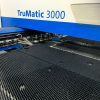

Description

TRUMPF TruMatic 3000 – Year 2007

CNC Punch Machine

Brand :TRUMPF

Mode : TruMatic 3000

Year of construction: 2007

punch

x-axis 2500 mm

y-axis 1250 mm

Sheet thickness – max. 6.4 mm

Workpiece weight max. 150 kg

Punching force max. 180 kN

Operating hours approx. 46000 h

Dimensions 6282x6548x2200mm

Equipment/accessories:

– Control BOSCH PNC-P

– TRUMPF TruCoax 2000 CO2 laser

– Working area 2175 x 1250 mm (2500 x 1250 with repositioning)

– Paintwork white RAL 9002, gentian blue RAL 5010

Standard equipment machine:

– Stable, easily accessible C-frame

– Coordinate guide for high-precision processing – Linear magazine including 2 clamping claws

– Maintenance-free drives

– Repositioning device with programmable hold-down device

– Brush tables

– Parts chute 300 x 500 mm

– 1 good parts box

– Chip container

TRUMPF lasers:

– TruCoax 2000 CO2 laser

– High frequency excitation

– Cooling unit

– Laser control TASC 3

– Closed beam guidance

– Programmable cutting gas pressure

– Laser cutting head with 7.5″ lens

– Cutting head quick-change device

– ControlLine

– FocusLine

– NitroLine

– SprintLine

– ContourLine

punching head:

– Hydraulic punching head

– Mono tool holder

– 360° rotation of all tools

– Programmable hold down

– Tool length compensation

– Tool spray lubrication

– Slug extraction

– Reshape

Steering:

– Open control based on Bosch PNC-P

– Control panel with TFT color screen 15″

– Programming management

– Online help

– Integrated e-shop

– Diagnostic function including logbook laser

– Integrated technology data

– Teleservice

Data transfer:

– USB interface and network connection

Security:

– CE marking

– Photocells

– Monitoring system for gas, temperature, cooling water, etc

– Fast shutdown

– Protection against scattered radiation

– Compact dedusting system

Extended laser equipment:

– Air cutting Advanced punching equipment:

– Function MultiTool

– Function MultiBend

– Thread forming function

– Rolling technology function

– Spray lubrication die

Extended machine equipment:

– 1 additional clamp

– Repositioning cylinder with height-adjustable thrust pads

– Parts chute sensor

– Anti-vibration installation

– Automatic switch-off

Special sheet metal processing:

– Sheet metal gentle die ball