Description

| Turning Ø | 200 mm |

|---|---|

| Ø above the bed | 90 mm |

| Ø above transversing slide | 160 mm |

| Length between centers | 400 mm |

| Type of CNC | SIEMENS Sinumerik |

| Max workpiece weight | 30 kg |

| Spindle bore | 55 mm |

| Number of turrets | 1 |

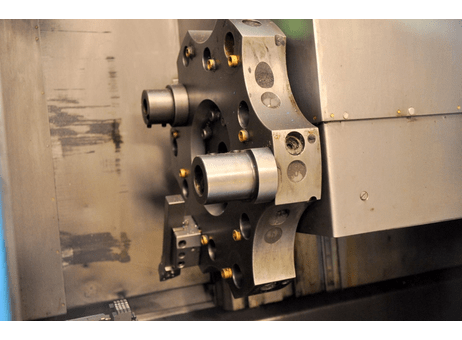

| Number of tools on turret | 12 |

| Turning speed | 8000 rpm |

| Spindle motor power | 11 kW |

| Tailstock | yes |

| Bar feeder | no |

| Length x width x height | 2585.0 × 1840.0 × 1855.0 |

| Weight | 4200 kg |

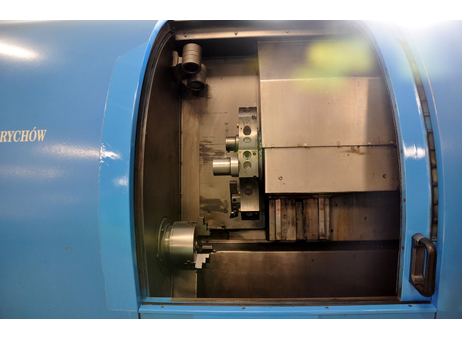

AFM ANDRYCHÓW TAE 30 N automatic lathe was produced in Poland by Andrychowska Fabryka Maszyn in 2002. The CNC lathe is equipped with a control from the renowned SIEMENS brand. The machine has a coolant tank, a steering pedal and an Operation and Maintenance Manual. The price of the machine includes: cooling system, basket for details, interchangeable jaws for the handle and operation and maintenance manual.

Technical data of the TAE 30 N CNC lathe

– CNC control: SIEMENS SINUMERIK

– maximum diameter of the material processed in the holder: 200 mm

– nominal revolutions: 1500 rpm.

– maximum revolutions: 8000 rpm.

– turning length in centers: 400 mm

– diameter of the hole in the spindle: 55 mm

– spindle diameter under the front bearing: 90 mm

– working path of the cross slide: 160 mm

– working path of the longitudinal support: 400 mm

– speed control: stepless

– maximum weight of the processed detail in the holder: 30 kg

– torque on the spindle at nominal speed: 101 Nm

– instantaneous moment (20 sec) at nominal revolutions: 143 Nm

– lift of the spindle axis over the bed guides: 259 mm

– passage diameter over the bed covers: 500 mm

– diameter of the passage over the guides of the cross slide: 340 mm

– number of spindles: 1

– number of tools in the head: 12

– spindle nose: 140 mm

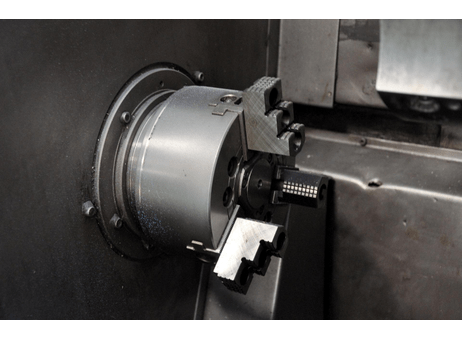

– cone in the tailstock: Morse 4B

– quill extension: 63 mm

– clamping force of the canine: 70-800 daN

– main drive: AC motor with stepless speed control

– main drive power at nominal speed: 11 kW

– spindle speed range: 50-5000 rpm.

– rotation correction in relation to the programmed: 50-120%

– the range of the speed of working feeds in the X axis: 0-15,000 mm / min.

– range of working feed rates in the Z axis: 0-20,000 mm / min.

– maximum speed of rapid movements in the X axis: 15 m / min.

– maximum speed of rapid movements in the Z axis: 20 m / min.

– dimensions (length x width x height): 2585 x 1840 x 1855 mm

– weight of the TAE 30N CNC lathe: 4200 kg

Machine characteristics:

It is a chuck and center lathe, which is a universal numerically controlled two-axis lathe with a turret. The machine is designed for processing the material mounted in the centers, the handle and is used for processing from the bar feeder.

The machine is characterized by the stiffness of the bed, slides and turret head, which allows the execution of even very complex tasks with excessive cutting parameters, using modern cutting tools. The lathe is equipped with a turret with rotary tools, with axes parallel or perpendicular to the spindle axis, which additionally allow performing operations such as drilling, longitudinal and transverse milling with the spindle stopped.

The lathe spindle has the option of angular positioning, thanks to which it can perform operations with rotary tools many times, at any angle. When machining objects mounted in centers, for one clamping, you can perform such types of machining as: face planing, multi-stage cylindrical turning with cutting grooves or grinding recesses, spherical surface turning, turning conical surfaces, turning right or left threads, cylindrical or conical one and multi-income.

On the other hand, when machining objects mounted in the holder, for one clamping, you can perform all procedures as in external turning, but also such types of machining in the hole as: drilling holes – even with very small diameters, using the summation of the spindle revolutions and the counter-rotating tool in the head turret, reaming, boring cylindrical surfaces, cutting grooves and grinding recesses, boring spherical surfaces, threading with a tap, turning right or left threads, cylindrical or conical, single or multi-threaded. Spindle revolutions are steplessly regulated in the range from 50 to 5000 rpm, which allows for the selection of the best cutting parameters.