Description

FLUTEBOX MEGA 1400 3PLY – Year 2023

FLUTEBOX MEGA 1400 3 layer Corrugated Board Production Line

For Heavy Duty Packaging Boxes Paperboard

Hydraulic Mill Roll Stand

Structure and Features:

1. Clamping Moving Right-Left Arms UP-Down and Paper Roll Rotation is Hydraulic Drive

3. Each machine has two guide rail and two Trolley for feeding paper;The guide rail is

welded with channel 5″ channel steel and guide column. The paper trolley is welded with 1. 0mm steel plate, the length of the guide rail is 4500mm.

Spec of stand:

1. Clamping paper range: max. 1400mm min. 500mm

2. Paper roll diameter: max. ¢1250mm min. ¢300mm

3. Single side max. bear load: max. 800kg.

Spec of electric motor:

1. Reel Paper Nipping Motor Power: 2 HP *3pcs

Kraft Paper Feeding Ground Rack & Trolly

Structure and Features:

1. To feed the Kraft paper to reel stand.

2. The whole body of rack is under the ground, main frame: Model 10 channel steel with ¢ 20mm drawing

barweld together, overall length 4500mm.

3. Two racks for one reel stand to feed the Kraft paper at both side.

Double Pre-heater

Structure and Features:

1. The pre-heater roller is under the stander of the 1st class (grade) pressure vessel of the national.

2. All the surfaces of every rollers have been ground with high accuracy and Grinding plated to less the resistance of paper preheating, long service of using life.

3. Menual to enlarge the preheating area, preheating area can be adjusted in 360°

Common Spec:

1. Working Width: 1400mm

2. Diameter of the Preheater cylinder:Φ600mm

3. Preheating adjusting area by Manual: 360°

4. Diameter of the roller for preheating adjusting area by electric: Φ85mm

Fingerless Single Facer

Structure and Features:

Glue Rollers:

Diameter

Φ215mm

Processing Way

Surface of glue roller is ground, then with 25 line rut type net dot, then plating chrome

Surface of glue balance roller is ground then plating chrome

Control Way

Cylinder control of the Lifting Up-down

Glue Supply

Glue circulating system(storage tank with glue pump)

Corrugated Rollers:

Diameter

Down Roller:Φ280mm

Material

EN19high quality alloy steel, rigidity HRC55°-58°

Flute Type

(U/V) ACB

Heating way

Steam heating

Press Rollers:

Diameter

Φ290mm

Material

medium steel (EN9)45#

Processing Way

The surface is Grinding plating

Control Way

Cylinder control of the Lifting Up-down

Preheater Rollers:

Diameter

UP Roller:280 mm

Material

seamless steel tube

All connected by flexible metallic tubes

Common Spec:

Style of Transmit cardboard

Vacuum Cover absorbable style, Hight pressure Draw fan.with wind control Adjusting & noise deadening device.

Style of Control Roller

Pneumatic control the upper roller, pressure roller and glue roller

Driving Way:With frequency inverter

Common Spec:

1. Effective width:1400mm

2. Operation direction: left or right(determined in accordance with customer plant)

3. Design Speed:100m/min Working Speed: 80m/min

4. Temperature: 160—200℃

5. Corrugated flute:(UV type or UVV type)

Spec of Motor:

1. Main drive motor: 7.5KW Rated voltage:380V 50Hz Continuous (S1) working standard

2. Suction motor: 7.5KW Rated voltage:380V 50Hz Continuous (S1) working standard

Single Gluer Machine

1. After the glue roller surface quenched, bore machining, surface grinding and doing balancing engraved pit style textured, coating evenly, consume less glue.

2. Upper pressure Roller Pneumatic adjust gum setting manual

3. All Gum Roller Hard Chrome

Common Spec:

1. Preheater cylinder temperature range: 150—180℃

2. Pneumatic system: 0.4—0.7Mpa

Rollers’ Diameter:

1. Glue roller:Φ215mm Glue amount adjusting roller:Φ1400mm

2. Down preheater roller:Φ280mm Up preheater roller: Φ280mm Paper roller:Φ85m

Single Conveying Bridge

Structure and Features:

1. The Main Frame is connected with channel steel, and angle steel.

2. With Protecting Handrail on Single sides and safety pedal, the operation side is installed with safety ladder, to make sure the safety and convenience of the worker.

3. Vacuum suction tension control, suction pipe with adjusting valve, draw fan power can be adjusted freely.

4. Correct the position by double guide posts, correct parts are driven by screw , fast and accuracy to position, steady to move.

