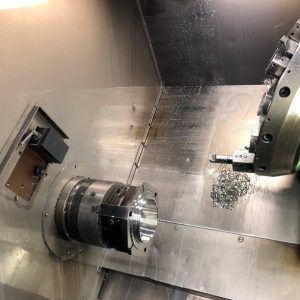

Description

Spinner TC 800 110 L-MCY – Year 2018

Control Siemens 840DE with flat colour screen 15″

turning spindle up to 2nd axis 600 rpm;

power 28/35 KW,

torque 175 / 875Nm intake DIN55026/A11 2-step gear for spindle,

automatically switchable in the program Drive motors for X/Z and spindle in digital AC technology

Travels X=360mm Z=1580mm Y=-55/+65 mm Fully integrated into the machine structure Y-axis by inclined slide C-axis for spindle including software option “Transmit” for face machining and “cylinder interpolation” for jacket machining C-axis with drive of the spindle in milling mode by separate gear motor Hydraulic hollow clamping cylinder, Clear width in the draw tube 110 mm (bar passage) 12-fold indexing turret for tool holder according to DIN69880/50mm, AC-Servo,

Baruffaldi system, RADIAL REceptacle 12 driven tool stations in the indexing turret for milling and drilling operations Electrical interface for connection of bar feeds according to SPINNER-UNIMAG standard Splash guard full enclosure + coolant unit + work area light + hydraulics Required set-up elements on the machine bed for vibration damping and adjustment Documentation: SPINNER manual and Siemens manuals digital on CD Painting two-colour RAL 7035/5008

Tailstock for TC800, MK4

Tailstock base body in the program can be automatically coupled and trailed to the Z-axis, hydraulically clamped with foot switch for forward/backward

149232 Chip conveyor for TC800-L standard version mounted in machine base.