Description

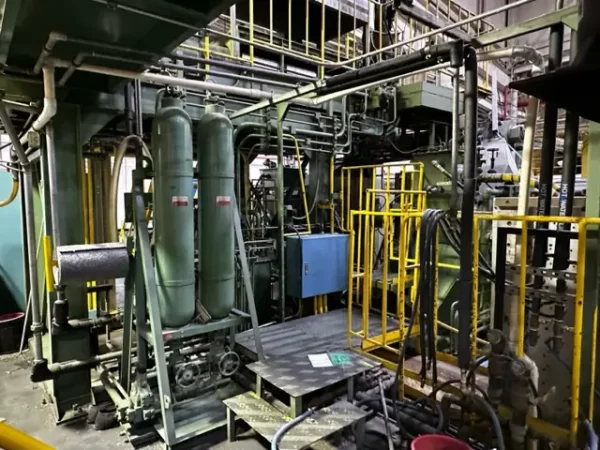

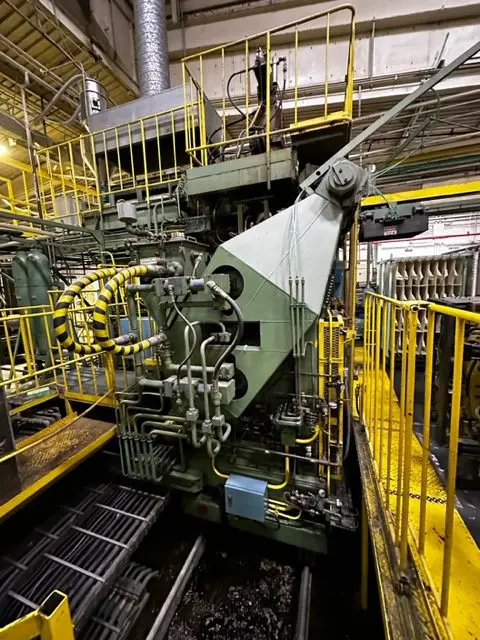

JSW NB60S / P90 / AC75 Accumulator Head Blow Molder

Accumulator blow molding machine

| Make | JSW |

|---|---|

| Model | NB60S / P90 / AC75 |

| JSW NB60S / P90 / AC75 | Accumulator Head Blow Molder |

| Number of Heads | 1 |

|---|---|

| Shot Size Capacity (Liter / lbs.) | 7 Liter ( 15.43 lbs. approx.) |

| Platen Size (mm / inches) | 800mm (31.49″ ) W x 1400mm (55.11″) H |

| Min. / Maximum Daylight (mm / inches) | 400mm (15.74″) to 1100mm (43.30″) |

| Clamping Tonnage | 60 Ton |

| Extruder | |

| Screw Size (mm/inches) | 90mm (3.5″) |

| L/D Ratio | 25:1 |

| Horsepower | 55kw (73.7 hp) |

| Cooled | Air Cooled Barrel |

| Hopper Opening | Water Cooled Feedthroat |

| Controller | MOOG Parison Controller |

What is Accumulator Head Blow Molder Machine?

An Accumulator Head Blow Molder machine, also known as an accumulator blow molding machine, is a type of equipment used in the manufacturing process of plastic containers and bottles. It is a specialized machine that employs the blow molding technique to create hollow plastic products.

The accumulator head blow molder machine consists of several key components:

- Extruder: The machine has one or more extruders that melt and extrude plastic material, usually high-density polyethylene (HDPE), into a molten form.

- Accumulator Head: The accumulator head is a large, hollow metal chamber that serves as a storage reservoir for the molten plastic. It accumulates a specific volume of melted plastic to ensure a continuous supply during the blow molding process.

- Mold: The mold is a cavity that defines the shape and size of the final product. It is typically made from two halves that come together to enclose the molten plastic.

- Clamping System: The machine has a clamping system that holds the mold halves together during the blow molding process. It ensures a tight seal and prevents the molten plastic from escaping.

- Blow Pin: The blow pin is a hollow tube that is inserted into the mold cavity. It allows compressed air to be injected into the molten plastic, causing it to expand and take the shape of the mold.

The operation of an accumulator head blow molder machine involves the following steps:

- Plastic Melting: The extruder(s) melt the plastic material, typically HDPE, and transport it to the accumulator head.

- Accumulation: The molten plastic is accumulated in the accumulator head, which stores a predetermined volume of plastic for each cycle.

- Mold Closing: The mold halves close around the accumulator head, creating a sealed cavity.

- Blow Molding: Compressed air is injected through the blow pin into the molten plastic, causing it to expand and conform to the shape of the mold cavity.

- Cooling and Solidification: The blown plastic is cooled with air or water to solidify and retain its shape.

- Mold Opening: The mold halves separate, and the finished product is ejected from the machine.

Accumulator head blow molding machines are commonly used to produce large plastic containers such as drums, industrial containers, automotive components, and other hollow plastic products with complex shapes. The advantage of using this type of machine is the ability to produce large-sized products with high precision and consistency.