Description

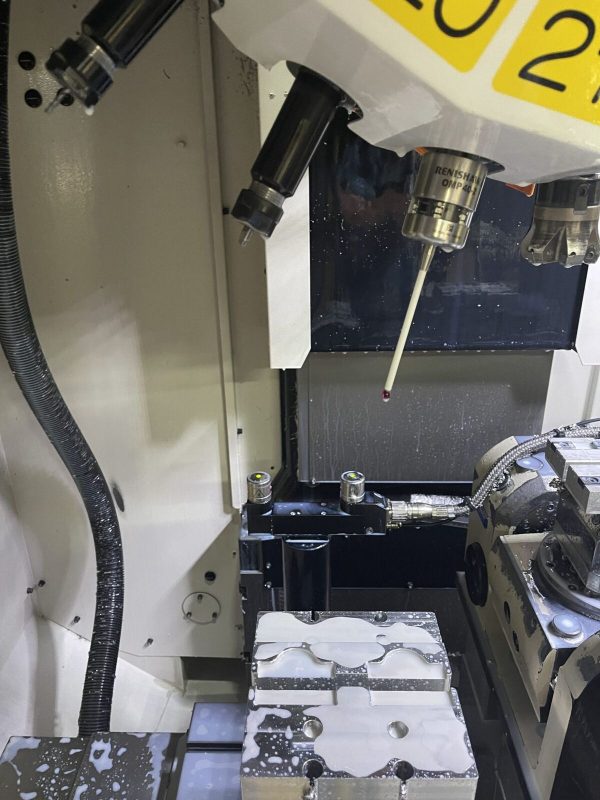

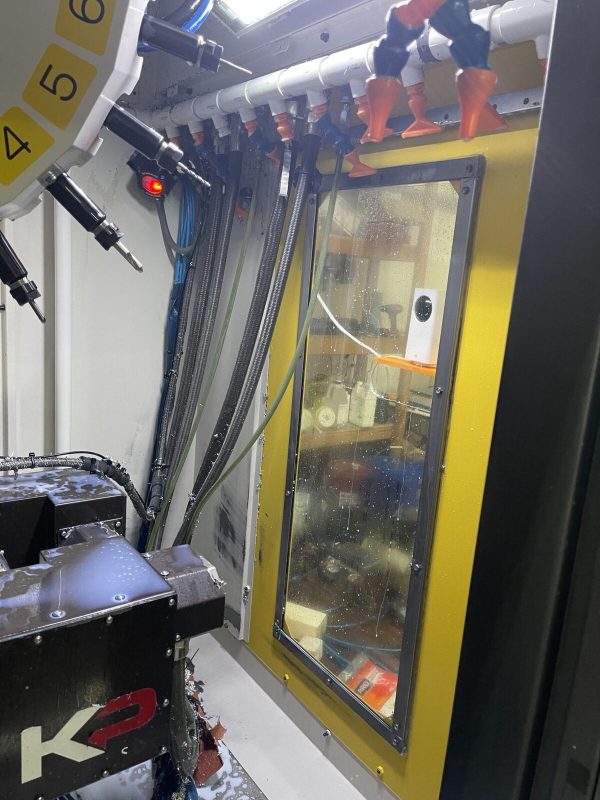

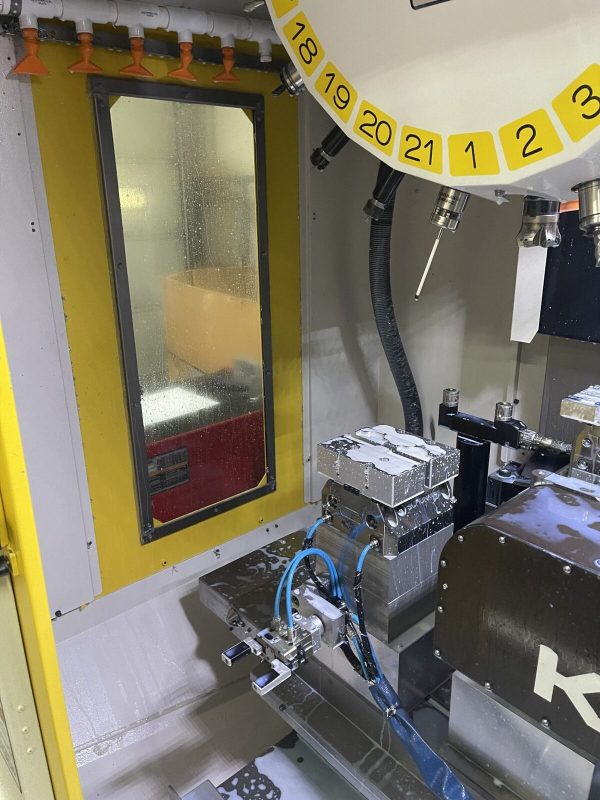

Fanuc RoboDrill 5X A-D21MiB5 Year 2018

CNC 5 Axis Tapping Center + Robot Cell

Fanuc Robot Specs (RoboDrill Specs Below These):

M-20iB/25 A-Cab R-30iB Plus Haptic – Standard Cable w/Valves

M-20iB/25 Robot with R-30iB A-Cabinet Plus NRTL Approved Controller and HandlingTool Software

M-20iB/25 Six Axis Mechanical Unit 25 kg Maximum Payload, Floor or Invert or Angle Mounted, 1853 mm Reach) with:

-ISO Wrist Flange

-Lifting Eye Bolts

-J1 axis range 360 Degrees (standard)

-Mechanical Unit Cable with:

-EE Connector at J3 with 8 inputs, 2 outputs, HBK, +24 VDC, 0VDC

-ES (Ethernet Signal) Cable with a Connector at the Base and at J3

-ASi Cable with a Connector at the Base and at J3 for User Signals, —Force Sensing, or 3DL

