Description

CMZ TA25YS CNC Turning Center

For sale here is a CMZ TA25YS. The machine was built in 2021 and has just 3644 operating hours. Production ran in one shift.

The machine can be viewed with pleasure.

The invoice is issued with VAT.

Information about the machine:

Standard equipment for TA series:

Interpolating and bidirectional compensation of mechanical errors through laser measurement

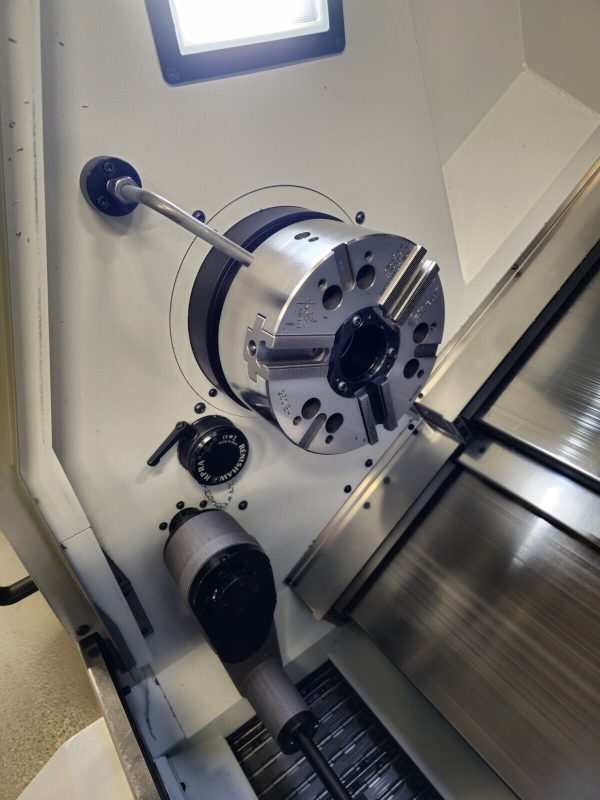

main spindle:

Oil-cooled main spindle unit

Foot pedal for opening and closing the chuck

Load indicator for main spindle motor

Safety device against opening of the chuck in the event of a drop in hydraulic pressure

C axis on main spindle (TA-15/20/25/30-M,Y,TM,TY,MS and YS):

Full C axis with positioning and clamping every 0.001 degrees

Direct encoder system for maximum precision

Hydraulic disc brake for C-axis

Switching from spindle to C-axis mode without approaching the zero point

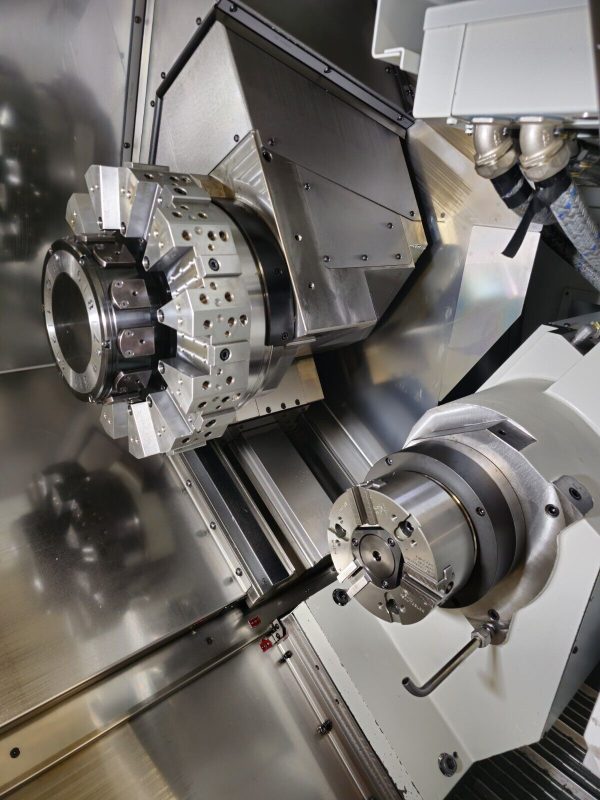

Counter spindle (TA-15/20/25/35 -S,MS and YS)

Oil spindle cooling

full clamping cylinder

Foot pedal for opening and closing the chuck

Load indicator for spindle motor

LPS in counter spindle

Safety device against opening of the chuck in the event of a drop in hydraulic pressure

C axis on counter spindle (TA-15/20/25/35-MS and YS):

Full C axis with positioning and clamping every 0.001 degrees

Direct encoder system for maximum precision

Hydraulic disc brake for C-axis

Switching from spindle to C-axis mode without approaching the zero point

Spindle synchronization (TA-15/20/25/35 -S,MS and YS)

High-speed spindle synchronization via fiber optic cable (including angle synchronization in TA-15/20/25/35-S,MS and YS)

Part transfer to counter spindle with programmable transfer pressure via B-axis

tool turret:

