Description

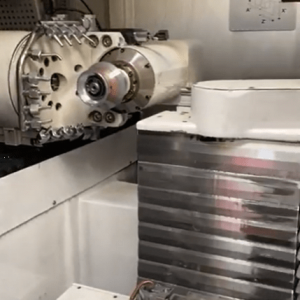

Lakfam ASP-631F SL5 – Year 2016

| CNC 5 Axis Tool Grinding Machine | |

| Max. longitudinal travel | 370 mm |

| Cross travel | 350 mm |

| Max. height from spindle to table | 340 mm |

| Wheel diameter | 150 mm |

| Hydraulic motor | 1.1 kW |

| Lakfam ASP-631F SL5 | |

| Length x width x height | 1530.0 × 1480.0 × 1910.0 |

| Weight | 800 kg |

A five-axis CNC grinder enables sharpening of:

– front surface along and across the tool rotation axis (horizontal or vertical movement of the grinding wheel) – lateral surface along a helix and with different pitch of individual blades

– rake face

– contact area

– two-phase relief surface

Types of topping:

– linear

– angular

Sharpening can be done in two ways:

– no bounce

– with bounce (return at maximum speed).

Work cycles:

– one trim per revolution of the tool

– all adjustments per tool revolution

Equipment of the LAKFAM ASP-631 F-SL5 CNC tool grinding machine

– Renishaw TS27R contact probe

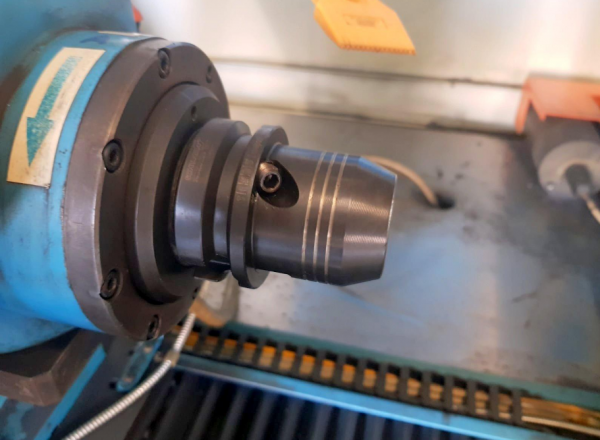

– hydraulic clamping holder TENDO ECompact MASBT40

– 5-20 collet set

Technical data of the LAKFAM ASP-631 F SL5 tool sharpener

– 5 programmable axes

– 5 axes interpolated simultaneously

– grinding wheel drive motor power: 1.1 kW

– grinding wheel diameter: max 150 mm

– spindle for 2 grinding wheels

– grinding wheel mounting diameter: 20 mm

– diameter of the sharpened cutter: max 160 mm

– angle of rotation of the divider A: any

– angle of rotation of the grinding wheel in the vertical plane B: any

– dividing head inner cone: BT40

– max weight of the sharpened tool: 10 kg

– longitudinal travel X: 370 mm

– cross travel Z: 350 mm

– vertical travel Y: 340 mm

– working feed speed: 0.2-2 m / min

– total weight: 800 kg

AKFAM ASP-631F SL5 CNC tool grinder was built in 2016 by the LAKFAM KOWARY company in Poland. It was created for the purpose of automatic sharpening of rotary tools made along a helical line. The machine has a CNC control, which provides work in 5 axes in an automatic cycle, without the need to manually move the grinding head. In addition, it allows you to sharpen objects with shaped and oval surfaces. The grinder allows you to process an object with a maximum weight of 10 kg and a diameter of up to 160 mm. In turn, the X, Y, Z axis shifts are 370 mm, 340 mm and 350 mm, respectively.

The machine has a Renishaw TS27R contact probe, which allows you to determine parameters such as pitch, diameter and position angles in a simple and extremely precise way. Moreover, the tool grinder is equipped with a hydraulic TENDO E Compact MASBT40 clamping holder, which significantly increases the tool life, improves the accuracy and stability of the dimensioning process.

Description of the work of the 5-axis tool grinder Lakfam ASP-631 F-SL5

Numerical control is equipped with the memory of the characteristic parameters of 500 cutters and the memory of all parameters of the last work cycle. The helix is determined by entering its pitch, or by reading the actual pitch directly from the sharpened tool – using the measuring probe. The longitudinal carriage as well as the stand with the grinding spindle operate on linear guides.

Both shifts are controlled automatically, which enables the tooth to be sharpened to the desired depth with linear dressing. The ASP-631F SL5 tool grinder has drives with DC motors, and the control is carried out using a controller with easy and accessible programming, with which you can program information characterizing the sharpening process.