Description

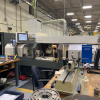

Studer S33 CNC Grinding Machine

Design Details

- Swivable Workpiece-table 8,5°

- Direct Travel measuring system 0,0001mm (linear)

- Dressing unit

- Machine has never been in production, only starting-up

- Condition like NEW!

Technical details/ additional accessories

Centre height 175 mm

Grinding length 1000 mm

Grinding diameter max. 350 mm

Control Fanuc 0iTD

Resolution 0,0001 mm

max. work piece weight between centers 80 kg

Grinding spindle head:

Swivel Table -15 – +225 °

Indexing B axis Automatic 1° Hirth Coupling

Grinding wheel size 500 x 63 x 203,2 mm

Peripheral speed max. 50 m/sec

power capacity 11 kW

Work piece spindle head:

Number of revolutions 1 – 1.500 rpm

Power capacity 1,6 / 3 kW

Spindle passage 30 mm

Fitting taper MK 5

Machine-Datasheet

C-Axis 0,0001 °

Tailstock:

taper of center MK 4

Travel:

x-axis 285 mm

z-axis 1000 mm

feeds:

feed speeds X: 0,001 – 10.000 mm/min

feed speeds Z: 0,001 – 20.000 mm/min

total power requirement ca. 20 kVA

weight of the machine ca. 4,0 t

dimensions of the machine ca. 5,0 x 3,5 x 2,5 m

Documents

hydraulic system

electronic hand wheel

Internal Grinding

Tailstock , 4-Jaw-Chuck

grinding wheels, paper band filter , Coolant system

2 OD wheel,

X and Z SCALE measuring system 0,0001mm

Granitan Base

1 OD, 1 ID, Less than 3500hours

Fanuc 2iTB control

How to buy a Studer grinder?

All machines in the market are not equal. How to test a Studer?

Ways -Foremost is the ways. The machine made in the last 15 years have a type of plastic poured which keeps the oil on the ways. If they are worn out, it takes 400,000 USD to fix them. The machine is pretty much not worth anything. Also find out how much is the wear so that you know the life of the machine at the highest level.

Granitan Cracks- Make sure there was no crash and the base is not broken anywhere. Though I have personally repaired a few cracks, some of them cost 420,000 to repair. It has to go to Switzerland for repair. Here is some cost for you.

B axis -There are a few machines which were made without a curvic coupling and is never going to accurate. The price of a new B axis is about 80,000. So make sure you have the proper B axis.

Scales – Make sure your scales are enabled. The machine can have a ton of back lash. People can turn the scales off and sell it to you. It will not have the same accuracy. Cost could be 15,000 Per axis.

Check the backlash on all the axes. Cost could be 15,000 per axis

Check the play on the work head bearings. Cost could be as high as 25,000.

Wheel head – Check the spindle play. Cost could be 15,000

Tail stock – Check the play – Cost could be 8,000

Electronics , though it is easy to replace, make sure you know what you are getting into. Some components are obsolete.

Communicator – Make sure it works – Cost could be 18,000

Sensitron – Make sure it works – Cost could be 8,000

Gauging – If you are going to use it test it and make sure it is not obsolete. Call the gauge maker and give the model number. They are ultra expensive to change. Cost could be 25,000.

Monitor- Make sure it is good enough – Cost could be 4,000

Coolant tank – Make sure it is the right tank – Cost could be 8,000

Id Spindle – Run it for full speed. Make sure oil drips from the front. Coolant lines are not clogged.- Cost could be 22,000.

Cables and hoses – Sometime the type of coolant can eat it so bad, machine becomes un reliable. The fixing cost could be 20,000.

Carbide – Depending on what was run on the machine the corrosion could be really bad. I have seen in occasion customer has rebuilt the whole machine after 12 years.

Also watch out for machines which come out of auction. Some have sit in water for a while. Make sure you find out who owned the machine last. When was the last time it ran good parts. You might see some machines sitting on the market for a long time. There is always a reason for that.

The cheapest CNC Studer is 300K. This is entry level Luxury. Mid level machine like a S33 with OD and ID feature could be 700K. S31 well appointed could run you into 1 million. S40 well appointed to 1.3 million. Fully loaded into 1.6 million. Options are plenty. Different work heads, center line height, quickset, non round grinding, Thread grinding and many more can tip the price by 100K. Getting any used Studer is a bargain. You can find one. The questions is, did you get what you paid for.

When you buy from us, we give you a report card. You know what you are getting. We will give you a prediction of how long every component will last and a risk mitigation plan of parts for your electronics. You are buying a Ferrari and know what you are getting. Peace of mind comes with knowing what you are getting.

We sell only known good machines; buy from us with peace of mind !

Here is how we evaluate a machine. Our inspection Routine is 10 hours. This includes a detailed report of the machine. This report includes what your machine is worth. What is the maximum, you can pay for that machine of the year. What expenses you can expect in the next 5 years.

When you buy from us, we give you a report card. You know what you are getting. We will give you a prediction of how long every component will last and a risk mitigation plan of parts for your electronics. You are buying a Ferrari, make sure you know what you are getting. Peace of mind comes with knowing what you are getting.

If you decide to buy a machine on a auction of from some one who never dealt with a STUDER, or some one has a shop and sells their used machine, make sure you call UGA and have an experienced tech give a full report. We can do that for you as well. Ask for a how a sample report would look like. It will take a minimum 8 hours to give you a precise report or else you could be spending a minimum of 10K to a 100K. Multiple occasion people could not use the machine and we ended up buying for 10 cents on what they paid. In cases machines looks so well, but the alignment is all off. We had to redo the table for straightness, height, tail stock and work head to match them costing more than 100K. The machine value is not just by the mechanics it is also by the alignment when you are going to hold .0001. Never buy a Studer based on a price.

Coffee beans alone does not make the best coffee, it is the process to get the best output.