Description

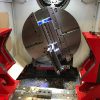

Master RMT TGB 32 Inch Pipe Threading Machine

Condition: New

RMT PIPE SPOOL MASTER Series of pipe facing lathes.

Many shops, depending on equipment, will put out 1-4 larger diameter pipes a day with

the machined bevel quality required; taking anywhere from 1-4 hours per pipe to

set up and “machine” the end of the pipe.

The new RMT PIPE SPOOL MASTER Series machines can reduce that time down to 15-30 minutes including setup. The machine does not spin the pipe, but rather clamps and centers the material, while a

facing head spins and approaches the material while inside the machine. 12” XH

wall (1-1/2”) P91 pipe processed with a complex bevel including C-dimension was

processed in 20 minutes.