-COAX Camera Cable with a Connector at the Base and at J3 for 2D & 3D iRVision

-1 User air Line with Rc3/8 Inlet Port at Base and Rc3/8 Outlet Port at J3

-2 Built-in Solenoid Valves (2-position, Double acting) with Rc3/8 Air Connection Port at J1 Base and Rc1/8 at J4 Arm

-Splash-resistant Cable Cover Hood Type A on J4 Arm with Cable/hose Exit

-7 m Robot Connection Cable

-NRTL Approved FANUC SYSTEM R-30i B Plus A-Cabinet Controller with:

-Backplane 2 Slots

-Main Board A (I/O Link i slave) with:

-CPU Standard (DRAM 1GB, I/O Link I slave)

-Memory Card (FROM128MB/SRAM2MB)

-Axis Control Card 6 Axes

-2 Ethernet Ports (10BaseT/100BaseTX)

-1 iRVision GigE Camera Port

-1 iRVision COAX Camera Port

-2 Mini Slots (Supports Devicenet, PROFIBUS, EtherCat Slave, CC Link, Aux Axis, ARC Link, FL-net Plug-in Cards)

1 Wide Mini Slot (Supports PC104, Line Tracking or Profinet Plug-in Card)

-1 PCMCIA Memory Card Slot

-1 USB Port 2.0 (Accessible from the Controller Door)

-1 RS-232 Port

-Power Supply Unit (for Controller)

-6-Axis Servo Amplifier

-UL/CSA Breaker

-E-STOP unit

-2 Safety Inputs & 2 Safety Outputs

-Operator Panel (Auto-T1 Mode Switch, FAULT RESET & CYCLE START Push Buttons, E-STOP button, FAULT and POWER Indicator Lights)

-i Pendant (Hi Resolution, Haptic, Touch Panel, USB Port 3.0)

-10M Teach Pendant Cable

-1 Spare fuse kit

-Tool for Wago terminal block (for Fence / Ex. Emergency stop wiring)

-1 EE Male Connector (90-degree, 18-pin Hirose connector for user supplied EE cable)

-Product Documentation CD:

-Includes HandlingTool Software (V9.xx), M-20iB Mechanical Unit, and R-30iB Plus Controller Documentation.

-System Software Reference, KAREL Reference

-HandlingTool Software Installation, Setup and Operations

-Controller Maintenance

-Mechanical Unit Operator Manual Error Codes

Options documentation (software/hardware)

Fanuc RoboDrill Specs:

X-Axis Travel: 19.68″

Y-Axis Travel: 15.74″

Z-Axis Travel: 12.9″

∙ 25.6” X 15.74” Table Area With A 660 Lbs Load Capacity

∙ 200-24,000 RPM Direct Drive High Torque Spindle

∙ 200L Coolant Tank

∙ Optional Fully Integrated 4th Axis and 5th Axis

∙ BT-30 Spindle Taper with “Big Plus” Dual Contact Spindle (four bearing design)

∙ 21 Position, Bi-Directional Tool Changer (New Design)

∙ “Quick” ATC Recovery System

∙ 1.6 Second Tool Change Time (Chip to Chip)

∙ 0.9 Second Tool Change Time (Tool to Tool)

∙ 5,000,000 Duty Cycle Time

∙ Rigid Tapping up to 8,000 RPM

∙ “Quick” Tap Recovery System

∙ High Speed Reverse Tapping

∙ Thread Milling

∙ Helical and Linear Interpolation

∙ 1 Millisecond Servo Response Time

∙ Three Axis Simultaneous expandable to Five Axis Simultaneous

∙ Custom PMC

∙ Simultaneous ATC / Table Positioning

∙ 2125 IPM Rapid Rate – X, Y, Z Axis

∙ Feed Rates to 1181 IPM X, Y, Z

∙ Multi Step Skip

∙ AI Contour Control I

∙ Nano CNC System

∙ Ultra Precise 32,000,000 Pulses/Rev encoders

∙ 1.5 G Acceleration

∙ Thermal Growth Compensation

∙ 2 MB Memory

∙ 1,000 Registerable Programs

Fanuc Robodrill αD21MiB5 24,000 RPM

CNC Vertical Machining Center

Standard Features (continued)

∙ Smart Backlash Compensation

∙ HRV3 Plus

∙ Tool Compensation Memory C

∙ Tool Offset Pairs 200 Pairs

∙ Part Program Storage 2 MB

∙ 6 + 48 Work Offsets

∙ Coordinate System Rotation (G68.G69)

∙ Coordinate System Setting (G92)

∙ Custom Macro B

∙ Canned Cycles for Drilling (G73, G74, G81~G89/G80)

∙ Manual Handle Feed

∙ Coolant System- 200 Liter Coolant Tank and Spindle Coolant Nozzle

∙ Coolant & Chip Splash Guard

∙ Skip Function (G31)

∙ Background Editing

∙ Dynamic Graphic Display

∙ On Screen Display of Spindle ‘ RPM’ and ‘Load’ Meters including cutting time count down

∙ Basic Metal Top Cover

∙ Leveling Bolts and Pads

∙ Alpha Numeric Keyboard

∙ Automatic Lubrication System

∙ NEW! Perodic Maintenance Management

∙ Quick Side (Operator Interface)

∙ Manual Guide for Milling (Shop Floor Programming System)

∙ Manuals (1) Each: Operators, Maintenance, Parts, Operators CNC, & Maintenance CNC

∙ MistBuster Mist Collector

∙ Interior Work Light – LED STYLE

Fanuc Robodrill αD21MiB5 24,000 RPM