Description

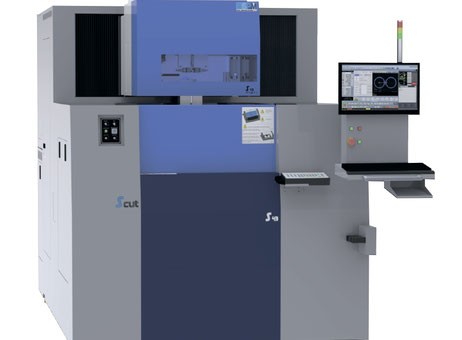

SPM S43 CNC EDM Wire – Year 2019

| X Axis | 400 mm |

|---|---|

| Y Axis | 300 mm |

| Z Axis | 250 mm |

| Max. workpiece length | 700 mm |

| Max. workpiece width | 500 mm |

| Max. workpiece weight | 400 kg |

| CNC Type | SPM |

| Worktank length | 856 mm |

| Worktank width | 770 mm |

| Worktank height | 250 mm |

| Max. workpiece height | 240 mm |

| Automatic Wire Feeding | Yes |

| Length x width x height | 1641.0 × 2426.0 × 2150.0 |

| Weight | 2570 kg |

| Worked hours | 0 hours |

| Hours under power | 0 hours |

| State | new |

Amount of movement

X mm 400

Y mm 300

Z mm 250

U mm 100

V mm 100

Speed of fast moving x m / min 1300

Y m / min 1300

Z m / min 1300

U m / min 1300

V m / min 1300

Maximum machining angle with standard guide dies

deg / mm ± 24/100

Maximum machining angle with special guide dies deg / mm ± 45/50

Accuracy parameters

Discretization of movements in all axes mm 0.0001

Positioning accuracy mm ± 0,002

Work Area Settings

Internal dimensions of the working bath (LxW) mm 856 х770

Width of the doorway of the working bath mm 768

Sizes of a desktop of mm 664х470

The maximum dimensions of the workpiece (LxWxH) mm 700x500x240

Maximum billet weight kg 400

Height from floor to table surface mm 1000

Processing parameters

The main processed material Tool steel

Surface roughness (Ra) on an area of mm2 – 2-3 passes µm 0.4

The best surface roughness (Ra) on an area of mm2 – 4 passes µm 0.17 -0.18

Maximum performance (workpiece height 50mm Cr12 material electrode-wire 0.25 mm) mm2 / min 300

Tool parameters

Electrode Type – Wire Tool

Wire diameter min mm 0.15 max mm 0.3

Maximum mass of an electrode tool kg 10

Used coil type P5, K160, P10

Wire feed speed m / min 0-15

Wire tension H 0.5-28

Automatic dressing device and wire cutter – Availability

CNC device parameters

CNC device

SPM

Input method USB flash memory, CD-ROM, LAN, MDI

Monitor 20 “, LCD

Input language RUSSIAN, Korean, English, Italian, French, Chinese, Turkish, Japanese, Slovene, German

Full closed loop control method (B axis option)

The controlled axes 5 simultaneously controlled axes + the possibility of up to 3 additional axes in the mode of positioning axes

Minimum software movement value mm 0.0001

Max. programmed displacement value mm ± 9999.999

Command format relative / absolute

Interpolation functions Linear, circular and spiral

The minimum and maximum input value is 0.001 ~ 9999.999 mm

Adaptive feed control Automatic change of feed rate, depending on the distance between the electrode and the workpiece

Wire movement control Electrode removal from the workpiece along the cut path

Graphic 2D / 3D graphic display of the workpiece position and movement of the processing, in real time

The maximum input value is E-pack 9999

Maximum number of E-pack 9999 programs

Basic processing menu Automatic control;

Manual control;

NC data, etc.

Maintenance function Consumables wear monitoring system, displaying messages about the need for replacement

Record System Status To Hard Disk or to External Media

System Autotech Preinstalled, with the ability to edit

Operating impulse generation system With the help of modern MOS transistors

Short-circuit protection Automatic, permanent

EzSharp + sharp angle cutting system (Automatic wire offset for cutting sharp corners, improving the quality of processing sharp edges)

System of protection against accelerated corrosion of the workpiece during the processing of EzAqua + (Protection of the workpiece against corrosion, protection against changing the color of the workpiece, eliminating the need for grinding the surface after processing)

Precision Cone Cutting System EzTaper + (Independent movement of the U and V axes, inclination of the wire up to 45 °, easy adjustment of the tapered cut)

Turntable Optional

System of remote monitoring of machine condition and control Pre-installed, unlimited number of workplaces

Remote Control Full Function

Splash Protection System during Wire Filling and Processing Pre-installed

The parameters of the system of preparation and cleaning of the working fluid

Working fluid

deionized water

Working volume l 620

Bulk capacity for ion exchange resin l 15

The degree of filtration of the working fluid μm 5-10

Number of filters pcs 4

Automatic control system of the specific conductance of the working fluid

Generator parameters

Maximum operating current A 45

Hz current frequency 50 ± 1

Voltage 220

Maximum power consumption kW 10

Water cooling electrical cabinet

closed

Electrical connection parameters

Power supply Phase number pcs 3

voltage 220

Hz frequency 50 ± 1

Electric input power kW 20

Compressed air connection parameters

Air pressure atm 5

Air consumption l / min 80

Mass-dimensional parameters

Overall dimensions of the machine, taking into account the service area

length mm 2753

width mm 3605

height mm 2150

Weight kg 2570