Description

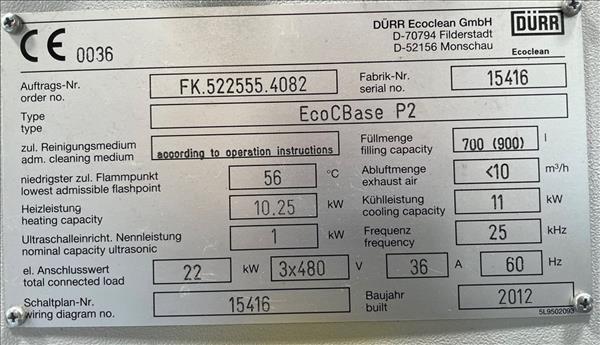

DURR EcoCBase P2 Hydrocarbon Parts Washer – Year 2012

Basket Dimensions: 21″ L x 12″ W x 8″ D

Max. Batch Weight: 110 lbs

Feed Height: 31.5″

Throughput: Approx. 7 Charges / Hour

Flood Tank Capacity: 60 Gal.

Distillation Unit: 35 Gal.

Electrical: 3 / 60 / 480V

Usable Solvents

Aliphatic & Napthenised Hydrocarbons

Polar & Partially Polar Solvents

Other Non-Flammable Solvens Possible

Equipped With:

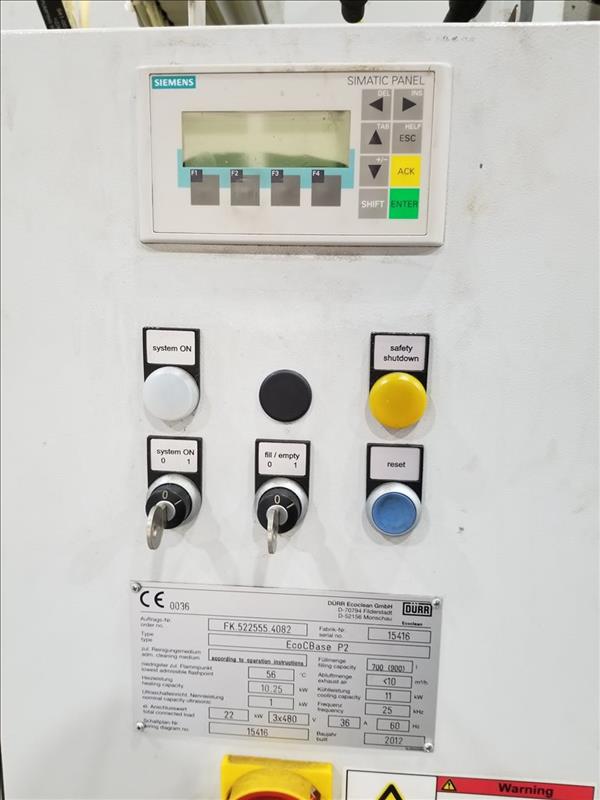

Siemens S7 Programmable Controller

Vacuum Distillation

Cleaning & Pre-Cleaning Tanks Ultrasonic Device

Circulation Filtration

Bypass Filtration

Spray Cleaning

Emulsion Separation

Manual or Automatic Feed of Working Chamber Front Side

Enclosed Cleaning & Drying Chambers

Rotational & Swivel Cleaning & Drying Assist

Continuous Separation of Low Boiling Substances & Water

What is Hydrocarbon Parts Washer Machine?

A hydrocarbon parts washer machine is an industrial cleaning equipment used for cleaning and degreasing parts or components in manufacturing processes, maintenance operations, or other industrial applications. It uses a hydrocarbon-based solvent as the cleaning medium to remove contaminants such as oil, grease, dirt, and other residues from parts or components.

Hydrocarbon parts washer machines typically consist of a tank or chamber for holding the cleaning solvent, a pump or agitator for circulating the solvent, and various features such as heating elements, filters, and drying systems to enhance the cleaning process. The parts to be cleaned are usually loaded into a basket or fixture and immersed in the hydrocarbon solvent, where they are cleaned through immersion, agitation, or a combination of both.

Hydrocarbon solvents used in parts washer machines are typically formulated from petroleum-based hydrocarbons, such as mineral spirits, naphtha, or other similar solvents. These solvents are effective at dissolving and removing various types of contaminants from parts, including oils, greases, waxes, and other organic residues. Hydrocarbon solvents are also known for their good material compatibility, as they are less aggressive compared to some other types of solvents, making them suitable for cleaning a wide range of materials, including metals, plastics, and elastomers.

Hydrocarbon parts washer machines are commonly used in industries such as automotive, aerospace, electronics, machinery manufacturing, and general manufacturing, where parts or components need to be cleaned and degreased as part of the manufacturing, maintenance, or repair processes. They are often chosen for their effectiveness, versatility, and environmental friendliness, as hydrocarbon solvents are typically less hazardous and less environmentally harmful compared to some other types of solvents commonly used in industrial cleaning processes.