Description

| Max. grinding length | 200 mm |

| Grinding diameter | 400 mm |

| Exter | Yes |

| Inter | No |

| CNC | Yes |

| STUDER S20-2 – 2007 Model | |

| Max. swing diameter | 199 mm |

| Max. height from spindle to table | 100 mm |

| Max. wheel speed | 1200 rpm |

| Spindle motor power | 3 kW |

| Cylindrical external / internal grinding machine | |

| Worked hours | 15000 hours |

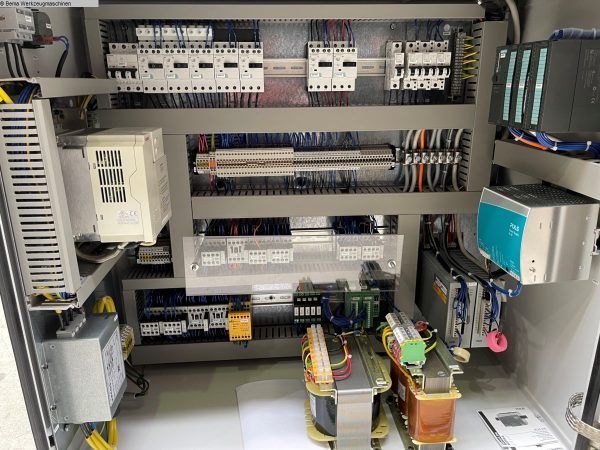

TECHNICAL DETAILS

grinding diameter 200 mm

grinding length 400 mm

center height 100 mm

VIDEOS

No video files available

ADDITIONAL INFORMATION

Machine with 15.000 hours of operation.

Before delivery x-axis and z-axis are

completely dismantled:

– Disassembly and cleaning of the machine

– Preparation of all parts to be painted

– Scraping of the z-axis machine bed and lower table if required

– Checking Schneeberger guides and replacing them if necessary

– Overgrinding of the upper table

– Scraping / overgrinding of the upper side of the upper table

– Reworking of all turning and contact surfaces

– Grinding of the taper on the work headstock if required

– Adjustment of the machine geometry according to Studer measuring protocol.

– Replacement of wear parts such as switches, probes,

oil sight glasses, seals, etc.

Work headstock:

– Cleaning of the spindle housing

– Disassembly ,cleaning and inspection of the grinding spindle

– Installation of the grinding spindle

– Grinding or scraping of all rotating and contact surfaces

– Cone grinding if required

– Parallelism of workpiece spindle to table horizontally and vertically according to

Measurement protocol

Replacement:

– the carriage bearings

– all seals

– the drive belts

workpiece spindle motor:

– overhaul of the motor

– renewal of the cable

– Painting

Tailstock with fine adjustment:

– Checking or renewal of the tailstock quill.

– Inspection of the guide bushes and ball cages. If necessary

Renewal.

– Renewal of the seals

– If necessary, adapt the new quill to the new sleeve

– Dismantle fine adjustment and renew if necessary (if

available)

Grinding spindle motor:

– Checking the motor

– Renew the bearing

Grinding spindle head:

– Cleaning of the spindle housing

– Disassembly ,cleaning and inspection of the grinding spindle

– Installation of the grinding spindle

– Replacing the drive belts

– Renewing the water supply

Lubrication:

– Renew lubrication lines

Feed spindle:

-Renew spindle only if necessary

-Renew the axial bearing

Z-axis:

-Renew or rework the recirculating ball screw

X-axis:

– renewal of the Schneeberger guides

– grinding or scraping of the slide

– reworking of the coarse adjustment on distance plates

Grinding headstock and internal grinding device

table reversal:

– Renewal of bearings

– Renewal of the O-ring

Painting in new machine quality:

z-axis lower table up

x-axis slide and superstructure