09/01/2025

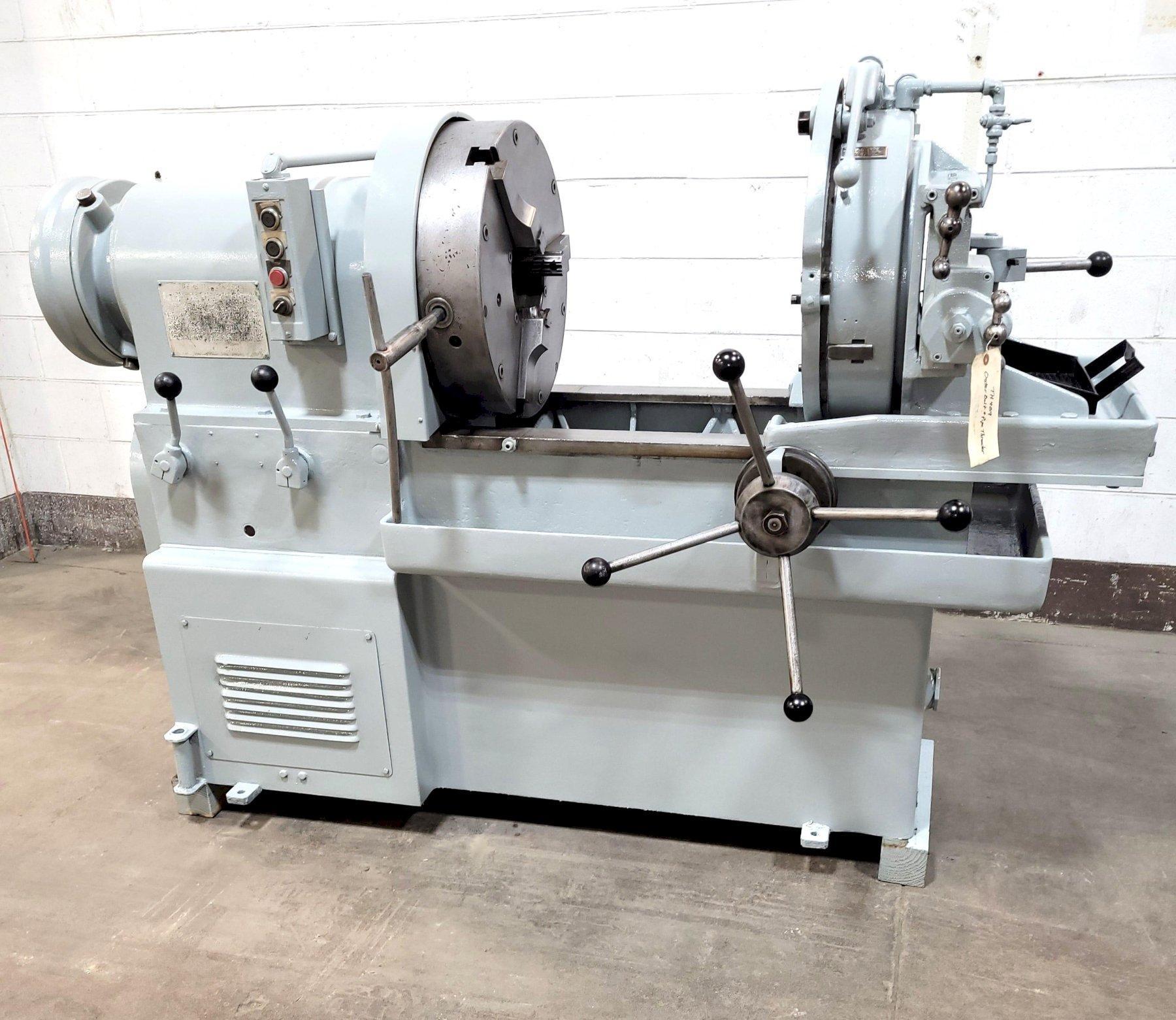

What is Pipe and Bolt Threading Machine?

A Pipe and Bolt Threading Machine is a specialized mechanical tool designed to cut precise threads onto the ends of pipes and bolts, enabling them to fit securely into threaded fittings or nuts. It is commonly used in industries like plumbing, construction, and manufacturing where threaded connections are required for assembly or fluid transport systems. Here’s a technical breakdown:

Key Components

- Threading Dies

- Replaceable cutting tools made from hardened steel, shaped to form specific thread profiles (e.g., NPT, BSPT for pipes; UNC, UNF for bolts).

- Chuck and Clamp Mechanism

- Holds the pipe or bolt securely during threading, preventing slippage.

- Electric or Manual Drive System

- Electric models use a motor for automated threading, offering consistent speed and torque.

- Manual models rely on hand-cranked or lever-driven systems for smaller-scale operations.

- Gearbox

- Reduces motor speed to the appropriate threading speed, ensuring precision and smooth operation.

- Cutting Oil System

- Provides lubrication to the threading dies, reducing friction, dissipating heat, and prolonging tool life.

- Thread Gauge and Calibration Tools

- Ensures the cut threads meet dimensional accuracy and tolerance standards.

Technical Functionality

- Setup and Clamping

- The pipe or bolt is inserted into the machine and clamped securely using the chuck. Proper alignment is critical to ensure uniform threading.

- Thread Cutting

- The machine advances the die head onto the workpiece, cutting threads as it rotates.

- Thread depth and pitch are controlled by the die and feed mechanism.

- Lubrication

- Continuous application of cutting oil ensures clean cuts and prevents the dies from overheating.

- Reversing and Finishing

- After threading is complete, the machine retracts the die head, and the workpiece is removed.

Technical Features

- Threading Capacity

- Defines the range of pipe or bolt diameters that can be threaded (e.g., 1/8” to 6” for pipes).

- Threading Speed

- Measured in rotations per minute (RPM), often adjustable to accommodate different materials.

- Thread Standards Supported

- Examples:

- Pipe Threads: NPT (National Pipe Tapered), BSPT (British Standard Pipe Tapered)

- Bolt Threads: UNC (Unified Coarse), UNF (Unified Fine)

- Examples:

- Portability and Weight

- Machines range from lightweight portable models for fieldwork to heavy-duty stationary models for workshop use.

- Material Compatibility

- Suitable for threading various materials like steel, stainless steel, brass, copper, and PVC (with appropriate dies).

Applications

- Pipe Threading

- Used in plumbing and gas pipelines for secure, leak-proof connections.

- Bolt Threading

- Critical in manufacturing industries to produce threaded bolts for assemblies.

- Repair and Maintenance

- Useful for re-threading damaged threads or creating threads on-site.

- Fabrication Shops

- Integral for custom piping and structural components.

Advantages

- High precision and repeatability.

- Saves time compared to manual threading methods.

- Supports multiple thread standards and sizes.

- Durable and capable of handling heavy workloads.