Description

OKUMA MB-5000H – Year 2014

CNC 4-AXIS HORIZONTAL MACHINING CENTER with 2 Pallets

Okuma MB-5000H

Y.O.M.:2014

Built in 2016

Okuma Space Center MB-5000H SPECIFICATIONS:

X-Axis (Column Right/Left)…………29.92″

Y-Axis (Spindel Up/Down)…………29.92″

Z-Axis (Table Front/Back)…………29.92″

Spindle Center to Table Surface…………1.97″ to 31.89″

Spindle End to Table Center…………5.31″ to 35.24″

Table (Pallet) Size…………19.69″ x 19.69

Load Capacity – Maximum…………1,000 Lbs.

Optional Index Positions…………360,000

Spindle Speed – Maximum…………15,000 RPM

Rapid Feedrate(X-/Y-/Z-xis)…………2,362.20 ipm

Jog Feedrates (X-/Y-/Z-Axis)…………0.04 to 2,362.20 ipm

Tool Magazine Capacity…………64

Taper…………Cat 40

Tool Diameter – Maximum…………2.76″

Without Adjacent Tools…………5.91″

Tool Length – Maximum…………11.81″

Tool Weight – Maximum…………22 Lbs.

No. of Pallets…………2

Spindle Drive [Standard (Wide Range)]…………40 HP

X-Axis Feed…………6.13 HP

Y-Axis Feed…………6.13 HP

Z-Axis Feed…………6.13 HP

Hydraulic Power Unit…………3 HP

Table Indexing…………4.00 HP

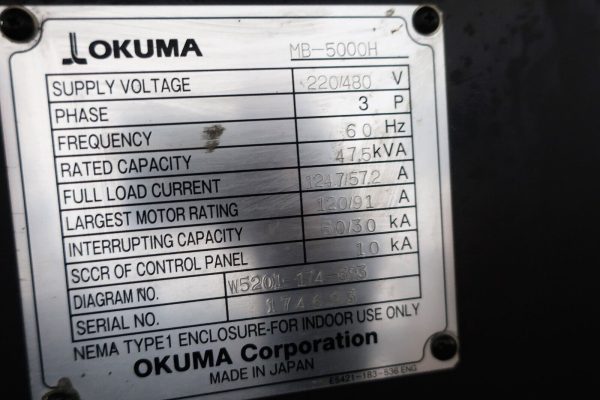

Power Requirements…………kVA 45 (15,000)

Voltage…………200V VAC +/- 10%

Frequency…………50/60 Hz

Machine Height…………113.35″

Floor Space…………102.56″ x 181.50″

Machine Weight…………27,500 Lbs.

