Description

MATTEUZZI RAS 90-DC Complete Tire Retread Plant – Year 2004

Complete tire retread plant built between 2004-2014

Production plant for 30,000 cold retreaded tires per year

PRICE including installation and commissioning

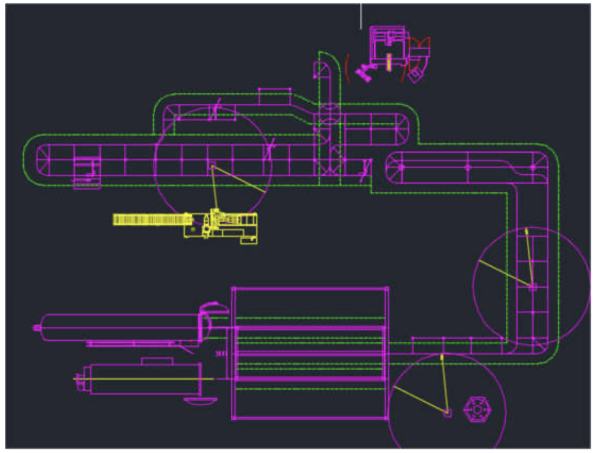

-Rail system “Helm 500” frames/supports manufacturer TRM

-Rail length approx. 110m, rail height approx. 2m

– 76 hooks with rollers – Various switches

– 3 processing stations including suction connections

– Spray tunnel for rubber solution incl. extraction

– Matteuzzi RAS 90 DC 4 spreader

– Matteuzzi RAS 98-E ULTRA spacer

– CISAP CONE 1

– Bandag broaching machine

– Autoclave station for two 24 autoclaves with 139 hooks (long+short) model TRM

– 24 TRM autoclave + 18 Scholz autoclave

– Suction unit with filter for connection to a roughage container

– 4 cranes with swivel arm for chain hoists

– Compressed air system compressor + pressure tank + refrigeration dryer

– Pressure tester Matteuzzi G 100 high pressure tire tester

– Compressed air lines

– Other accessories, various machines as seen

– 2x inlet control spreader Matteuzzi, ISP 540/2 tire inspection spreader

Pressure tester Matteuzzi G 100 / high-pressure tire tester

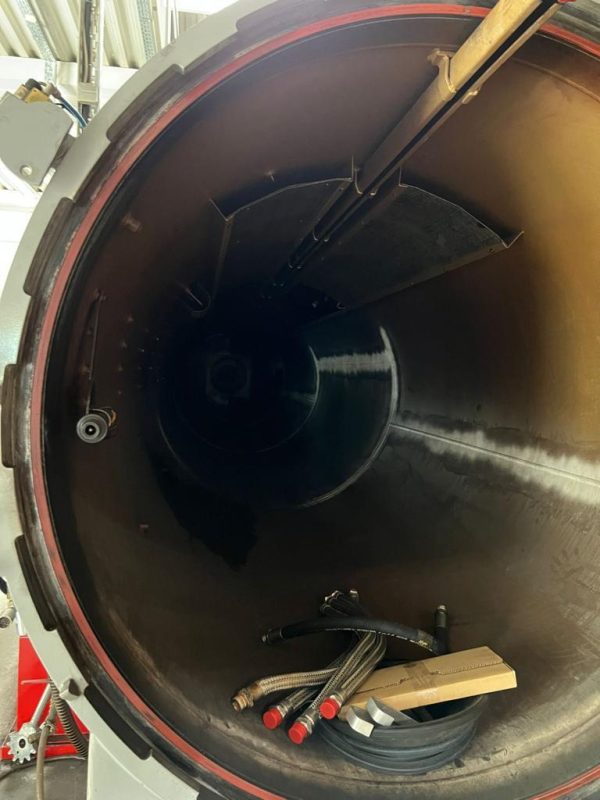

– Sherography system SDS ITT No. 158 / Sherography system

– CNC polishing machine Matteuzzi RAS 90 DC 4, CNC controlled polishing machine

– Bandag 23X polishing machine / manual polishing machine

– Plate extruder SH BAZ 2160 with rims / extruder builder

– Outer shell vertical spreader / outer shell spreader

– Automatic autoclaving station for 2x 24 tire autoclaves, 3 rails / Full-Fill-Matic for 2x 24 tire autoclaves, with 3 monorails

– Autoclave TRM 24er / 24 tire autoclave

– Autoclave Scholz 18 / 18 tire autoclave

– eepos lifting device for rolls up to 150kg, 30mx10m / lifting device for material up to 150kg

– Tread preparation table with cutting device / tread preparation table incl. manual tread cutter

– Compressed air system compressor + pressure vessel + refrigeration dryer / compressed air system compressor + pressure vessel + refrigeration dryer

– Inner sleeve cabinet / inner sleeve storage

– Spray Booth Tire Finish / Spray Booth Tire Finish

– Suction system with filter for connection to a roughage hopper Suction system with filter for connection to a roughage hopper

+ raw materials such as approx. 50,000 kg. Treads from various premium manufacturers such as Recamic, Kraiburg and Bandag (value approx. 500,000) and much more