Description

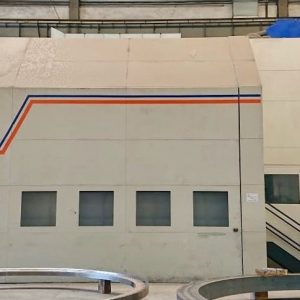

Gleason PFAUTER PE-1000 – Year 1998

CNC FULL UNIVERSAL GEAR HOBBING MACHINE 6 Axis

PFAUTER #PE-1000 6-AXIS “CNC” FULL UNIVERSAL GEAR HOBBING MACHINE

NEW 1998,

MODEL PE-1000

SUITABLE FOR THE HOBBING OF SPUR AND HELICAL GEARS,

PINIONS SPLINES, WORM-GEARS, SPROCKETS, AND OTHER

WORK-PIECES OF SIMILAR PROFILE UP TO 40″ (1000MM)

PITCH DIAMETER

EQUIPMENT / FEATURES:

UNIVERSAL HOB HEAD WITH TANGENTIAL HOB SLIDE FOR

shifting

DOUBLE WORM DRIVE FOR COMPLETE BACKLASH ELIMINATION

AXIAL AND RADIAL FEED VIA DC DRIVE AND BALL-SCREW,

HARDENED AND GROUND, WITH PRE-LOADED NUT

RAPID TRAVERSE FOR HOB SLIDE AND WORK SLIDE:

AXIAL 750 MM/MIN (29″/MIN)

RADIAL 500 MM/MIN (20″/MIN)

SINGLE START DUAL INDEX WORM(S), WORM GEAR OF BRONZE

OPTIONAL EXTENDED HEIGHT – TAILSTOCK COLUMN W/HYDRAULICALLY RAISED/LOWERED “SWING-AWAY-TYPE” TAILSTOCK W/SWING-AWAY TAILSTOCK

COMPLETE ENCLOSURE WITH SPLASH GUARD DOOR

COMPLETE COOLANT SYSTEM PUMP, PIPING, W/POWER

MAGNETIC CHIP CONVEYOR

AUTOMATIC RECIRCULATING LUBE SYSTEM W/FILTER

ONE (1) HOB ARBOR W/NUTS & SPACER-BUSHINGS

(DIAMETER )

FULL COMPLEMENT OF ELECTRICS (MOTORS/CONTROLS)

* PRESENTLY ARRANGED FOR 480 VOLT, 60HZ OPERATION

SIEMENS SINUMERIK “SYSTEM-3” CONTINUOUS PATH “CNC”

CONTROL FOR LINEAR MOTIONS W/INCREMENTAL MEASURING

SYSTEMS,DIGITAL POSITION READ-OUTS AND INTEGRATED

PROGRAMMABLE CONTROL FOR AXIAL, RADIAL, AND

TANGENTIAL MOTIONS, HOB-HEAD SWIVEL WITHIN WORK

CYCLES, HELIX ANGLE, HOB AND TABLE REVOLUTIONS.

SIEMENS AXIS DRIVE AND SPINDLE DRIVE WITH SIEMENS AND

HELDT & ROSSI TABLE INDEX, WITH SYCHRONIZATION OF

HOB AND TABLE ROTATION VIA PFAUTER “GEARTRONICS”

ELECTRONIC-GEAR-BOX.

( CNC-CONTROLLED CYCLES / FUNCTIONS / FEATURES )

– FEEDS PER WORKPIECE REVOLUTION

– AXIAL HOBBING, RADIAL & AXIAL HOBBING

– HOB SHIFTING AND PRECISION HOB SHIFTING

– MULTI-CUT CYCLE W/FEED & SPEED CHANGE

– CROWN HOBBING WITH MAXIMUM CONTOUR RADIUS OF

99.99MM (VIA CIRCULAR INTERPOLATION)

– TAPER HOBBING WITH DESIRED ANGLE (VIA LINEAR

INTERPOLATION)

CNC CONTROLLED CYCLES PROVIDE VARIOUS COMBINATIONS

OF THE ABOVE, INCLUDING TWO-CUT-WORK CYCLES WITH

SPEED AND FEED CHANGE BETWEEN CUTS,

DWELL-AT-CYCLE-END,AS WELL AS OTHER AXILIARY

functions

OPERATOR’S DIALOGUE PROGRAM IN EITHER MM OR INCH,

WITH DATA ENTRY PROMPTS VIA THE CNC FOR NUMBER

OF TEETH IN WORK-PIECE, HELIX ANGLE, NUMBER OF

HOB-STARTS, ETC.

DIRECT PROGRAMMING OF HOB SPEEDS VIA THE CNC

SMALLEST PROGRAMMABLE INCREMENT (0.001MM)

NOTE – THIS IS A RETROFIT CANDIDTE ONLY. SELLING AS IS.

F.O.B. OUR WAREHOUSE