Description

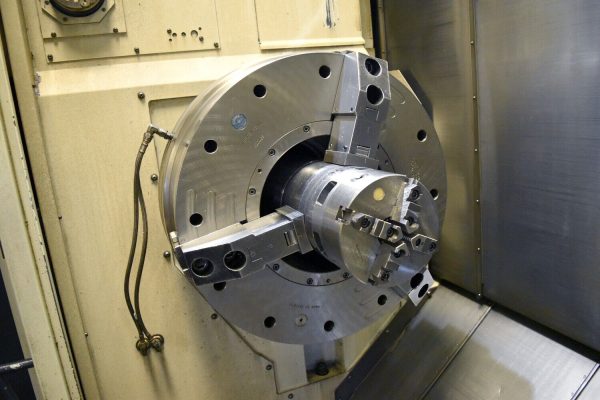

Mazak Integrex E650H – Year 2005

CNC MultiTasking Turn-Mill 5-Axis Milling / Turning Center

LIVE TOOLING / MILLING

C-Axis: Equipped With

Y-Axis: Equipped With

Live Tooling / Milling: Equipped With

B-Axis: Equipped With

SPECIFICATIONS

X-Travel: 40″

Z-Travel: 122″

Distance Between Centers: 120″

Max Swing Over Bed: 36″

Max Turning / Cutting Length: 121″

Max Cutting / Turning Diameter: 36″

SPINDLE

Bar Capacity: 10.20″

Chuck Size: 24″

Chuck Type: Air

Chuck Description: Schunk 3-Jaw Air Chuck

Spindle Bore: 10″

Spindle Speed: 1,000 RPM

Spindle Motor: 50 HP

Spindle Nose: A2-11

TURRET

Tool Positions: 80

Live Milling Max RPM: 10,000 RPM

CONTROL

Control Make/Model: Mazatrol 640M Pro CNC Control

Control Options: Synchronized Tapping

Additional Control Options: Milling Spindle Synchronized Tapping

Absolute Positioning System

Thread Start Point Compensation

Re-Threading Function

Hobbing

TAILSTOCK / STEADYREST

Tailstock: Equipped With

Programmable Tailstock: Equipped With

Steadyrest Type: Hydraulic

Steadyrest Capacity: 12″

OPTIONS

Machine Options: Transformer;Mist Collector;Tool Eye

Additional Machine Specs: Buyer Responsible to Verify All Specifications

Travels:

– Y-Axis: 25.6″

– B-Axis: 0.0001 Degree/Contouring

– C-Axis: 1000 RPM

SMW Autoblock Hydraulic Steady Rest: 1.7″ – 12.2″

LNS SMW Model SLU Z 5.1/Z

Elevated Chip Conveyor

Boring Bar Stocker & 3 Boring Bar Attachment: 100MM & 80MM

Prep for Multi & Flash Tool System

Prep for MMS-B Optical Probe

Prep for 1000 PSI Super Flow Coolant

Coolant Thru Milling Head

Multitap Transformer

Modification for Rear Chuck Mount

Renishaw Tool Eye Probe System

Filtration System

Boring Bar in Photo Not Included

Tooling Not Included

Coolant Types: Thru-Spindle Coolant;High Pressure Coolant;High Pressure Thru-Spindle Coolant

Chip Removal: Chip Conveyor

Probe Make/Model: Renishaw