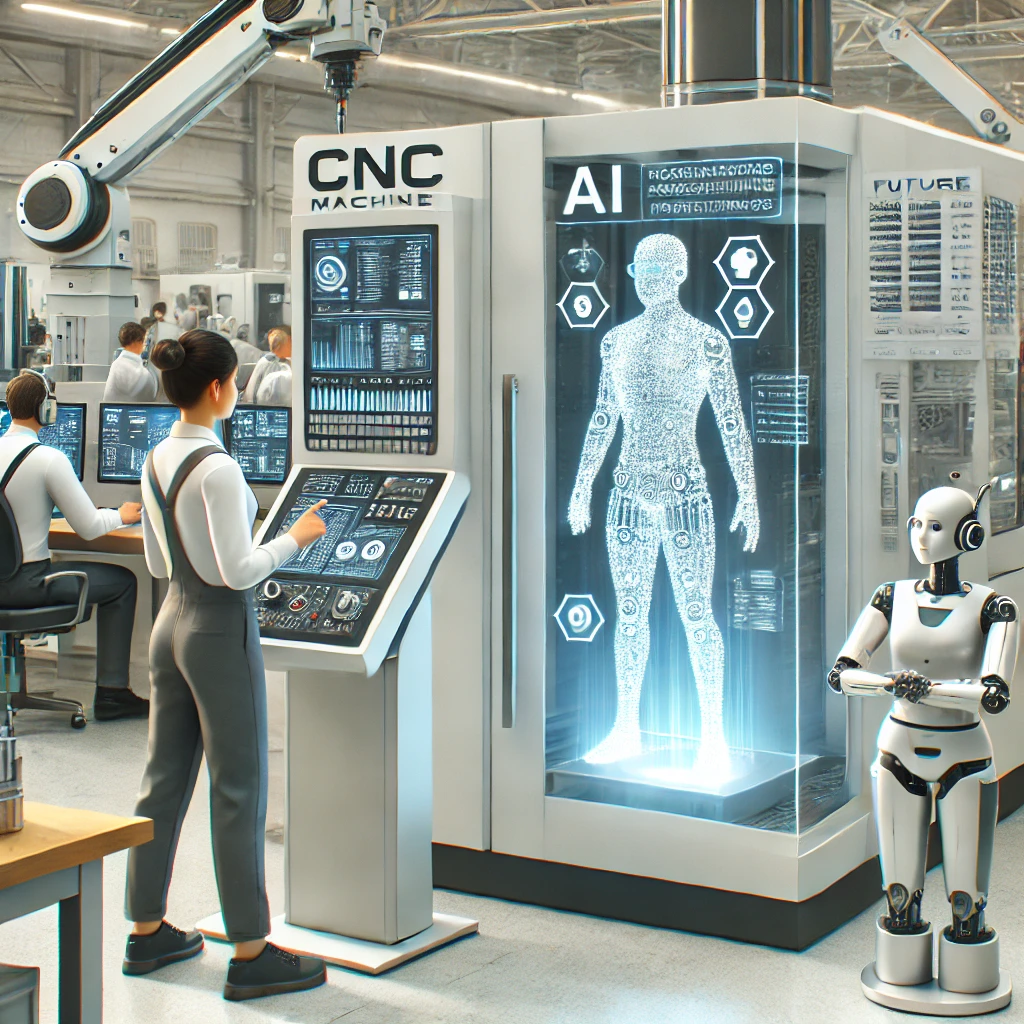

How will the development of artificial intelligence affect CNC operators?

The development of artificial intelligence (AI) is poised to significantly impact CNC (Computer Numerical Control) operators in various ways. Here are some key areas where AI could influence their roles:

1. Automation of Routine Tasks

- Increased Efficiency: AI can automate many routine tasks currently performed by CNC operators, such as tool changes, machine setup, and routine maintenance checks. This could reduce the need for manual intervention, allowing operators to focus on more complex tasks.

- Job Shift: As AI takes over routine tasks, the role of CNC operators may shift towards overseeing and managing AI-driven processes, requiring them to acquire new skills.

2. Enhanced Precision and Quality Control

- Real-Time Monitoring: AI can monitor machining processes in real-time, detecting anomalies or deviations with higher precision than humans. This enhances product quality and reduces waste.

- Predictive Maintenance: AI can predict when a machine might fail or need maintenance, reducing downtime and improving overall efficiency. CNC operators will likely need to work closely with these systems to ensure smooth operations.

3. Skillset Evolution

- Training on AI Systems: CNC operators may need to learn how to interact with AI systems, including understanding how to set parameters, interpret AI-generated data, and troubleshoot AI-related issues.

- Higher Technical Skills Required: The integration of AI could lead to a demand for operators with more advanced technical skills, such as programming, data analysis, and understanding of AI algorithms.

4. Human-AI Collaboration

- Decision Support: AI can assist operators in decision-making by providing data-driven insights and recommendations, making complex machining processes more efficient.

- Complex Problem Solving: While AI can handle routine tasks, CNC operators will still be essential for solving complex problems, handling non-standard tasks, and making nuanced decisions that AI might not yet be able to address.

5. Job Market Impact

- Job Redefinition: Some CNC operator roles may be redefined or even reduced as AI takes over certain tasks. However, new roles related to AI management, maintenance, and optimization could emerge.

- Increased Productivity: Companies may see increased productivity, leading to potential job creation in other areas, such as AI system development, integration, and maintenance.

6. Safety Improvements

- Enhanced Safety: AI can improve safety by monitoring machine conditions and operator behaviors, alerting them to potential hazards, and even taking corrective action if necessary.

- Reduced Human Error: With AI handling more precise and repetitive tasks, the potential for human error could decrease, leading to safer and more consistent operations.

7. Customization and Flexibility

- Adaptive Manufacturing: AI allows for more flexible and adaptive manufacturing processes, enabling CNC machines to quickly switch between different tasks or customize products without extensive reprogramming.

- Operator Input in Customization: Operators might play a crucial role in providing inputs for AI-driven customization, ensuring that machines meet specific customer requirements.

Conclusion

The development of AI is likely to transform the role of CNC operators from performing routine tasks to managing and interacting with sophisticated AI systems. While this may lead to reduced demand for traditional CNC operator roles, it could also create opportunities for those who are willing to adapt and learn new skills in AI, programming, and machine management. The overall impact will depend on how the industry and workforce adapt to these changes.