Spec of the rollers:

1. Paper feeding rollers & tension rollers: Φ127mm transport rollers:Φ110mm

2. Main tension drive rollers: Φ127mm paper pass rollers and paper guide rollers: Φ110mm

3. Paper feeding rollers with belts: Φ110mm

Spec of Motor:

1. Single face sheet draw motor: 3kw, 380V 50Hz Continuous (S1) working Type

2. Draw Fan Motor: 3kw, 380V 50Hz Continuous (S1) working Type

3. Paper width adjusting speed reducer: 250w 380V 50Hz Short time (S2) working Type

Double Facer

Structure and Features:

1. Hot Plates’ surfaces Grinding plated, width : 600mm. Total 10 pieces of hot plates

2. Hot plates adopts the compressed press rollers structure. Pressure roller lifting adopt pneumatic structure

3. Up convey belt left and right correct by auto with both sides, tension adjusting system; down belt manual small amount adjust.

4. Drive rollers’ surface is wrapped by rubber, Y shape structure, with middle height, to make sure the board can be out smoothly

5. Main drive motor: Variable frequency motor, high force when low speed start, high speed adjusting range, steady to use, easy to mend.

6. Up belt adopt double cylinder S type tensioning device

7. Under belt adopt S type manual correct tensioning device.

Common Spec:

1. Temperature requirement: 160—200℃

2. Air pressure: 0.6—0.9Mpa

3. Cool shaping length: 4m Heating plates 10 pieces

Spec of Motor:

– Main Drive Motor: 20kw Frequency

Nominal voltage: 380V 50Hz Continuous (S1) working Type.

Electric Slitter Scorer

Structure and Features:

1. Overcome the phenomenon of collapse the board when crop, smooth cutting, and the quality is improved

2. The machine can move left and right, adjust by cyclical reducer.

3. Cutter and line pressing adjustment convenient, error is ±0.5 mm, with automatic sharpening device

4. Blades 8 lines type, blade is made of tungsten alloy steel, life is more than 30,000 m

Technical parameter:

1. Max. width :1600mm

2. Specification: 4 knives 8 lines

3. Min. Cut width: 135mm

4. Max cut width: 1500mm

Motor:

1. Knife motor: 0.4KW 2. Knife driver motor: 5.5KW

Cut Off Machine

Structure and Features:

1. Cutting length: 500 mm-3000 mm. Cutting precision:±1.5 mm.

2. Knife shaft gear using precision forging steel material high frequency quenching, lateral clearance transmission, adopt the keyless connection mode, high driving accuracy.

3. Helical knife structure, type saw tooth knife, decrease cutting obstruction, low noise.

4. Balance treatment, high quality alloy steel for blade shaft, which helps to keep it good stability.

5. Sun-shape wheels press cardboard in the front and the rear conveyer. The transporting is stable and with even pressure, which avoid jam caused or broken cardboard.

6. Precision adjustable gap gear, ensure blade precision engagement, running balance.

7. Machine base and wall panel adopt the Grey cast iron, good rigidity, strong vibration resistance.

8. The servo controller control the servo motor, INDIA Eview 10.4 inch touch screen

Technical parameter:

1. Working width: 1400mm

2. Design Speed: 100m/min Working Speed: 80m/min

3. Min. cut length: 500mm 4.Max cut length: 9999mm

5. Cut precision: uniform velocity ±1mm, non-uniform velocity ±2mm

Motor:

1. Main motor:16kw Ac synchronous servo

2. Feeder motor:2kw(Frequency control the speed)

3. Lubricating oil pump motor:0.25kw

L Type Stacker unit

1. Weld by 5# Channel steel electric to adjust the size of the board pneumatic to control the out Put on transverse direction output speed can be adjusted electrically

2. Automatic count the number of cardboard

3. Main feeding frequency variable Motor 2 k.w

4. Transverse direction motor 1.5 k.w

Paper/Plastic Bag Machines

Paper

Boilers

Printing

Processing

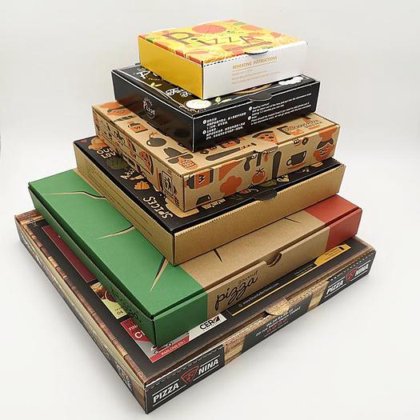

Corrugated

Paper board

Corrugated box

Corrugating paper

Corrugation plant

Paper cup machines

Cartoning machines

Packaging machinery

Corrugation machine

Cardboard box maker

Coating & laminating

Paper-making machines

Corrugated box machine

Cardboard box making machine

Corrugated box making machine

Toilet paper & napkin machines