Description

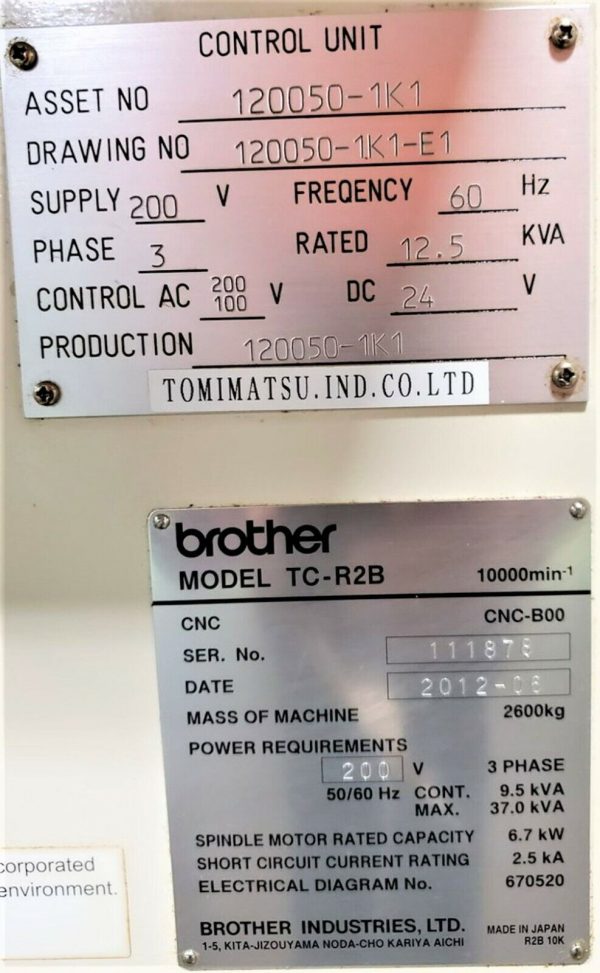

BROTHER TC-R2B – Year 2012

CNC DRILL TAP VERTICAL MACHING CENTER

Specifications

X 16.5

Y 12.6

Z 12.0

RPM 10000.0

# ATC 14.0

Taper 7/24 #30

Table Size: 23.6″ x 16.5″ (each side)

Table Capacity: 256 lbs (one side)

Table Position Time: 2.9 S/180 deg.

X-Axis Travel: 16.5″

Y-Axis Travel: 12.8″

Z-Axis Travel: 12″

X-Axis Rapid Feedrate: 1969 ipm

Y-Axis Rapid Feedrate: 1969 ipm

Z-Axis Rapid Feedrate: 1969 ipm

Cutting Rate: 394 (X, Y) 787 (Z)

Spindle Speed: 10,000 IPM

Spindle Taper: 30

Main Motor: 15 HP

Travel Distance

X-Axis 420mm

Y-Axis 320mm

Z-Axis 305mm

Distance from table top surface to spindle and face

Table work area 200-505mm 8”-20”

Work area size 600 x 300 23.6 x 11.8”

Max. load weight (uniform load) 120 kg.

Spinlde spee (min) 10-10,000

Spinlde speed when tapping (min) 6,000 Max.

Spindle taper hole 7/24 Taper No.30

Feed Rate

Rapid traverse rate (m/min) 50x50x50 m/min

Cutting feed rate (m/min) 1-10,000 mm/min

Z Axis 1-20,000 RPM

ATC

Tool shank type MAS.BT30

Pull stud type MAS.P30T-2

Tool storeage capacity (pcs) 14

Max. tool length 200mm

Distance from taper gauge/max. diameter 30-150/D80 mm

160-200/D40 MM

Max. Tool weight (total weight 25) 3.0 kg.

Tool selection method Randaom short cut

Tool change time

Tool to tool .09

Chip to chip 1.7

Motor

Spindle motor (continuous for 30 min.) 10.1/6,7

Feed axis motor 1.0 kw xy 1-5 kw z

(CONT.)

Machine Dimensions

Height 2,588mm

Installation are 1,617 x 2,658 mm

(when control box is open) 1,456 x 2,644 mm

Weight (including box and splash guard) 2600 kg

Equipped With

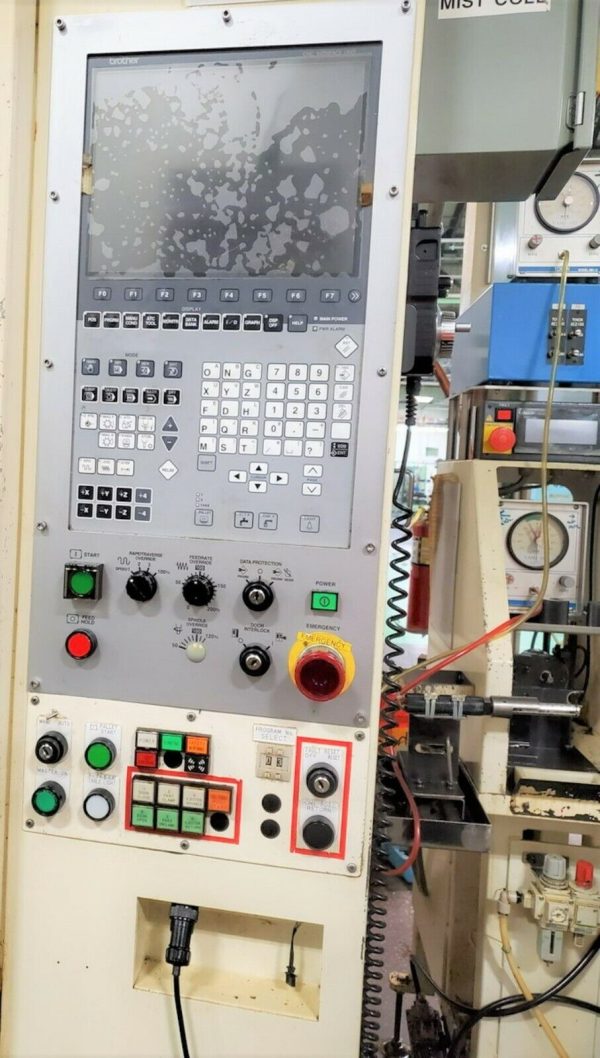

CNC-BOO CNC Control

14 Position turret

180-degree pallet changer

Chip conveyor

Coolant system

BROTHER TC-R2B CNC DRILL TAP VERTICAL MACHING CENTER 180 DEGREE PALLET CHANGER