Equipped With

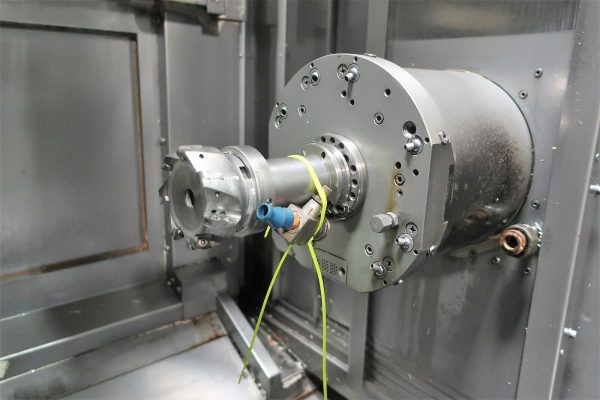

OKUMA OSP P300M CNC CONTROL

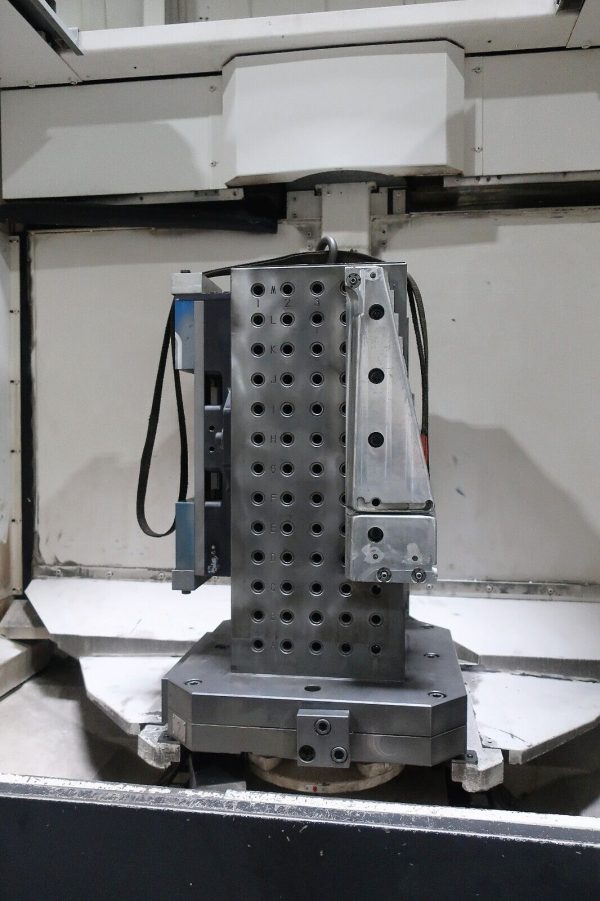

20″ X 20″ PALLETS

FULL 4TH AXIS TABLE

15,000 RPM SPINDLE

40 TAPER

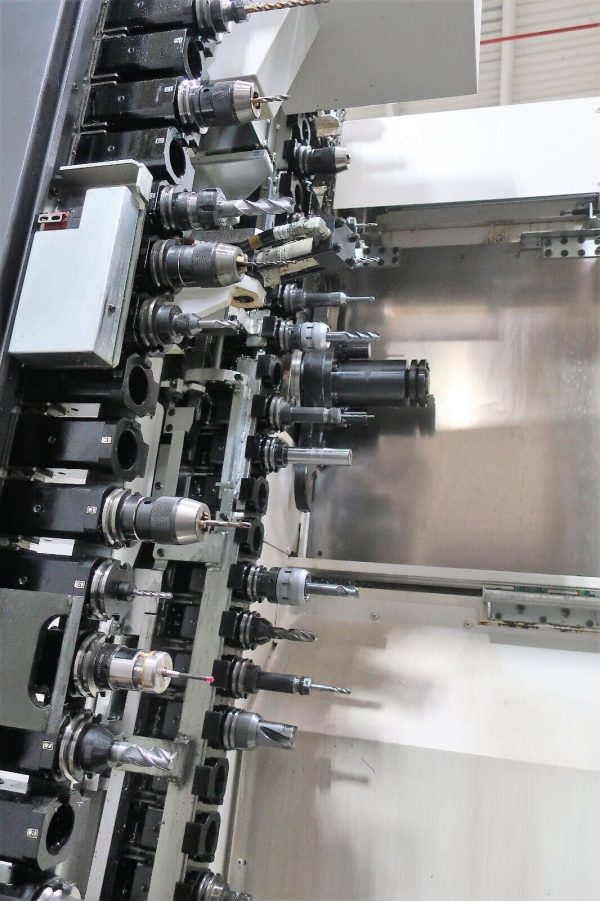

64 POSITION TOOL CHANGER

MP HIGH PRESSURE COOLANT PUMP

THRU SPINDLE COOLANT

TURBO CHIP CONVERYOR

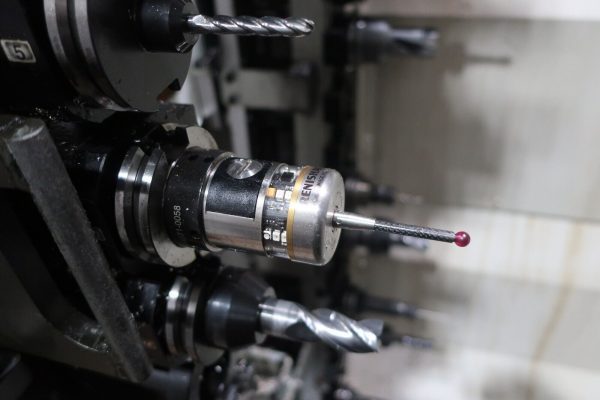

RENISHAW PROBING

TOMBSTONES INCLUDED

APPROX. 20 TOOL HOLDERS INCLUDED

***WAS CUTTING ALUMINUM***

Data Card options:

OSP Suite

tool breakage

machine management

optical probe (Not sure probe is with the machine)

macro 100/20

feed backlash function

gauging/zero

graphic

inductosyn B

Animation

tool life management

spare T1.change

helical cutting

One-direct position

skip function

change work coordinates

angle chamfer

exact stop

mirror image

work coordinates

simple load monitor

3D simulation

synchronized taping

cancel axis

sequence stop

multi volume machining

manual gauging

IMAP playback

system variables

add math function

sub programs

xyz self tun

PL speed clamp

remote api suite

axis active stop, eco suite

com.var. 2000 set

tool data 999

touch sens move

cycle time reduction

coolant high pressure

oil hole

thru spindle tool

air blast

flood and shower wash