Description

| Axis X | 15500 mm |

| Axis Y | 4000 mm |

| Axis Z | 2500 mm |

| CNC | FANUC 31i-B5 |

| Number of tool pockets | 16 |

| Spindle taper | HSK63A |

| Max. spindle speed | 10600 rpm |

| Spindle motor power | 20 kW |

| CMS Concept 40/155/25 PX5 | |

| Length x width x height | 21000.0 × 9500.0 × 7500.0 |

Technical data of the CMS Concept 40/155/25 PX5 high-speed 5-axis milling center

– 5 axes (X,Y,Z,C,A)

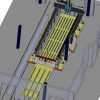

– jumps in the X/Y/Z axes: 15500/4000/2500 mm

– jumps in the rotary axes C/A: ±300/±110°

– speed of quick positioning in the X/Y/Z axes: 85/85/45 m/min

– speed of quick positioning in the rotary axes C and A: 9000°/min

– acceleration in the X/Y/Z axes: 2/2/3 m/s2

– acceleration in the rotary axes C and A: 500°/s2

– bidirectional accuracy in the X/Y/Z axes: 0.112/0.050/0.045 mm

– bidirectional accuracy in the rotary axes C and A: 26 arcsec

– unidirectional repeatability in the X/Y/Z axes: 0.040/0.025/0.021 mm

– unidirectional repeatability in the rotary axes C and A: 16 arcsec

– electrospindle power: 20 kW from 10600 rpm

– maximum rotational speed of the electrospindle: 24000 rpm

– number of items in the tool magazine: 16

– maximum tool diameter (position 6,7,10,11): 65 mm

– maximum tool diameter (position 1,2,3,4,5,8,9,12,13,14,15,16): 100 mm

– maximum distance between the tip of the spindle and the tip of the tool: 700 mm

– maximum tool weight: 5 kg

– maximum load of the tool magazine: 48 kg

– tank capacity of the oil mist lubrication unit: 6 l

– working pressure: 6 bar

– power supply: 400 V +10/-15%, 50/60 Hz

– electrospindle liquid cooling

– cooling of the tools with compressed air through the electrospindle

– dimensions of the Concept 40/155/25 PX5 machine without an electrical cabinet (length x width x height): 21000 x 9500 x 7500 mm

Equipment of the 5-axis machining center for aluminum and composites CMS Concept 40/155/25 PX5

– CNC control: FANUC 31i-B5

– measuring probe: RENISHAW RMP60

– control button: FANUC

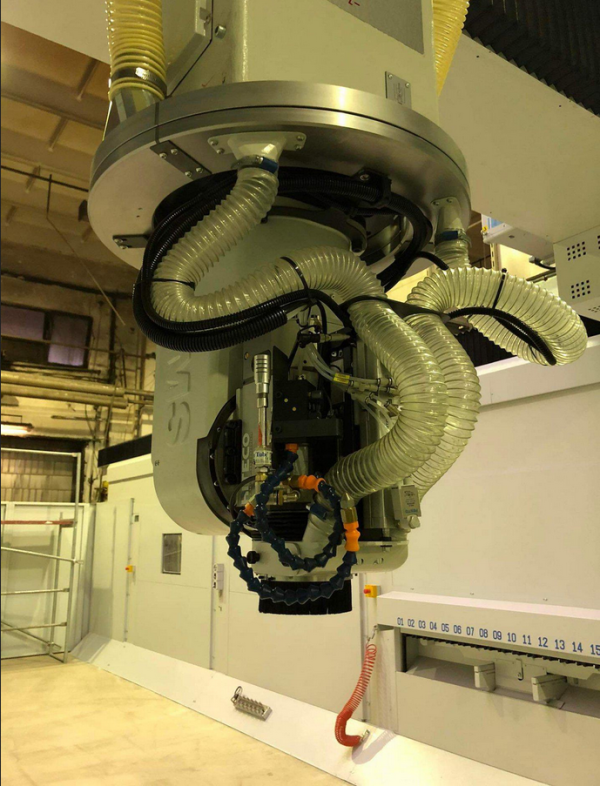

– working head: PX5

– HMI panel with a 21.5 touch screen: CMS ACTIVE

– tool holders: HSK63A

– collets: ETS 40

– axis AC servomotors

– pneumatic axle brakes

– adjustable dust extractor with rotating collector

– cold air gun

– oil mist lubrication unit

– installation of compressed air

– electrical cabinet with air conditioning

– central lubrication system

– protection against carbon fiber dust

CMS Concept 40/155/25 PX5 5-axis machining center, manufactured in 2020 in Italy, is used in various industries for milling parts made of sand, foams, epoxy and phenolic resins, carbon fiber, fiberglass, reinforcement and aluminum. The machine combines features such as durability, reliability and high precision, required when performing milling, drilling and three-dimensional machining.

The machining center for composites and aluminum is equipped with a movable bridge with a 5-axis PX5 working head, moving on two electrically welded steel guides with high rigidity. The head has a special electrospindle rotating at a speed of 24,000 rpm with an automatic tool changer. All interpolated axes (X,Y,Z,C,A) are equipped with high-class servo motors and air brakes.

The milling center for prototyping uses an advanced calculation program based on the finite element method (FEM) to dimension the structure, ensuring high geometric accuracy and reliability, even in the case of heavy workloads. The special design of the machine maintains a constant temperature of the moving parts, which allows for high thermal stability.

The easily accessible working area allows quick and easy loading of workpieces to be processed. All moving mechanisms are perfectly optimized and are driven by efficient motors, guaranteeing the highest speeds and accelerations. The machining center is offered with rich equipment, including: 21.5” HMI CMS ACTIVE touch panel with FANUC 31i-B5 CNC control and RENISHAW RMP60 measuring probe.