Description

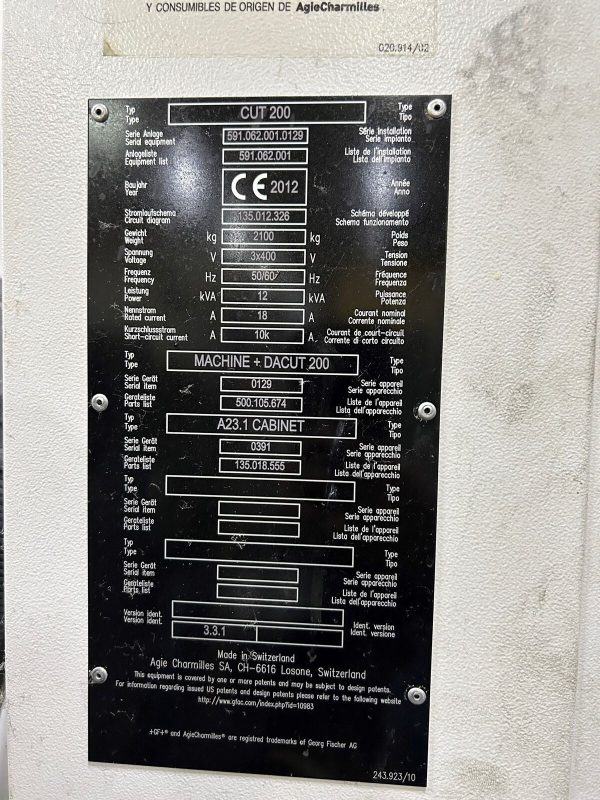

AGIECHARMILLES CUT 200 P – Year 2012

Type: Wire EDM

Brand: AGIECHARMILLES

Model: CUT 200 P

Year: 2012

X – Axis: 13.77″

Y – Axis: 8.66″

Z – Axis: 8.66″

Auto Threading (Yes/No): Yes

Submerged (Yes/No): Yes

SPEC SHEET:

Manufacturer Catalogue Information

X,Y,Z Travel: 350x220x220mm

U,V Travel: 350x220mm

Taper Angle Height: 25/80°/mm

Worktank Door: Swing door

Type Of Machining: Submerged

Machine Dimensions width x depth x height: 2030 x 2850 x 2200mm

Total Weight: 3500kg

Workpeice Dimensions wxdxh: 1000x500x220mm

Max Workpeice Weight: 750kg

Available wire diameters (Standard): 0.30 – 0.15mm

Available wire diameters (Optional): 0.10mm

Permissible weights and types of spools (ISO): 1.6 (K100) – 8 (K160)kg

Min. finishing: 0.1μm Ra

Make: Agie Charmilles

Model: Cut 200P

Serial No: 591.062.001.0129

Year New: 2012

Condition: Used,

Overall In Great Shape 400V 3 phase power, 12 kVA.

Includes Transformer to go from 240/480 to 400V

• Stratus Controls Cabinet AC Unit

• Advantage Model M1-2A-CH water chiller – new 7/2012

• Machine On Total Time: 22266 Hours

• Machine Generator on total time: 3438 Hours

Swiss machine tool manufacturer GF Machining Solutions partners with space exploration leaders like NASA and the European Space Agency, and global precision component manufacturers for turbine blades, airframes, and landing gear parts.

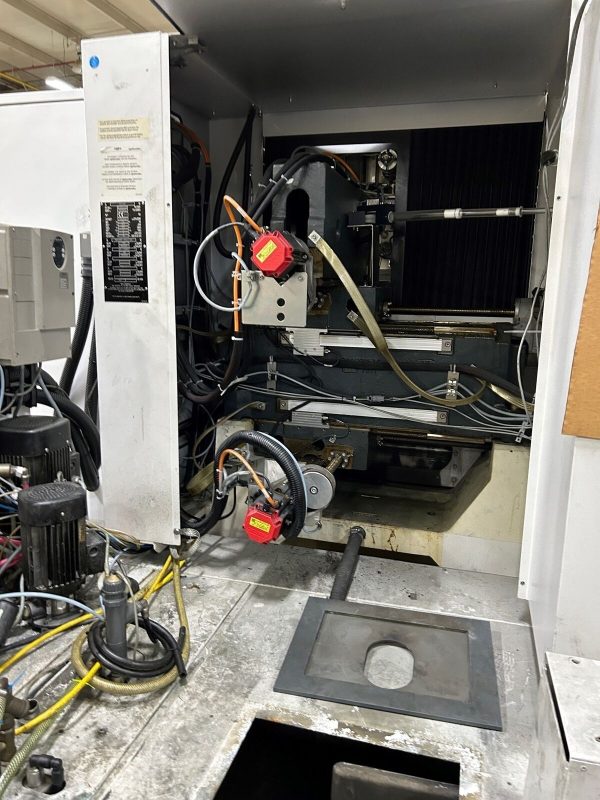

The AgieCharmilles CUT 200 Dedicated, designed to reduce non-cut times, features fast axis speeds, integrated collision protection, and quick wire threading.

The latest Agie Charmilles spark generators enable cutting speeds up to 400 mm²/min and 30-degree tapers in Z-axis height while minimizing heat-affected zones in aerospace alloys.

Energy-saving features and advanced software lower operational costs and enhance system connectivity. CUT 200 Dedicated: suited for aerospace, die/mold, and medical applications.

Built-in A/B tilt/rotary table in CUT 200 Dedicated for complex aerospace alloy components, utilizing C-axis rotation and +/- 20-degree B-axis tilt.

The machine excels in speed, performance, quality, and productivity, controlling production costs in aerospace, mold and die, medical, and contract machining industries.

GF Machining Solutions offers comprehensive Customer Services including Machine Support, Operations Support, and Business Support, providing expertise, spare parts, helpline, and training for increased productivity and competitiveness.