Description

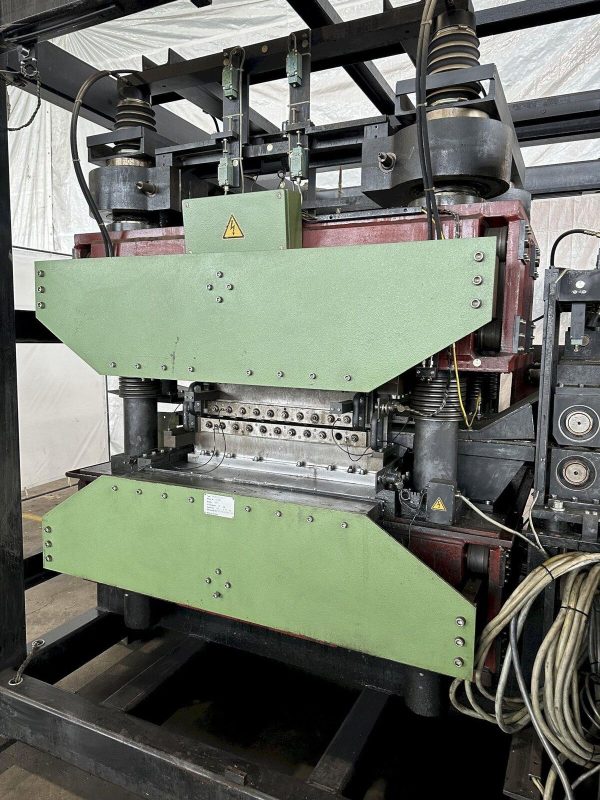

KOHLER KRM65.500/21B – Year 1994

Precision Leveler Machine 24″ X .510″

BRAND…………………………….: KOHLER

MODEL…………………………….: KRM65.500/21B

CAPACITY………………………….: 24″ X .510″ MAX (WIDTH X THICKNESS)

CAPACITY………………………….: 12″ X .669″ MAX (WIDTH X THICKNESS)

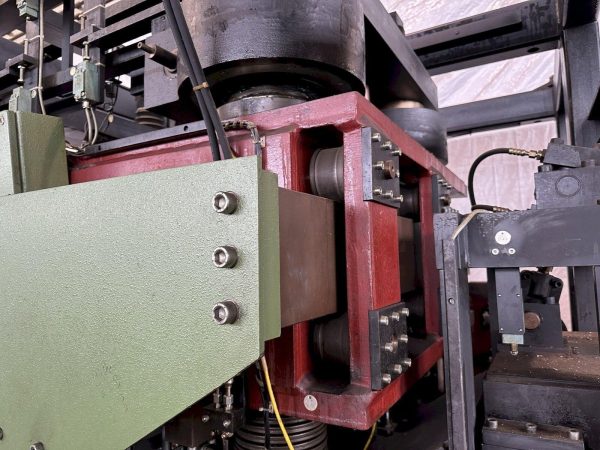

# OF ROLLS………………………..: 21 (10 OVER 11)

What is Precision Leveler Machine?

A Precision Leveler Machine, also known as a Leveling Machine or Leveler, is a mechanical device used in various industries to straighten and flatten metal sheets or coils. It is commonly employed in manufacturing processes where flatness and dimensional accuracy are critical, such as in the production of automotive parts, electrical appliances, construction materials, and metal components.

The main purpose of a Precision Leveler Machine is to remove or reduce residual stresses, shape irregularities, and distortions that may exist in metal sheets or coils. These imperfections can be caused by various factors such as rolling, cutting, welding, or thermal processes during the manufacturing or handling of the material. The leveler applies controlled forces to the metal, exerting pressure and tension to correct any deviations and bring the material to the desired flatness.

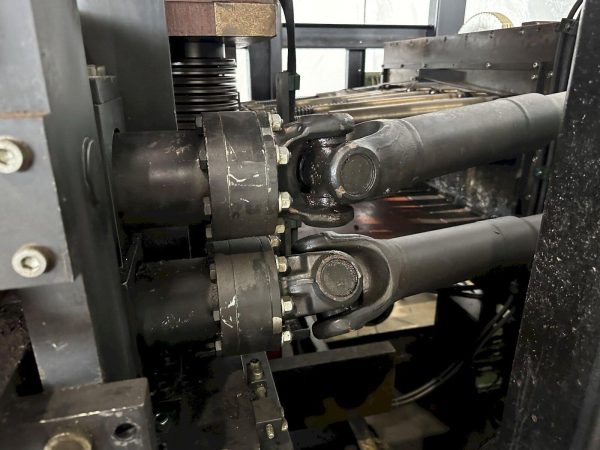

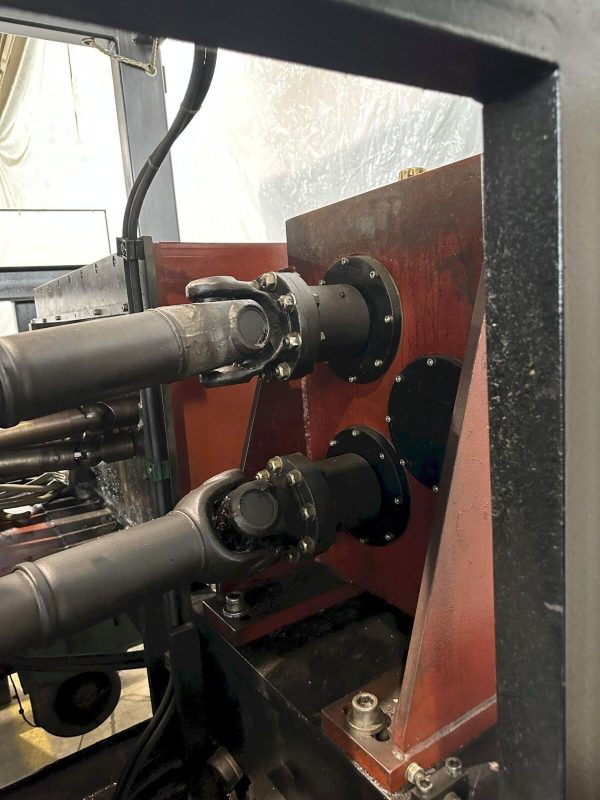

The machine typically consists of a series of roller arrangements, with upper and lower sets of rollers positioned in an alternating manner. The rollers apply pressure and bending forces to the metal as it passes through the machine. The leveler’s design allows it to adjust the distribution of forces across the width and length of the material, effectively leveling it out.

Modern Precision Leveler Machines often incorporate advanced technologies such as hydraulic or servo-driven systems, computer controls, and sensors to ensure precise and accurate leveling. These machines can handle a wide range of metal materials, including steel, aluminum, copper, and alloys, and can process different thicknesses and widths depending on their design and capabilities.

By using a Precision Leveler Machine, manufacturers can achieve flat, uniform, and dimensionally accurate metal sheets or coils, meeting the required specifications for their intended applications. This improves the quality and performance of the final products and facilitates downstream processes such as cutting, bending, stamping, or welding.