Pimpel GmbH

The enterprise was founded in 1996 by Ing. Friedrich Pimpel. 2013 more than 500 success full customers profit from the persistent focus on IT and Manufacturing Technology. We would be pleased to send you our list of references.

Our employees carry the slogan “get the work flow” daily to manufacturing enterprises and develop together with customers and partners efficient and modern solutions.

Due to many years of experience – not only in the software sector but also in the production – it is possible for us to offer customized, practically oriented overall solutions. Moreover we are able to develop complicated post processors for all CNC-controls.

Enterprise history

1996 SmartCam/Camand

1999 Esprit

2007 CHECKitB4 and ToolShapes

2007 founding of the Pimpel s.r.o in Czeck Republic

2009 founding of the Pimpel GmbH in Germany

2009 Award Best Sales Partner ESPRIT

2010 Award Best Sales Partner ESPRIT

2011 cooperation with Greenock Benelux

2011 Award Best Sales Partner ESPRIT

2012 Award Best Sales Partner ESPRIT

2012 founding of the Pimpel CAD/CAM GmbH & Co. KG in Germany

2013 Expansion of the company location Germany

2014 Award Best Sales Partner ESPRIT

2015 Award Best Sales Partner ESPRIT

2017 Award Best Sales Partner ESPRIT

CHECKitB4

Software for NC simulations

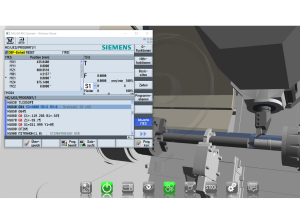

Finally, an amazingly realistic, highly intuitive representation of automation and control technology: This high-end product guarantees you optimum productivity and quality in manufacturing on the virtual machine model.

With CHECKitB4, control sequences can be simulated in their full functionality. NC programs, including all high-level language elements, can be checked for syntactic correctness and sequence capability, the absence of collisions in the workspace, the workpiece geometry and the motion behavior can be reliably evaluated, and program runtimes can be determined. Here, too, CHECKitB4 clearly differs from conventional CAM simulation.

Based on a virtual NC control(vNCK)!

Immediately after creating the NC program, the NC code is simulated on the basis of the NC kernel from Siemens or Heidenhain. There is no interpreter running in the background! The control is booted at the PC with all the machine specific parameters (machine DNA like axis parameters, traverse limitations, special cycles, subroutines ) and the NC program is processed like at the machine. Thus, immediately after completion of the CAM process, the NC program including all high-level language elements is checked for syntactic correctness and runability, the absence of collisions in the working area, the workpiece geometry and the movement behavior are reliably evaluated, and program run times are determined. Long before the machine is set up, any errors can be detected and corrected without disrupting the production flow. In short: exactly what you are looking for!