Description

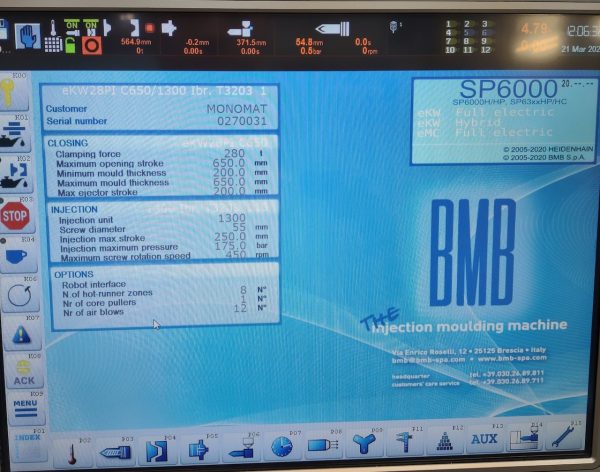

BMB SPA eKW28PI C650/1300 Hybrid – Year 2020

Injection moulding machine 1300 Ton

13000 RUNNING HOURS

PERFECT CONDITION

READY FOR PRODUCTION

OPTIONAL EQUIPMENT : SIDE ENTRY AUTOMATION SUITABLE FOR IML – UPPON REQUEST

Catalogue Info :

eKW Hybrid

BMB capitalized on all the experience gained in two specific areas, the one dedicated to fast cycling machines and the other dedicated to full electric technology, and created this innovative series that combines their advantages i.e. large capacity injection unit, precision, speed, robustness and low power consumption. Furthermore, the performance of the control unit, easily programmable and able to ensure extreme flexibility, makes the series user friendly. All the foregoing encapsulated within a range of models able to meet any requirement, with machines from 160tonnes up to 2200tonnes clamp force.

CLAMPING UNIT

By using the special KW clamping system, platen deflection is eliminated, perfect parallelism is ensured and longer opening strokes are an additional bonus.

Platen movement is by special satellite roller recirculation screws, with direct in line drives that ensure high load capacity and better performance.

The machine reliability and rationality is enhanced by reduced footprint, brushless motors, liquid cooled and optimum cleanliness of the mould area.

INJECTION UNIT

The injection piston, perfectly balanced hydraulically, is connected directly to the plasticizing screw and rotates during the dosing phase.

This technical solution avoids the use of wear items such as thrust bearings, usually fitted inside the piston and further, the application of the Torque motor for the screw rotation on the same axis of the piston itself excludes any additional mechanical parts, such as gears and belts.

The injection phase is controlled via a Moog servo valve and a hydraulic accumulator system.

NUMERIC CONTROL SYSTEM

All the BMB machines motors and hydraulic-mechanical functions are controlled by a special CNC machine tool numeric system perfected in the company to ensure the best performance in total safety. The drivers, which are interconnected and interact in real time and recover the braking energy, increase the energy efficiency of the system.

The system is completely integrated for the setting and control functions, making it easy to reach the parameters set for all the cycle values. The setting procedure is considerably simplified requiring only three values of position, speed and force to be set.

The IT intelligence manages perfectly all operational requirements, reaching quotas set accurately and automatically adjusts acceleration and deceleration.

CONTROL SYSTEM REMOTE ASSISTANCE

Remote assistance allows diagnosis and interventions on the injection molding machines control system. Communication with eKW Series machines uses a network connection via TCP / IP software installed on the PC that will communicate with the machine.

In moulding departments this means information accessibility in “real time” on the machine movements and performance with the possibility of intervening, if necessary, on the working parameters and modify them instantly.

Monitoring the moulding parameters centrally, you can get details on the machines operation, control its performance, receive sms or e-mail on your smartphone in case of alarm, with detailed description of these anomalies.

Acquiring the production data for each shot, at a central level, it is possible to meet the ISO standards, related to the quality and traceability of each piece control, produced by the machine, which is critical not only for the pharmaceutical and food sectors, but currently for each application area.