives: 5 pairs

Speed: 25 m/min

Shear: Guillotine

The slitting line was purchased new from Cidan Machinery in December 2022 and was installed in May 2023. It has been under power and in production since that time. We need to sell this one to make room for new equipment.

The full list of equipment is below:

QXS16C 16,000lb. Powered Decoiler with coil cart 20″ hydraulic mandrel with remote

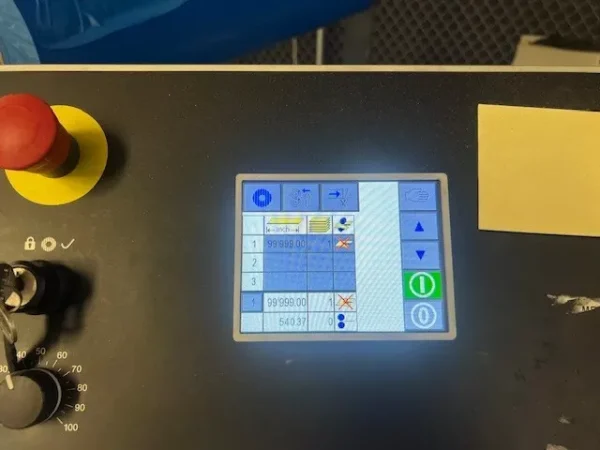

Slit Pro 1250 50” wide, Slit and cut-to-length with infeed roller guide & table, and F3 control

Access Table 48” – Enable operator access to slit blades without moving material table

High Speed of 115FPM, in lieu of standard 85FPM

Radio Control for switching decoiler into automatic mode via the slitter control

RC5 1250 Recoiler, Tension stand and coil cart, 11,000lb. capacity, 5 slits of 20ga

High Speed Motor 115FPM in lieu of standard 85FPM

Power: 460-480V 3 Phase

Options:

Radio Control for switching decoiler into automatic mode via the slitter control

Remote control jog pendant- 1 person setup on the decoiler, slitter and recoiler

Radio Control for switching recoiler into automatic mode via the slitter control

AL1250M Rotary Cross-Cut, manual, mounted after tensioner. Enables quick change of small coils and not have to refeed thru tensioner.

CC1205 coil cart for Recoiler

Film Applicator

Scrap winder with dancer arm

The sllitting line is currently under power and in use. Available for inspection and demonstration at any time on weekdays.

Can’t fit everything into your schedule? nuSLIT Series + nuIT will fix it for you.

FORSTNER nuSLIT is the machine

every modern sheet metal

workshop dreams of. With the

nuSLIT module cut-to-length line

you just set the slitting width, length and quantity on the

control panel and press start. The machine then straightens

your material and your sheets are ejected with amazing

precision, with no stop marks and ready for the next step in

production. nuSLIT is the cut-to-length machine that brings

you higher quality and greater productivity with no manual

adjustments.

New opportunities with worldwide innovation

Make your production easier than ever! With a combination

of FORSTNER nuSLIT and nuIT’s software, you end up in a

whole new world. nuIT is the system that gives you a fully

integrated process from order to finished profile.

nuIT revolutionizes your entire manufacturing process

Let your customers or coworkers in the field, office or factory

floor design their profiles or choose ready-made ones from a

library. All you need is a mobile device, tablet or laptop where

you can draw your profiles. Once your customer has finished,

the data becomes a production order that you can schedule

and submit into production. Send the production order

containing all the data directly to your nuSLIT machine with

PROCUT option, and the system automatically calculates how

to best cut the material without wastage or risk of human

The most important advantages:

✔ All orders are handled automatically

✔ Maximum flexibility for order handling

✔ No risk of human error

✔ Optimal material utilization

✔ Extensive time savings

✔ Total control

The material is fed into the machine and is ejected as

finished cut pieces of varying lengths according to your

choice.

Total control from order to invoice

Equip your nuSLIT machine with an integrated label printer

and your finished pieces will have barcodes with all the

necessary data for the next step in production. Your folder

has already received all the data for folding the panels and

will now read the QR codes to automatically set the correct

values for your profile. With nuIT no programming is needed.

You are in full control, from calculations, material consumption

and resource planning to QR codes, production, delivery

feedback to the system and invoicing. Busy and complex

working days spent multitasking in your sheet metal

workshop are now child’s play!