Description

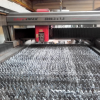

Ermaksan Lasermak 4000.3 X 1,5 – Year 2010

Laser cutting machine 4000W

| Metal length | 3000 mm |

| Power | 4000 W |

| Metal width | 1500 mm |

| Type | CO₂ |

| Option to cut tubes | no |

| Max thickness | 20 mm |

| CNC | yes |

| CNC type | FANUC Series 16i-LB |

| Travel X | 3060 mm |

| Travel Y | 1540 mm |

| Travel Z | 150 mm |

| Max weight of the workpiece | 1500 kg |

| Ermaksan Lasermak 4000.3 X 1,5 | 5-osi laser cutting machine |

| Length x width x height | 10470.0 × 5285.0 × 2430.0 |

| Weight | 19500 kg |

Technical parameters of the ERMAKSAN LASERMAK 4000.3 x 1.5 cutter

– number of axes: 5 (X,Y,Z,U,V)

– laser power: 4 kW

– laser type: CO2

– feeds in the X/U/Y/Z/V axes: 3060/3060/1540/150/2250 mm

– acceleration in the X, U, Y, Z axes: 2/2/3/2 G

– maximum axis speeds (with simultaneous drive operation): 169 m/min

– maximum speed of the X axis (single): 120 m / min

– maximum speed of the Y axis (single): 120 m / min

– maximum dimensions of the detail (length x width): 3000 x 1500 mm

– maximum cutting thickness (mild steel): 20 mm

– maximum cutting thickness (stainless steel): 12 mm

– maximum cutting thickness (aluminum): 8 mm

– maximum workpiece weight: 1500 kg

– positioning accuracy: ± 0.03 mm/m

– repeat accuracy: ± 0.015 mm

– power stability: ± 2%

– length of the laser beam: 10.6 μm

– number of pallets: 2

– pallet exchange time: 35 s

– maximum pulse peak power: 5000 W

– laser gas consumption: 10 l/h

– cooling water flow: 160 l/min

– power demand: 50-70 kW

– dimensions (length x width x height): 10470 x 5285 x 2430 mm

– laser weight LASERMAK 4000.3 x 1.5: 19500 kg

Equipment for the LASERMAK 4000.3 x 1.5 laser cutter

– CNC controller: FANUC Series 16i-LB

– laser source: FANUC C4000i-B

– CAD/CAM software: LANTEK EXPERT CUT

– cutting head: PRECITEC HP 1.5 ”

– automatic pallet changer

The ERMAKSAN LASERMAK 4000.3 x 1.5 5-AXIS laser, built in 2010 in Turkey, is used for cutting details made of mild steel, stainless steel and aluminum. The machine is equipped with a reliable FANUC C4000i-B resonator, generating a 4 kW laser beam, with the help of which laser cutting is characterized by the highest efficiency, precision and quality.

Machining of details with a maximum weight of 1500 kg is performed on a large working table in 5 axes (X,Y,Z,U,V). All axes are equipped with linear motors, offering high feed speed and maximum acceleration. As a result, the efficiency and productivity of the laser, while reducing operating costs, is significantly increased.

The LASERMAK laser cutter uses the PRECITEC HP 1.5″ cutting head with a system of very practical and easy-to-use plug and play cartridges for cutting under high pressure. Using this head, changing the thickness of the material and preparing the settings for the next cut takes only a few minutes.

The ERMAKSAN CO2 laser is also offered with LANTEK EXPERT CUT CAD/CAM software, with which it is possible to calculate the cutting time and its costs, as well as save cutting parameters and technological diagrams for each part in the program. The total weight of the machine is 19500 kg.