12 position servo turret with hydraulic clutch

Locking of the turret disc via triple sprocket, 230 diameter

Changeover time 0.15 seconds (station to station) by switching without lifting the turret disc

Powered tool (TA-15/20/25/35-M,TM,Y,TY,MS and YS)

Drive via Gleason gearing (curved gearing), hardened and ground

Direct tapping / rigid tapping

All stations powered

Helical interpolation (circular interpolation in 2 axes and simultaneous linear interpolation with a third axis) GOM704A2600

Various:

Electronic hand wheel

parts counter

Complete hydraulic equipment and installation

Automatic lubrication system

Safety monitoring against malfunctions in the lubrication system

Extra pipe for draining used lubricating oil. As a result, no contamination of the coolant

Complete installation of coolant circuit with electrics, pump and tank

Easy access for cleaning the coolant reservoir

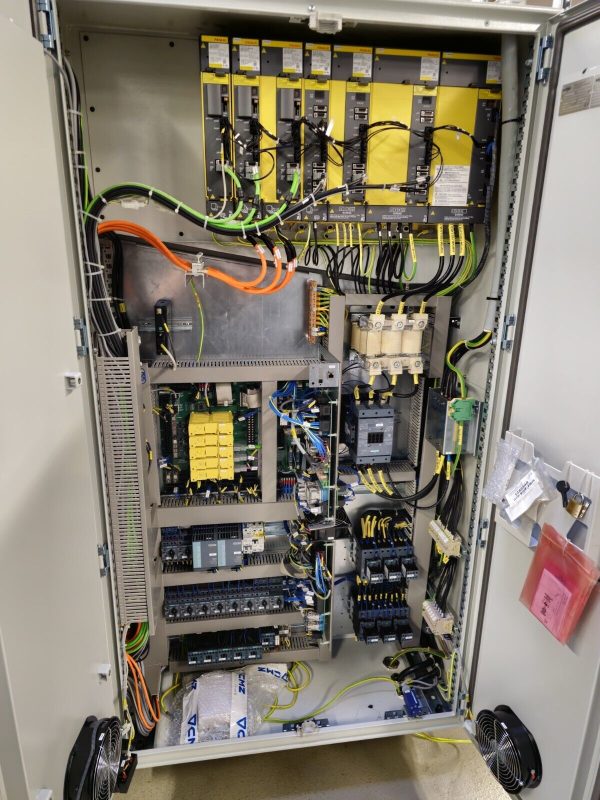

Complete electrical installation at 400 volts 50 Hz

Heat exchanger on the switch cabinet – therefore no direct connection of the switch cabinet to the outside air

workroom light

Unimag bar feeder software interface

Transport and lift kit incl. 3 Kevlar ropes

Closed splash guard

1 set of service tools

Operation and programming manuals

Wiring diagrams and maintenance manual

Accessories for TA Series:

Machine language German

G codes type A in Fanuc control

Machine manuals in pdf format available for download at cloud.cmz.com

Tool turret standard with 12 positions

Hydraulic hollow clamping cylinder (standard) in main spindle (TA25 Autoblok VNK 150-67)

LPS in main spindle hydraulic cylinder

Adjustable blow-off device for main spindle

BHD 250 3-jaw power chuck in the main spindle with a set of soft top jaws

Hainbuch Nova combi pull-back 65 (standard) collet chuck for main spindle

BBD 175 3-jaw power chuck for sub-spindle with a set of soft top jaws

Hainbuch Nova Kombi Axfix 65 (standard) collet chuck for counter spindle

tool presetter

Lateral chip conveyor for Z=640 bed (standard version)

machine status light

Tool life monitoring (tool life management)

Tool load monitor

High-pressure coolant pump with three programmable pressure levels (35, 15 and 6 bar), incl. replaceable 75 mm filter

coolant washer nozzle

Programmable, automatic parts catcher (pneumatic) with conveyor belt

Bar feeder interface (unimag)

Pneumatic counter-spindle ejector with 100 mm adjustable travel

Coolant supply through counter spindle

Preparation for extraction, connection flange d=200

Optional tool holder

4 x counter spindle tool holders

Parting tool holder

2 x holders for drilling tools 40 mm

2 x reducing sleeves d=25-40

2 x reducing sleeves d=32-40

4 x double boring bar holder d=32

2 x reducing sleeves d=10/32

2 x reducing sleeve d=12/32

2 x reducing sleeves d=16/32

2 x reducing sleeves d=20/32

2 x reducing sleeves d=25/32

3 x double axial holder AGW (max. 8,000 rpm)

2 x radial holder for AGW with internal coolant supply (max. 12,000 rpm)

Loading magazine IRCO Breuning MUK 7012

Transport ex works, here the transfer of risk to the customer takes place.

Customer pays for transport, delivery and installation at the customer’s site

CMZ TA25YS CNC lathe.

Due to a lack of skilled workers, illness and the lack of a successor, production was stopped on March 31, 2023. Some of the machines have already been sold and now the rest.

Price suggestions welcome.