Description

SMT SX 4000 – Year 2017

CNC Horizontal Machining Center with 2 Pallets

Make SMT

Model SX-4000

Year 2017

SPINDLE

TOOL CHANGER

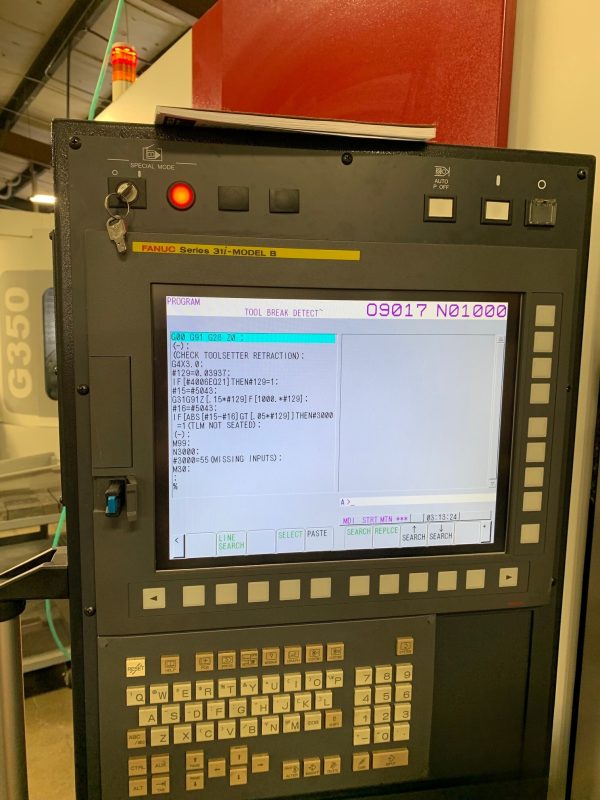

CONTROL

OPTIONS

Spindle Center to Pallet Surface: 3.15″ – 25.2″

Spindle Gage Line to Pallet Center: 1.97″- 29.13″

Pallet Change Time, Two Station APC: 9.0 sec (JIS)

Spindle Ranges, Automatic Selection Electrical 2 Steps

Spindle Bearings Bore Diameter: 2.76″

Spindle Bearings Lubrication Oil & Air

Spindle Torque Maximum: 184 ft-lbs. (10%ED)

Axis Motor, Digital Servo X/Y/ Z Axes: 7.5 HP

Axis Thrust Maximum X Axes: 4108 lbs.

Axis Thrust Maximum Y/Z Axes: 3081 lbs.

Magazine, Cassette Tool Pot Type (Includes Spindle): 60

Tool Shank Cat ” V ”

Tool Change System: Double Swing Arm

Tool Selection Address Fixed Random Method

Coolant Pressure: 64 PSI

Coolant Spindle Nozzles: 6

Ceiling Shower Nozzles: 14

Positioning, Digital Encoder: +/- 0.000098″

Repeatability, Digital Encoder: +/- 0.000059″

Indexing Accuracy/Positioning: +/-. + / – 2.50 sec

Pallet Positioning Repeatability: + / – 0.00039″

Coil Chip Conveyors (2), Left and Right Side of Pallet

Coolant Shower Flush

Four Tapered Cone Pallet Positioning

Fully Enclosed Automatic Splash Guards

Heavily Ribbed One Piece T-Shaped Bed Construction

Large Linear Cross-Roller Guides – Auto Grease Lubrication

Magazine Interrupt Function

Metal Shutters on X, Y, and Z Axes

Operator’s Splash Guard Door with Safety Interlock

Spindle Oil Cooler

Lift Up Conveyor Hinge Belt

116 Tool Magazine (60×2)

Additional Pallet Tapped Type

MH250 Turbo Mixed Materials Lift Up Aluminum Fine

Chips and Coarse, and Stringy

Air Blow Nozzle

Additional M Code, (8) Sets

Coolant Spray Gun 0.25 kw Pump

BT Tooling Retrofit Cost (Return of CAT40 Arm Required)

Constant Hydraulic Fixture Coupling

NC-4 Split Beam Automatic Tool Length/and Diameter

Measure System

Tool Monitoring Systems Soft AC – Adaptive Control Function

Tool Breakage Detection in the Magazine