Description

| Metal length | 3000 mm |

| Power | 2000 W |

| Metal width | 1500 mm |

| Type | CO₂ |

| Option to cut tubes | no |

| Max thickness | 20 mm |

| CNC | yes |

| CNC type | Siemens Sinumerik 840 |

| Travel X | 3000 mm |

| Travel Y | 1500 mm |

| Travel Z | 115 mm |

| Trumpf Trumatic L3030 – Year 2004 | |

| Length x width x height | 9800.0 × 5300.0 × 2000.0 |

Technical data of the TRUMPF TRUMATIC L3030 laser cutter

– laser power: 2 kW (2000 W)

– laser type: CO2

– wavelength: 10.6 μm

– feeds in the X/Y/Z axes: 3104/1580/122 mm

– working range in the X/Y/Z axes: 3000/1500/115 mm

– positioning speed parallel to the axis: 60 m/min

– positioning speed with simultaneous operation of the X and Y axis drives: 85 m / min

– maximum detail thickness (mild steel): 20 mm

– maximum detail thickness (stainless steel): 12 mm

– maximum detail thickness (aluminum): 10 mm

– average compressed air consumption: 700 l/min

– connection power: 73 kVA

– compressed air connection: 6 bar

– nitrogen connection N2 : 30 bar

– O2 oxygen connection: 20 bar

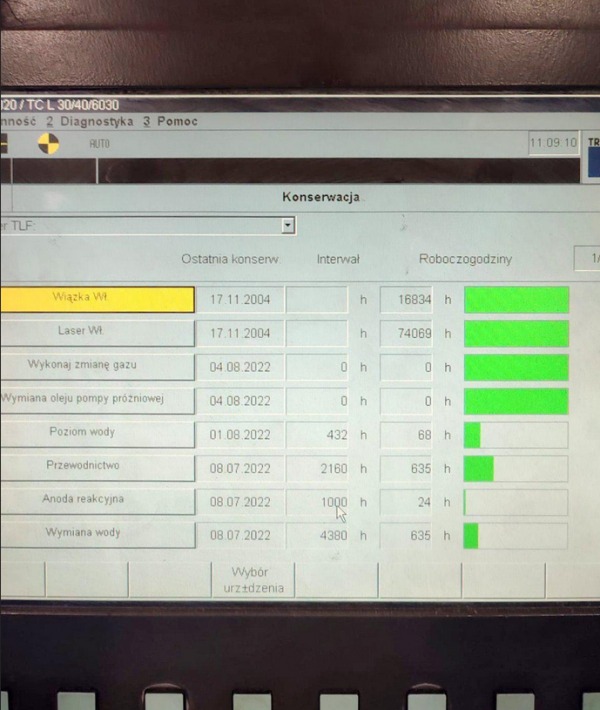

– time of switching on the TRUMATIC L 3030 machine: 74069 h

– laser beam emission time: 16834 h

– power supply: 400 V 50 Hz

– dimensions (length x width x height): 9800 x 5300 x 2000 mm

Equipment for the TRUMPF TRUMATIC L3030 laser cutter

– CNC controller: SIEMENS SINUMERIK 840

– laser source: TRUMPF TruFlow 2000

– X,Y,Z axes servo motors

– automatic pallet changer

– belt conveyor

– cutting head with lens 5

– cutting head with 7.5 lens

– APCs

TRUMPF TRUMATIC L3030 laser cutter, built in 2004, is used in the process of precise cutting in details made of mild steel, stainless steel and aluminum. For sheet metal cutting, the machine uses a reliable TRUMPF TruFlow 2000 laser source, generating a 2 kW laser beam, which is directed by a mirror system to the laser head.

The solid construction of the laser punching machine is made of high-quality steel, which ensures excellent stability and precision of processing. Sheets with a thickness of 20 mm (ordinary steel), 12 mm (stainless steel) or 10 mm (aluminum) are machined in a large working space in three axes X, Y, Z with feeds of 3000 mm (X axis), 1500 (X axis) Y) and 115 mm (Z axis).

The laser cutter is equipped with a modern CNC SIEMENS SINUMERIK 840 controller for programming the parameters of the machining process, X, Y, Z axes servo motors and an automatic pallet changer. The laser underwent regular inspections – the last inspection was made in July 2022.