Description

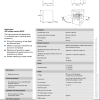

Datron M7HP – Year 2012

CNC Machining Center

48,000 RPM HSK-E 25 Spindle!

Spindle run time: 1125 hours

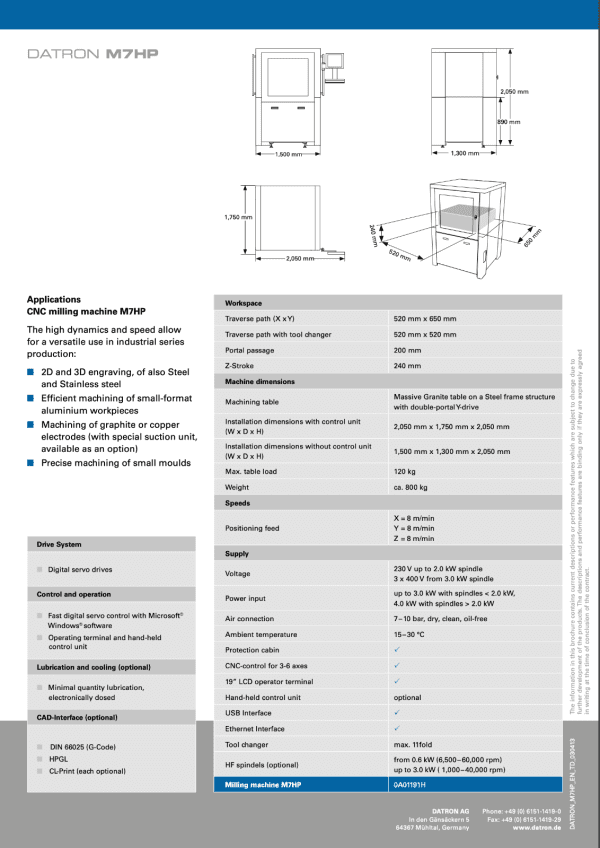

Datron M7HP Machining System

– Gantry-style machining system with fabricated steel bridge filled with polymer-concrete for vibration dampening and stability (8” gantry clearance)

– Solid granite table with 20″ by 20″ work envelope

– Precision fine pitch ballscrews

– Digital servo drive system complete with ground ballscrews on each axis, two linear guide ways per axis, precision encoders on each drive motor with index pulse disc on each ballscrew and over-travel limit switches.

3D-CNC control software for DATRON CNC machine: Windows based control software allows user to operate the machine. Comes complete with conversational control.

High frequency 1.8 kW spindle with HSK-E 25 collet system: – 5,000 to 48,000 RPM range

– Comes complete with high frequency converter.

– Ideal spindle in applications when surface finishes are critical. This spindle is intended for industrial engraving and mold making applications.

HIB Spindle cooling unit

High Frequency Speed Control for Spindle: Software and hardware option allows variable speeds through control software.

Tool change unit with 11 tool capacity for HSK-E 25 collets: Pneumatic (drawer style) tool change magazine comes complete with tool length sensor. Positions 1-11.

CNC Hand Held Control Unit

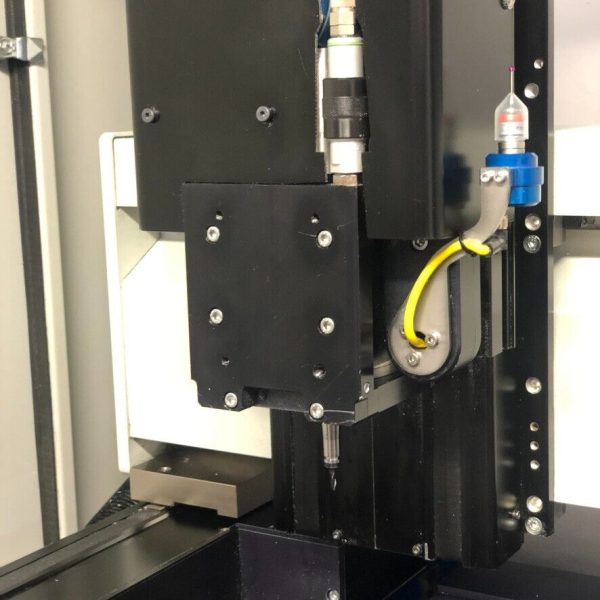

Z-height surface sensing precision probe TP-R: The high precision probe uses Renishaw TP20 magnetic break-away head with replaceable ruby tips.

3D Software Extension for Z probe: Software option allows user to edge find for quick set-up and exporting of x,y data points.

I/O control board and software for external automation interfacing: Digital I/O module offer 8 inputs and 8 outputs rated for 24 volts at 200 mA.

Compact 4th and 5th rotary axis: Full rotation on 4th axis and 300 degree positional on 5th axis.

Additional Compact Rotary 4th/5th included for parts.

Minimum Quantity Lubrication System with nozzles from Datron M8 retrofit onto this machine. Allows for better chip clearance.

We ran oil mist in the MQL system. The attached mist extraction system will be delivered without a HEPA filter. This machine was only used to cut aluminum and polycarbonate.

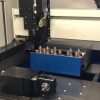

Tooling plate, with eight manual operation 3″ ID holding chucks.

Tooling plate, with eight manual operation 4″ OD holding chucks.

Enough HSK-E25 tool holders, collets and other accessories to make parts on delivery.

Manuals, service tools/supplies, and anything else we forgot to list, but have lying around for this machine will be included.