Description

TRUMPF TRUMATIC L 3030 – Year 2004

Power:2 kW (2000 W)

Laser type:CO2

Wavelength:10.6 μm

Working area in the x/y/z axis:3000/1500/115 mm

Feed rate in the x/y/z axis:3104/1580/122 mm

Positioning speed parallel to the axis:60 m/min

Maximum sheet thickness (mild steel):20 mm

Maximum sheet thickness (aluminium):10 mm

Average compressed air consumption:700 l/min

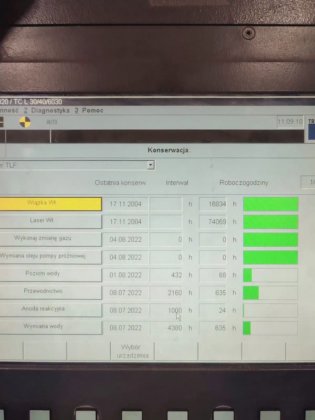

Laser beam emission time:16834 h

Connection power:73 kVA

Coupled air connection:6 bar

Nitrogen connection n2:30 bar

Oxygen connection o2:20 bar

Power supply:400 V; 50 Hz

Dimensions (l x w x h):9800 x 5300 x 2000 mm

Cnc controller:SIEMENS SINUMERIK 840

Laser source:TRUMPF TruFlow 2000

TRUMPF TRUMATIC L 3030 was manufactured in 2004. The laser cutting machine is designed for precision cutting of sheets made of mild steel, stainless steel and aluminium. High quality and precision of cutting is ensured by the reliable

laser source, which generates a laser beam with a power of 2 kW directed through a system of mirrors to the head.

Workpieces are cut on the laser cutting machine’s large working area in three axes with feed rates of 3000 mm (X axis), 1500 (Y axis) and 115 mm (Z axis). The sheets can be up to 20 mm thick (mild steel), 12 mm thick (stainless steel) or 10 mm thick (aluminium). The machine’s high-quality steel construction guarantees excellent stability during machining.

The laser cutting machine is offered with equipment consisting of, among others, a pallet changing system, servo motors for the X,Y,Z axes and a modern

CNC control for full control of the machine. The laser went through regular maintenance – the last inspection was performed in July 2022.